A kind of preparation method of carbon airgel thermal insulation composite material

A composite material, carbon aerogel technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of further improvement of thermal insulation performance, high production cost, strict drying process, etc., to achieve high strength, Good formability and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

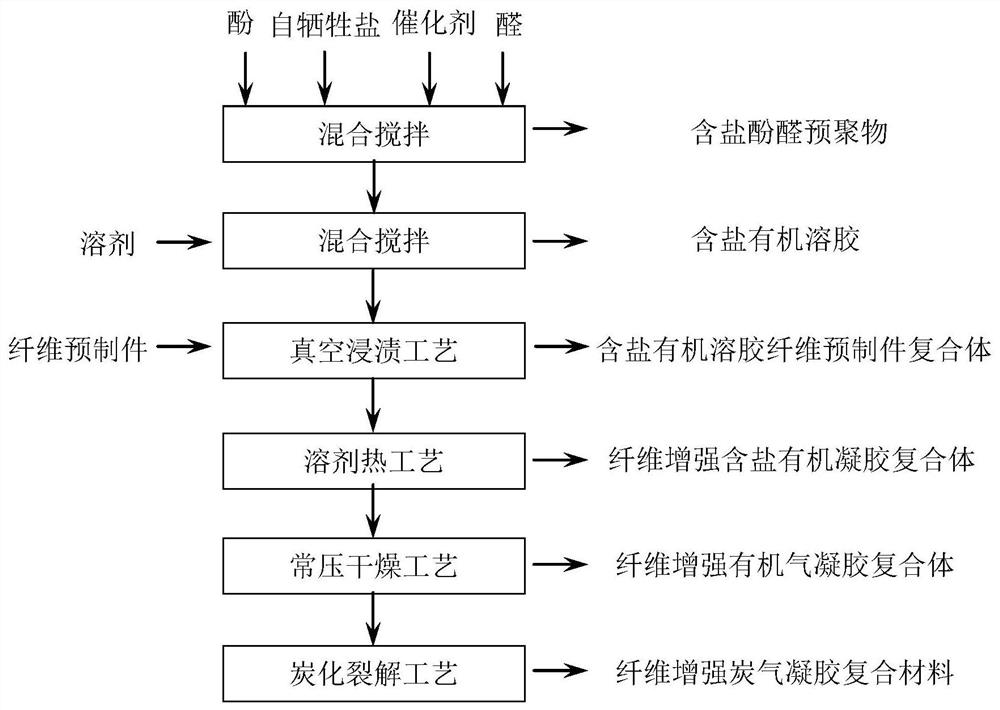

Method used

Image

Examples

Embodiment 1

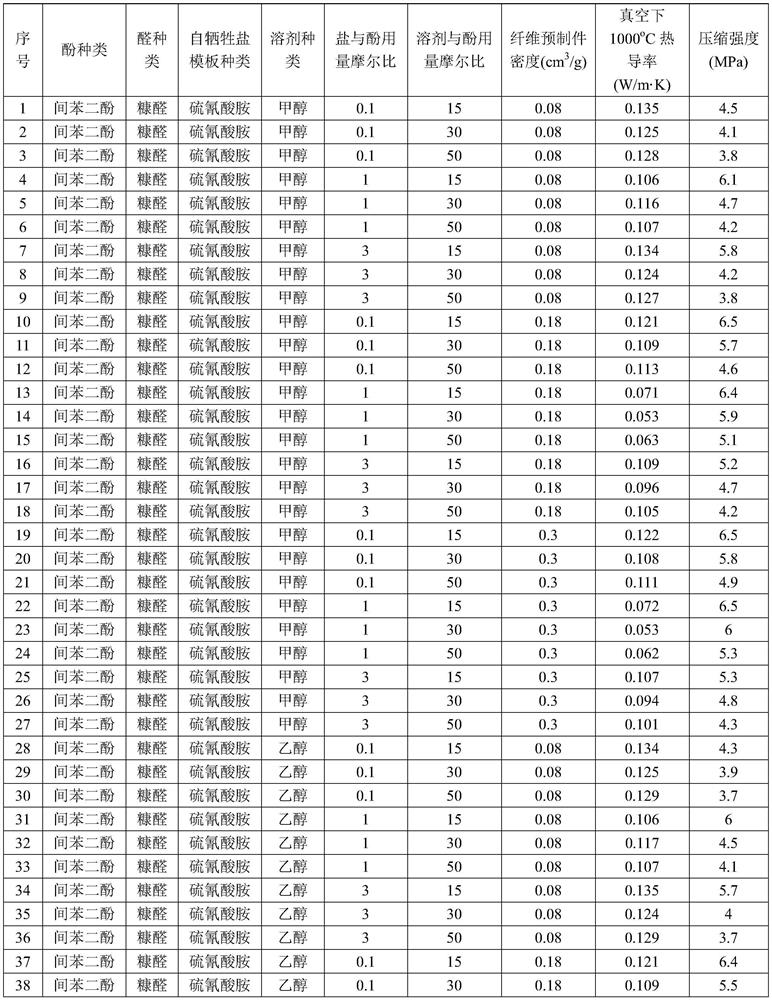

[0042] (1) Preparation of salt-containing organosol: use resorcinol organic monomer and furfural organic monomer as carbon precursors, ammonium thiocyanate as self-sacrificing salt template, methanol as solvent, and basic catalyst hexamethylene The specific process is as follows: firstly, resorcinol, furfural organic monomer, ammonium thiocyanate, and hexamethylenetetramine were mixed and stirred for 1 hour to obtain a salt-containing phenolic prepolymer, and then methanol was added Continue to stir until a uniform solution is formed to obtain a salt-containing organosol, wherein the mol ratio of the five raw materials is furfural: resorcinol=2, ammonium thiocyanate: resorcinol=1, methyl alcohol: phenol=30, Hexamethylenetetramine: Resorcinol=0.01;

[0043] (2) Preparation of salt-containing organosol fiber preform composite by vacuum impregnation process: according to the volume size of the polyacrylonitrile-based fiber preform and the apparent density of the polyacrylonitrile...

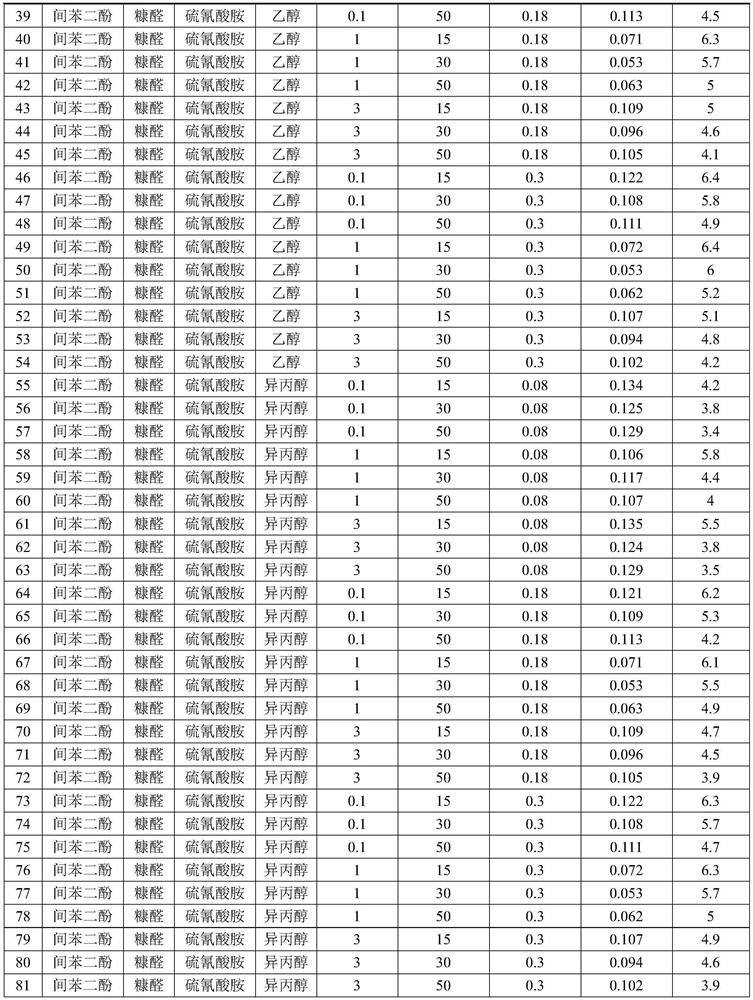

Embodiment 2~972

[0048] When preparing the salt-containing organosol in the first step, the mixing and stirring time of phenolic organic monomer, aldehyde organic monomer, self-sacrificing salt template and catalyst should be 0.1-10h to ensure that the phenolic organic monomer and aldehyde organic monomer fully react to form the phenolic preform For polymers, the amount of different catalysts depends on the type of catalyst. Different catalysts have different amounts of catalysts due to differences in their catalytic activity. Using different catalysts should ensure that phenolic organic monomers and aldehyde organic monomers fully react after mixing and stirring for 0.1-10h Form a phenolic prepolymer, so the type of catalyst and mixing time have little effect on the properties of the prepared fiber-reinforced carbon airgel composite; , the types of fibers used are all carbon precursor fibers, which will be carbonized and cracked to form carbon fibers in the fifth step of carbonization and crac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com