Hybrid material with UV (Ultraviolet)-light induced gradient structure, preparation method and application of hybrid material in aspect of responsive shape transformation

A technology of gradient structure and hybrid materials, which is applied in the application fields of ultraviolet light-induced gradient structure hybrid materials, preparation, and responsive shape transformation. Issues such as promotion and use in a wide range to achieve a highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

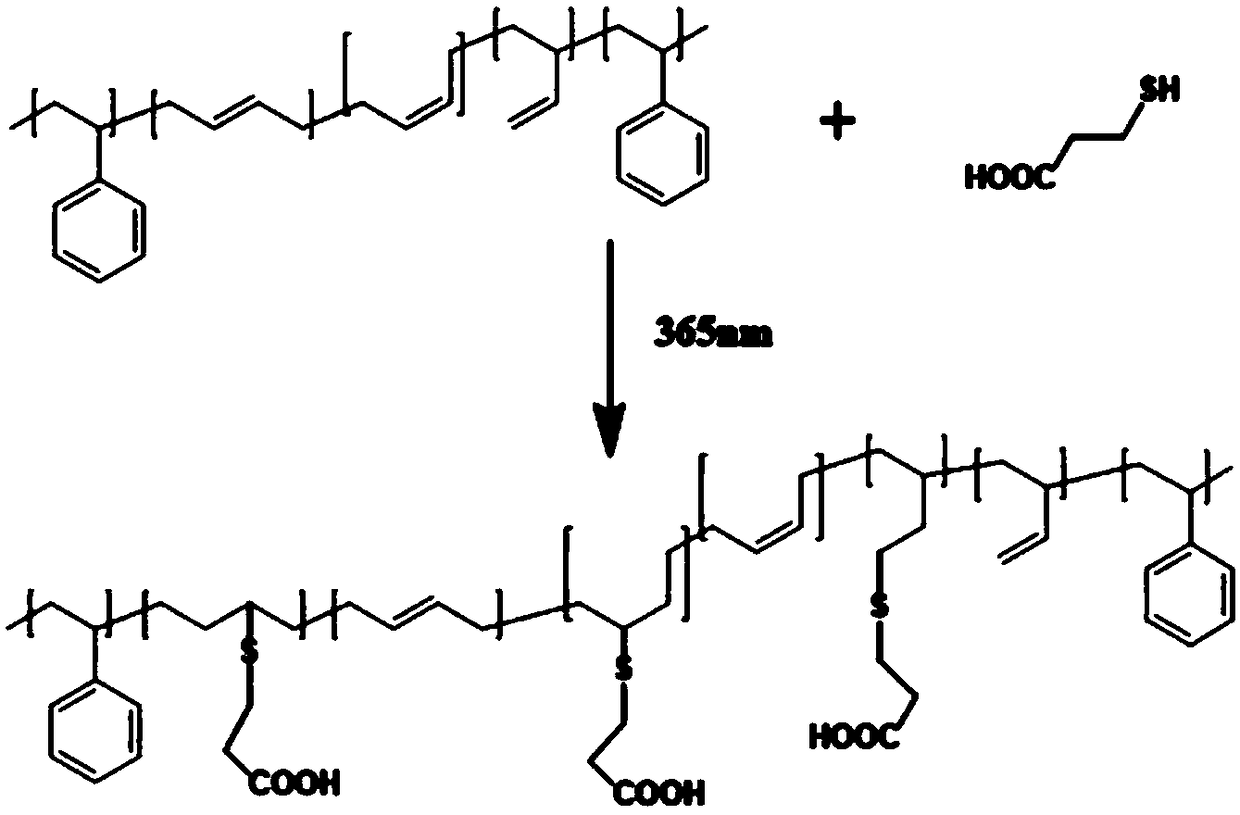

[0040] SBS and mercaptopropionic acid were dissolved in toluene in different proportions, and an appropriate amount of photoinitiator I907 was added. In this example, the proportion was set to 20%. After stirring, the click reaction was performed under ultraviolet light. figure 1 Is the reaction process equation.

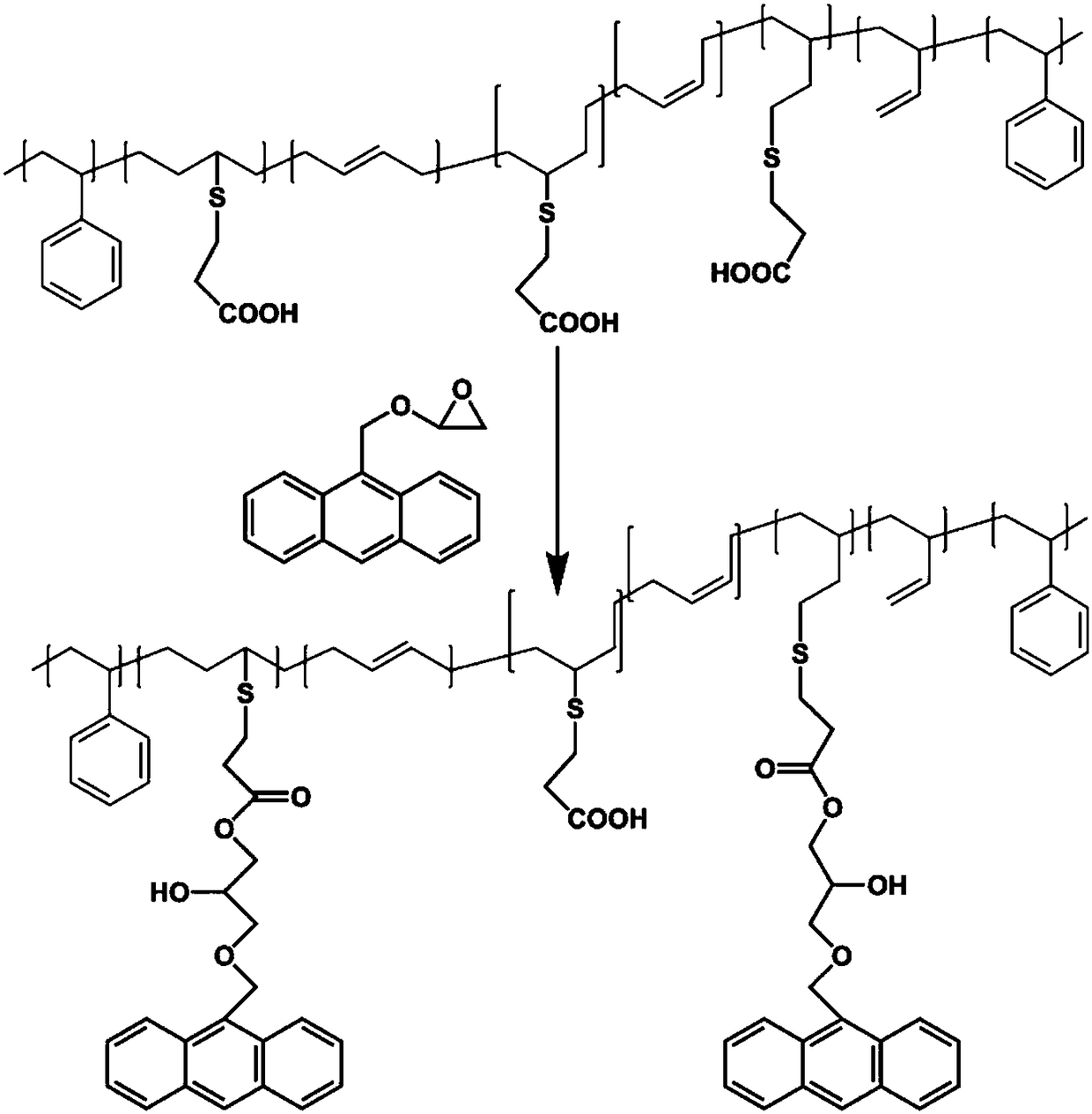

[0041] Dissolve carboxyl grafted SBS in toluene and add anthracene epoxy compound Reacted at 80°C for 48 hours to obtain anthracene grafted SBS. The grafting amount of anthracene in this embodiment is 50% of the carboxyl group. figure 2 It is the SBS reaction equation of anthracene grafting. image 3 It is the nuclear magnetic spectrum of carboxyl grafted SBS and anthracene grafted SBS in Example 1.

Embodiment 2

[0043] The SBS grafted with anthracene and carbon nanotubes (1%, 2%, 3%, 4%, 5%) in toluene were mixed uniformly in toluene and heated at 0°C. Remove the solvent to form a film. Figure 4 It is the stress-strain curve of hybrid materials with different carbon nanotube content. As the content of carbon nanotubes increases, the breaking strength and modulus of the material increase, and the breaking elongation decreases. In this system, several composite materials with carbon nanotube content have good elasticity. In order to balance the elasticity and strength properties, we select the composite material with carbon nanotube content of 2% as a representative to study its responsive deformation, but This performance is not limited to this content of composite materials.

Embodiment 3

[0045] A hybrid material with an ultraviolet light-induced gradient structure prepared by grafting a photosensitive group with an elastomer material and a carbon nanomaterial (the sample containing 2% of carbon nanotubes prepared in Example 2) was pre-stretched under heating at 80°C , Make the stretch rate be 100%, 200% and 300% respectively, and then lower to room temperature; treat with 365nm wavelength ultraviolet light for 10 minutes, then heat at 100°C for 20 minutes. The shape of the membrane changes, such as Figure 5 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com