Preparation method and application of black blue perovskite thin film

A perovskite, blue-black technology, used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems such as damage to the performance of photovoltaic cells, and achieve the advantages of inhibiting the formation of delta phase, simple operation, and improving crystal quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

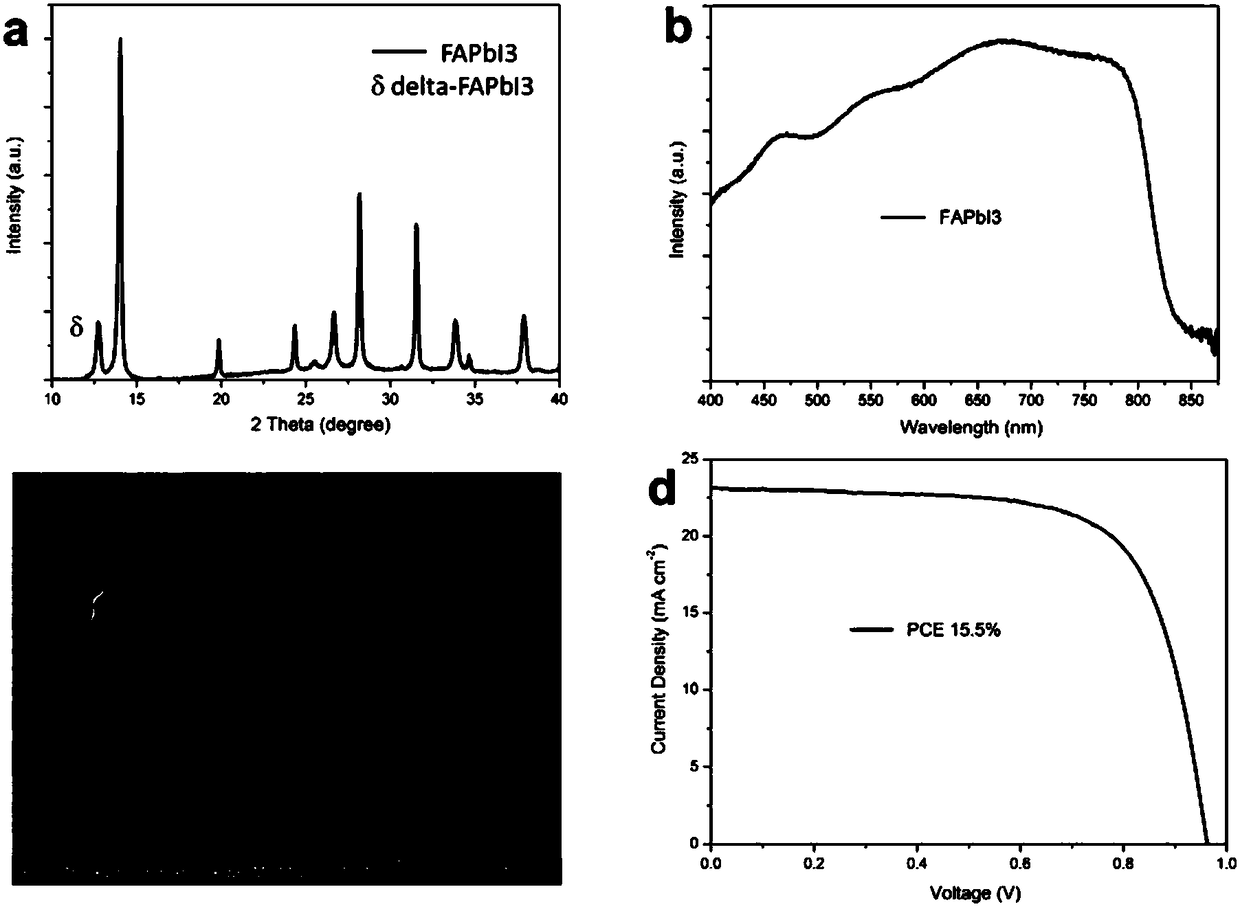

Embodiment 1

[0030] In this embodiment, first configure FAPbI 3 Precursor solution, that is, weigh FAI and PbI with the same molar mass 2 Raw materials, dissolved in a mixed solvent of DMF and NMP, FAI and PbI 2 The molar concentration is 1.6M, the volume ratio of DMF and NMP in the mixed solvent is 1:1, and stirred at room temperature for 12h to form a uniform, stable and transparent solution. Afterwards, 0.1 mL of the above-mentioned FAPbI 3 The precursor solution was dropped onto the surface covered with TiO 2 On the conductive glass substrate of the nanocrystalline film, stand still for 5s, start the spin coating machine, the acceleration of the spin coating machine is 1000rpm, the rotation speed is 5000rpm, and the spin coating time is 25s. After the spin coater reached 5000 rpm for 5 seconds, the surface of the rotating substrate was quickly rinsed with 5 mL of ether at one time. After the spin-coating process, the substrate was placed on a hot plate furnace, the temperature of t...

Embodiment 2

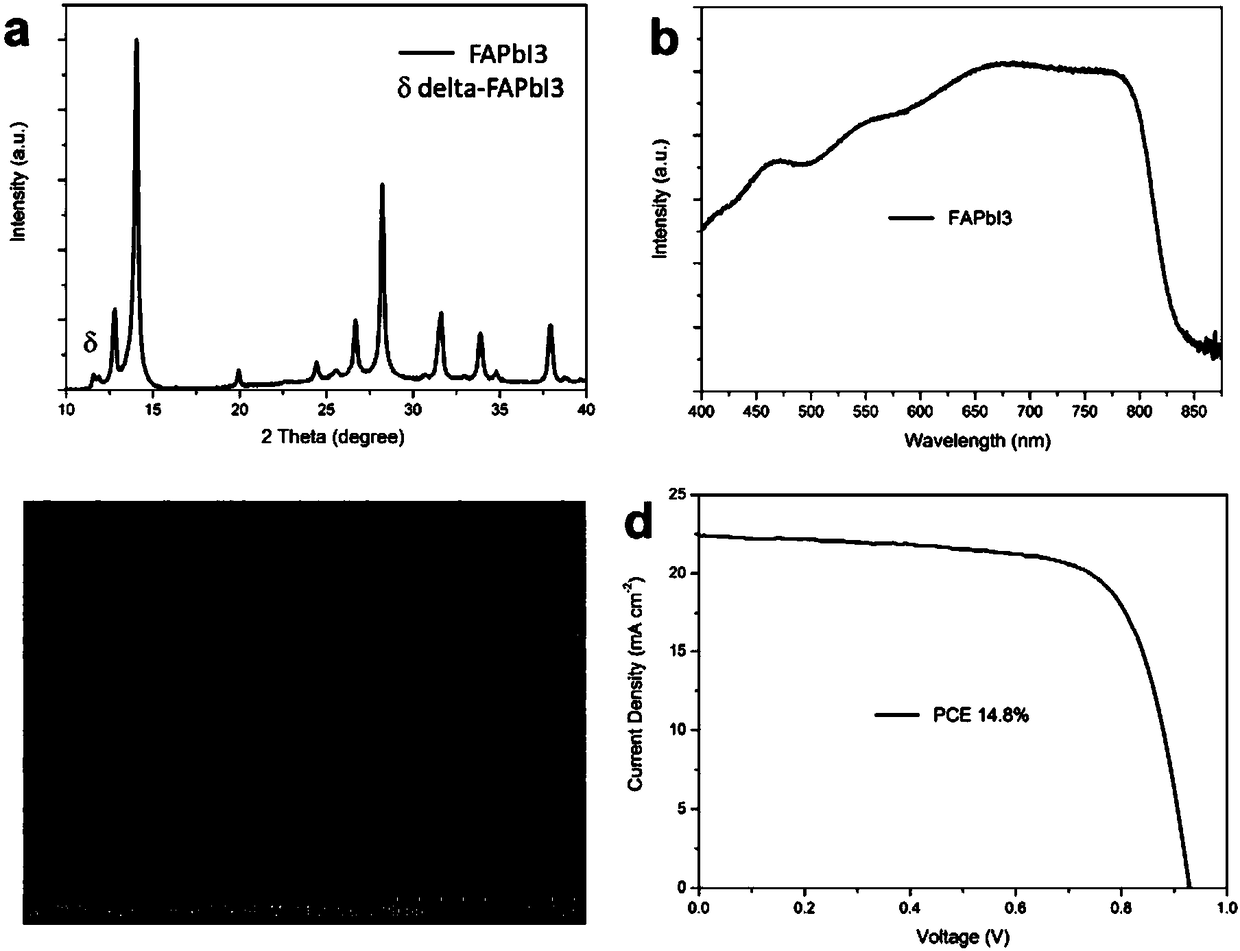

[0034] In this embodiment, first configure FAPbI 3 Precursor solution, that is, weigh FAI and PbI with the same molar mass 2 Raw materials, dissolved in a mixed solvent of DMF and NMP, FAI and PbI 2 The molar concentration is 1.6M, the volume ratio of DMF and NMP in the mixed solvent is 4:1, and stirred at room temperature for 12h to form a uniform, stable and transparent solution. Afterwards, 0.2 mL of the above-mentioned FAPbI 3 The precursor solution was dropped onto the surface covered with TiO 2 On the conductive glass substrate of the nanocrystalline film, stand still for 5s, start the spin coating machine, the acceleration of the spin coating machine is 1000rpm, the rotation speed is 5000rpm, and the spin coating time is 25s. After the spin coater reached 5000 rpm for 5 seconds, the surface of the rotating substrate was quickly rinsed with 5 mL of ether at one time. After the spin-coating process, the substrate was placed on a hot plate furnace, the temperature of t...

Embodiment 3

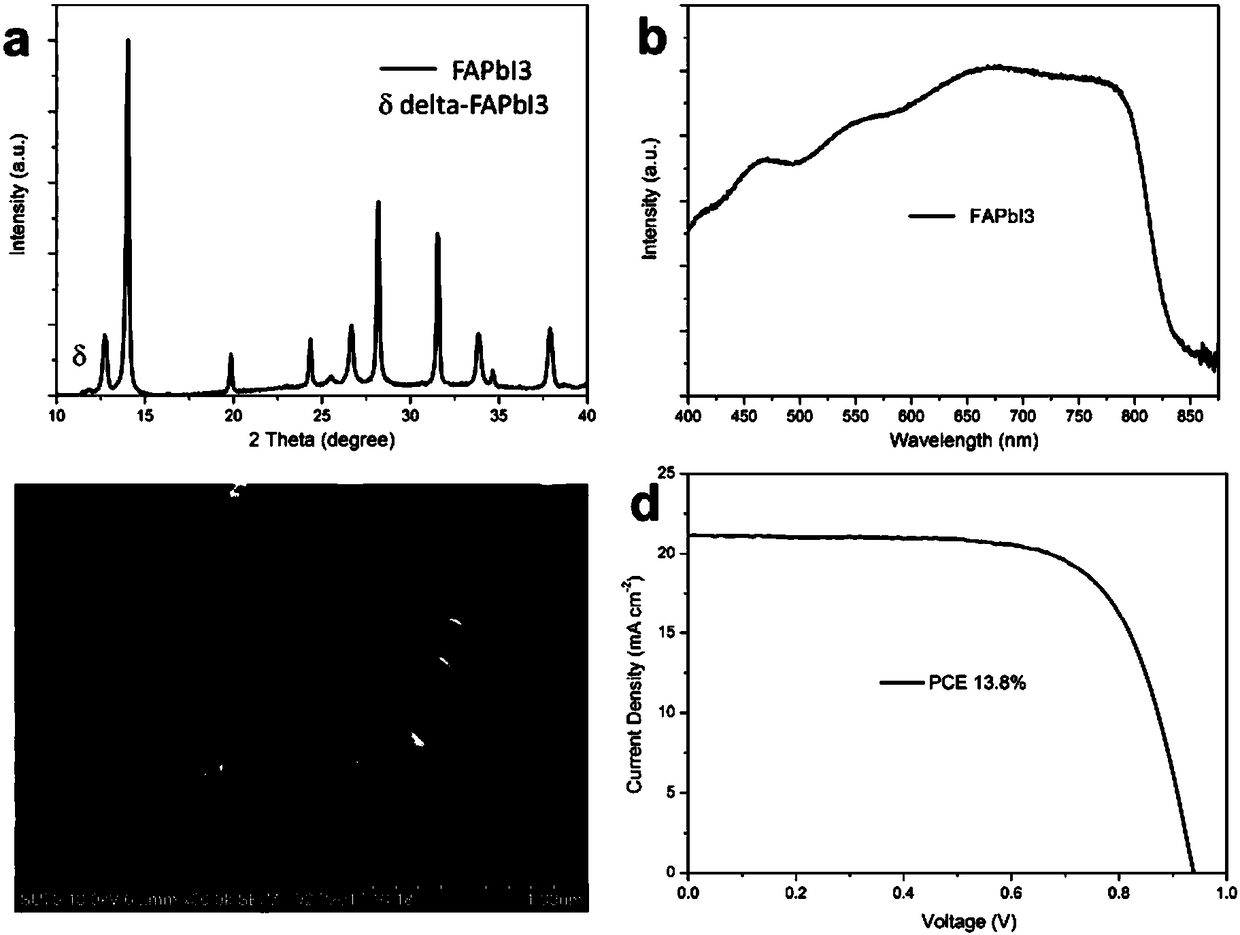

[0038] In this embodiment, first configure FAPbI 3 Precursor solution, that is, weigh FAI and PbI with the same molar mass 2 Raw materials, dissolved in a mixed solvent of DMF and NMP, FAI and PbI 2 The molar concentration is 1.2M, the volume ratio of DMF and NMP in the mixed solvent is 1:1, and stirred at room temperature for 12h to form a uniform, stable and transparent solution. Afterwards, 0.2 mL of the above-mentioned FAPbI 3 The precursor solution was dropped onto the surface covered with TiO 2 On the conductive glass substrate of the nanocrystalline film, stand still for 5s, start the spin coating machine, the acceleration of the spin coating machine is 4000rpm, the rotation speed is 4000rpm, and the spin coating time is 40s. After the spin coater reached 4000 rpm for 5 seconds, the surface of the rotating substrate was quickly rinsed with 5 mL of ether at one time. After the spin-coating process, the substrate was placed on the hot plate furnace, the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com