Grinding wheel automatic dismounting machine containing Teflon sheet and dismounting technology thereof

A technology of Teflon sheet and grinding wheel, which is applied in the field of automatic disassembly and assembly of grinding wheel and its disassembly process, can solve the problems of unable to meet the production efficiency of enterprises, time-consuming and labor-intensive, etc., achieve high equipment automation, reduce labor intensity, Ingenious effect of craft design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

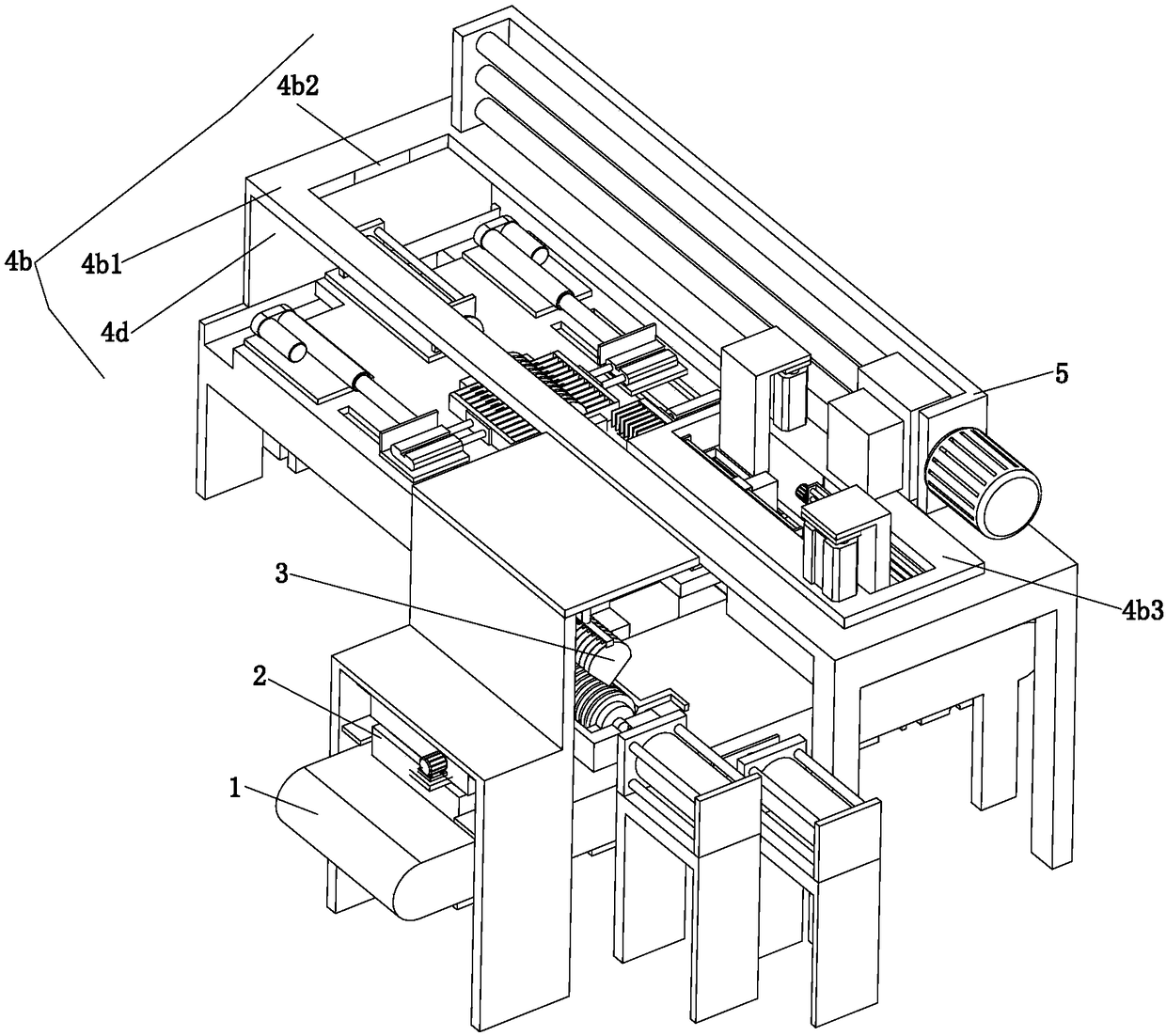

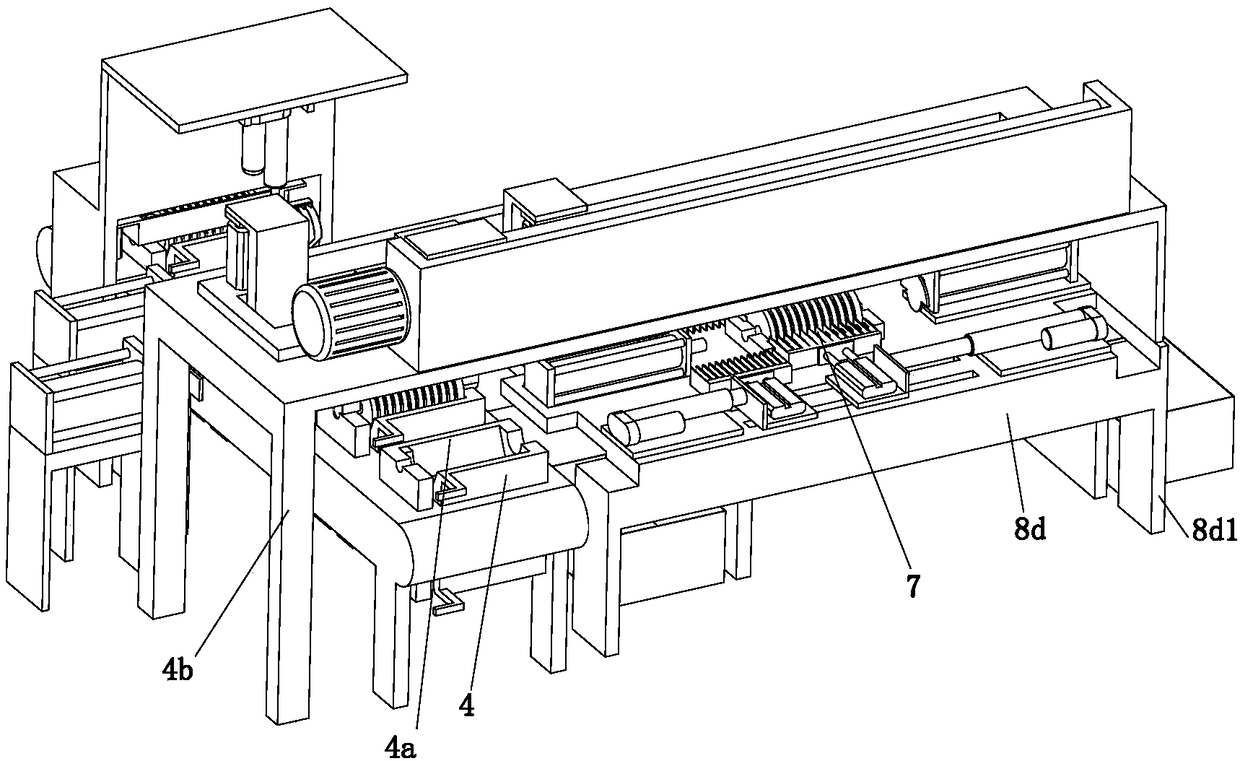

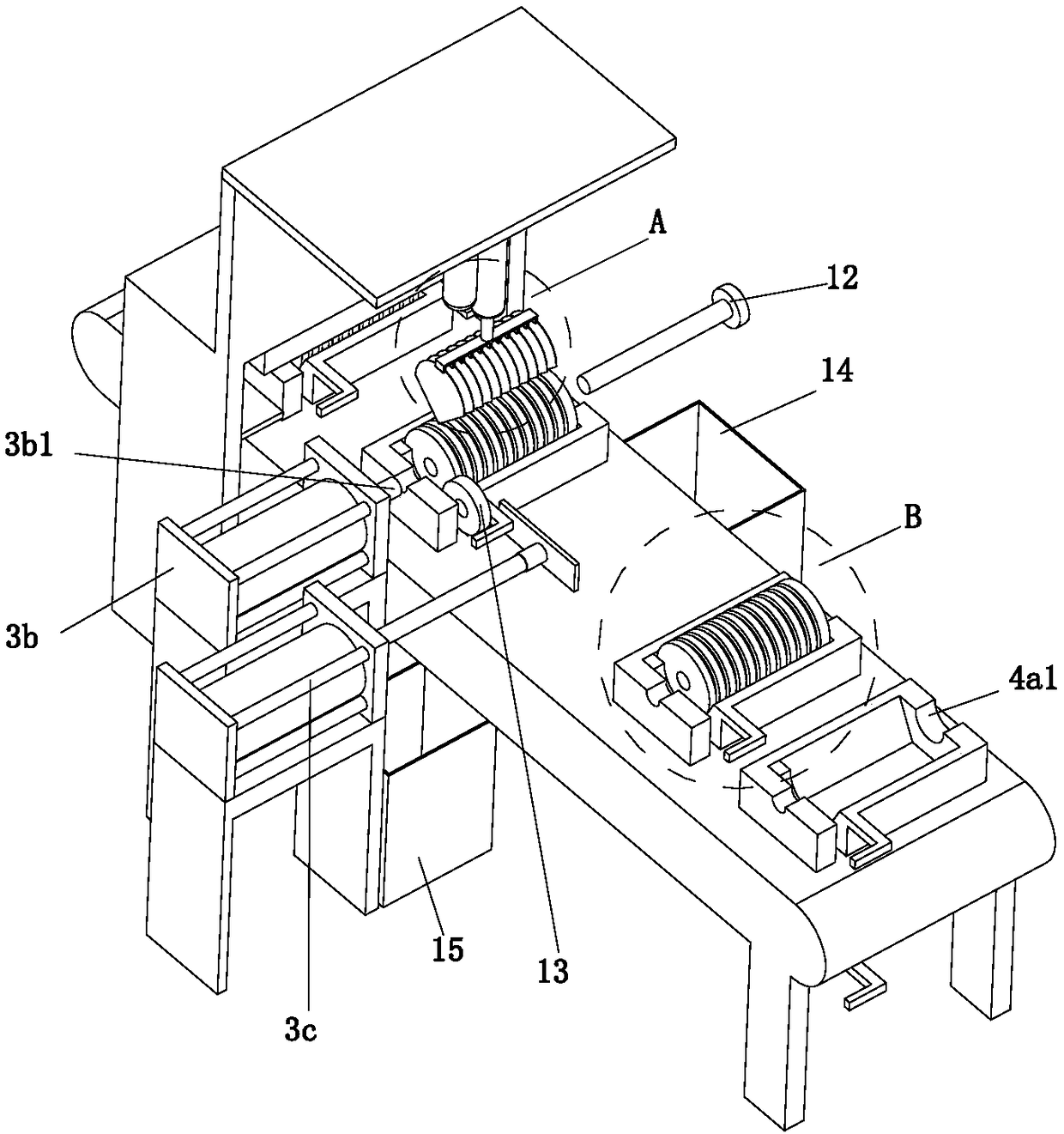

[0044] refer to Figure 1 to Figure 22 The shown automatic removal and assembly machine for grinding wheel discs containing Teflon sheets includes a stepping conveyor belt 1, an automatic removal mechanism and a two-stage separation mechanism. The automatic removal mechanism includes a friction part 2 that rubs against the Teflon sheet 9 to make it loose And the shoveling part 3 that is used to peel off the Teflon sheet 9 and the emery wheel sheet 11, the friction part 2 and the shoveling part 3 are all positioned at the top of the stepping conveyor belt 1, the friction part 2 includes some friction round bars 2f1, and the friction round bar 2f1 Close to the feeding end of the stepping conveyor belt 1, the two-stage separation mechanism is located at the discharging end of the stepping conveyor belt 1, and the shoveling part 3 includes a plurality of shoveling thin plates 3a3, and the shoveling thin plates 3a3 are arranged near the middle section of the stepping conveyor belt 1...

Embodiment 2

[0060] The dismounting process of the automatic dismounting machine of the emery wheel disc that contains the teflon sheet described in embodiment 1, comprises the following steps:

[0061] Step 1. First, manually pass the group of grinding wheel pieces 11 through the ejector pin 12 of the middle hole, and place them in the placement groove of the positioning jig 4. A first semi-arc groove 4a1 at both ends of the placement groove can support The two ends of the push rod 12 in the group of grinding wheel sheets 11 are then conveyed by the stepping conveyor belt 1. After reaching the position of the friction member 2, the friction cylinder 2d1 will work, and the friction cylinder 2d1 will drive the rectangular support box 2a to descend, so that all The middle sections of the friction round rods 2f1 are in contact with the surface above the Teflon sheet 9 one by one, and then the friction motor 2f works to drive the friction round rods 2f1 connected to it to rotate, and drives all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com