Plate packaging machine for installing polar plates

A technology of cladding machine and pole plate, which is applied in the direction of electrode manufacturing, electrode carrier/current collector, sustainable manufacturing/processing, etc., can solve the problem of low working efficiency of battery pole plate cladding, achieve saving equipment investment costs, improve The effect of working efficiency and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

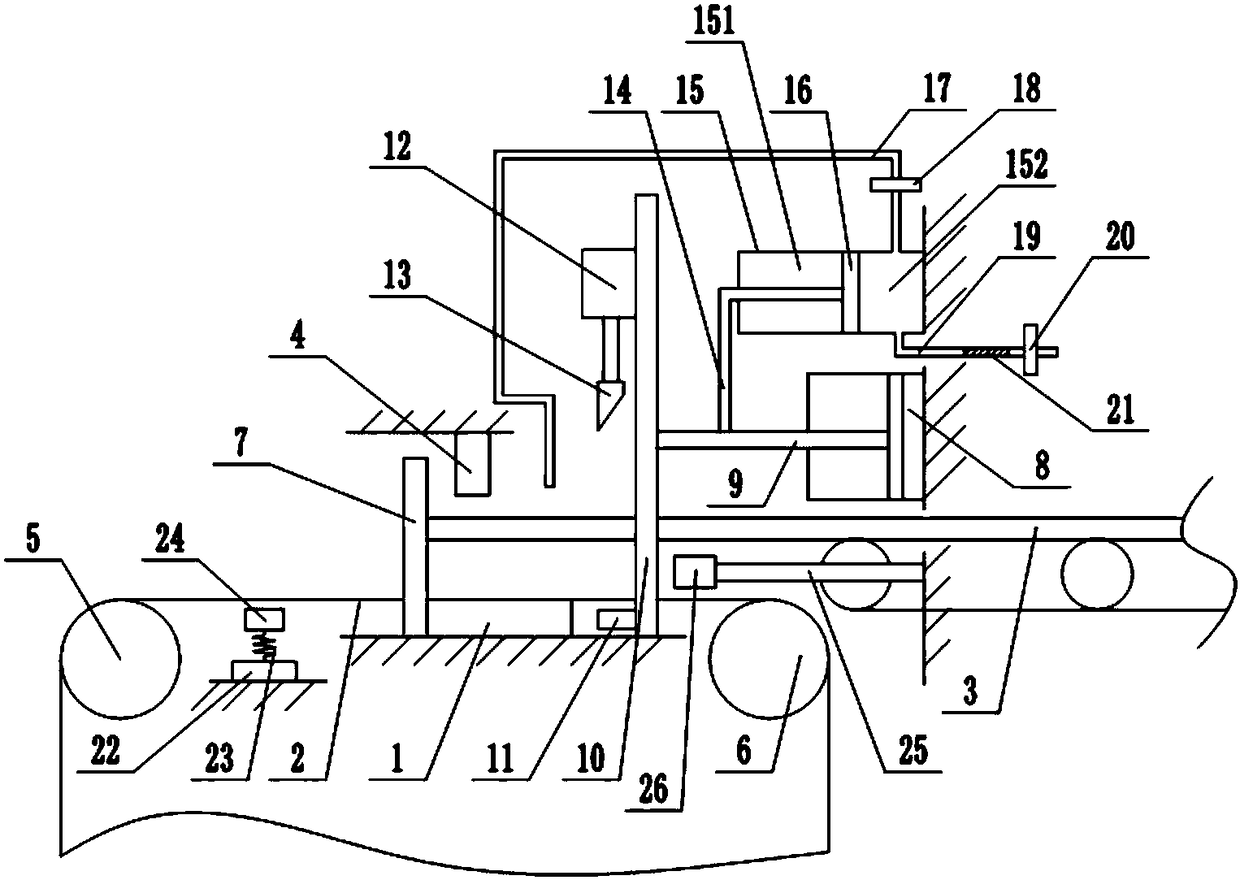

[0019] The reference signs in the drawings of the specification include: battery plate 1, glass fiber film 2, separator 3, stamping head 4, driving wheel 5, driven wheel 6, baffle plate 7, telescopic cylinder 8, piston rod 9, slide plate 10 , probe plate 11, lifting cylinder 12, cutter 13, connecting rod 14, cylinder body 15, first chamber 151, second chamber 152, slider 16, air inlet pipe 17, first one-way valve 18, air outlet pipe 19 , the second one-way valve 20, filter layer 21, electromagnet 22, spring 23, magnet 24, automatic expansion rod 25, detection mechanism 26.

[0020] This embodiment is basically as figure 1 As shown, the cladding machine for installing the pole plate includes a frame, a transmission mechanism for transmitting the separator 3, and a driving wheel 5 and a driven wheel 6 for transmitting the glass fiber film 2. The frame is fixedly connected with a telescopic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com