Highly conglutination resistant, high temperature resistant and environment-friendly water-based preprinting gloss oil and preparation method thereof

A high-temperature-resistant and sticking technology, applied in pigment-containing coatings, coatings, paper coatings, etc., can solve the problems of difficult to withstand mounting temperature and insufficient high-temperature resistance of ordinary water-based varnishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

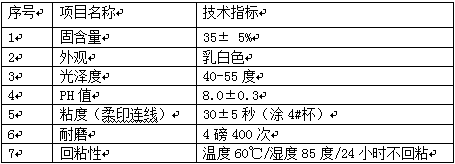

Image

Examples

Embodiment 1

[0029] ⑴Preparation of high temperature resistant water-soluble acrylate copolymer

[0030] 1.1. Raw material ratio of each component of high temperature resistant water-soluble acrylate copolymer

[0031] Mixed monomer:

[0032] Butyl acrylate (BA) 20 kg,

[0033] Norbornyl methacrylate 3 kg,

[0034] Octyl methacrylate 2 kg,

[0035] Hydroxyethyl methacrylate (HEMA) 5 kg,

[0036] Hydroxypropyl Acrylate (HPA) 10 kg,

[0037] Acrylic acid (AA) 20 kg,

[0038] Initiator: benzoyl peroxide 0.5 kg,

[0039] Neutralizer: ammonia,

[0040] Solvent: isopropanol 39.5 kg;

[0041] 1.2. Preparation of high temperature resistant water-soluble acrylate copolymer

[0042] Add isopropanol 30Kg, mixed monomer (butyl acrylate (BA) 10Kg, norbornyl methacrylate 1.5 kg, methyl Octyl acrylate 1 kg, hydroxyethyl methacrylate (HEMA) 2.5 kg, hydroxypropyl acrylate (HPA) 5 kg, acrylic acid (AA) 10 kg), 0.125kg benzoyl peroxide, start stirring and heat up to reflow. After reacting for 15 ...

Embodiment 2

[0051] ⑴Preparation of high temperature resistant water-soluble acrylate copolymer

[0052] 1.1. Raw material ratio of each component of high temperature resistant water-soluble acrylate copolymer

[0053] Mixed monomer:

[0054] Butyl acrylate (BA) 25 kg,

[0055] Norbornyl methacrylate 6 kg,

[0056] Octyl methacrylate 6 kg,

[0057] Hydroxyethyl methacrylate (HEMA) 8 kg,

[0058] Hydroxypropyl Acrylate (HPA) 12 kg,

[0059] Acrylic acid (AA) 30 kg,

[0060] Initiator: benzoyl peroxide 0.8 kg,

[0061] Neutralizer: ammonia,

[0062] Solvent: isopropanol 12.2 kg;

[0063] 1.2. Preparation of high temperature resistant water-soluble acrylate copolymer

[0064]Add isopropanol 10Kg, mixed monomer (butyl acrylate (BA) 12.5Kg, norbornyl methacrylate 3 kg, Octanol methacrylate 3kg, hydroxyethyl methacrylate (HEMA) 4kg, hydroxypropyl acrylate (HPA) 6 kg, acrylic acid (AA) 15kg), 0.2kg benzoyl peroxide, start stirring and heat up to reflux. After reacting for 15 minutes, a...

Embodiment 3

[0073] ⑴Preparation of high temperature resistant water-soluble acrylate copolymer

[0074] 1.1. Raw material ratio of each component of high temperature resistant water-soluble acrylate copolymer

[0075] Mixed monomer:

[0076] Butyl acrylate (BA) 30 kg,

[0077] Norbornyl methacrylate 10 kg,

[0078] Octyl methacrylate 10 kg,

[0079] Hydroxyethyl methacrylate (HEMA) 10 kg,

[0080] Hydroxypropyl Acrylate (HPA) 15 kg,

[0081] Acrylic acid (AA) 14 kg,

[0082] Initiator: benzoyl peroxide 1.0 kg,

[0083] Neutralizer: ammonia,

[0084] Solvent: isopropanol 10 kg;

[0085] 1.2. Preparation of high temperature resistant water-soluble acrylate copolymer

[0086] Add isopropanol 8Kg, mixed monomer (butyl acrylate (BA) 15Kg, norbornyl methacrylate 5kg, methyl Octanol acrylate 5kg, hydroxyethyl methacrylate (HEMA) 5kg, hydroxypropyl acrylate (HPA) 7.5kg, acrylic acid (AA) 7kg), 0.25kg benzoyl peroxide, start stirring and heat up to reflux. After reacting for 15 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com