Method for uniformly fluorinating zinc oxide powder

A technology of zinc oxide and zinc oxide powder, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of complex process and expensive modifier, achieve strong bonding, improve surface properties, improve The effect of interface interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

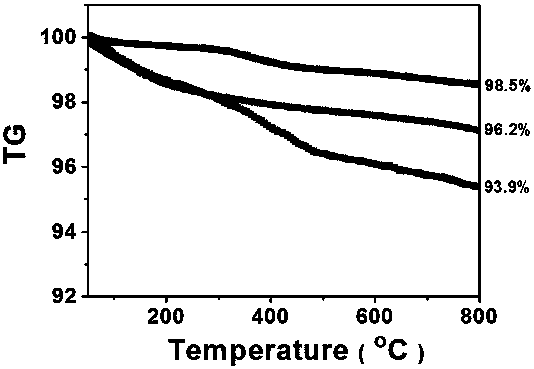

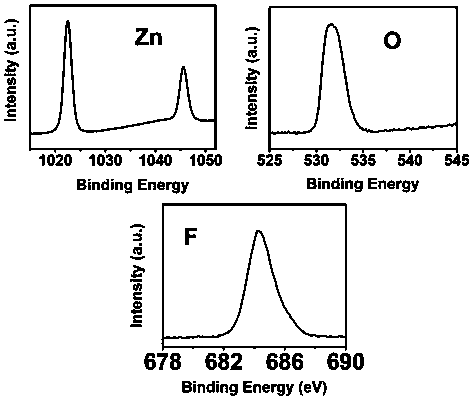

Image

Examples

Embodiment 1

[0022] A method for uniformly fluorinating zinc oxide powder, the following steps are adopted:

[0023] (1) Zinc oxide powder surface coupling agent treatment: Add zinc oxide powder with a particle size of 10nm to the mixture of titanate coupling agent NDZ-101 and alcohol, in which titanate coupling agent NDZ-101 The mass ratio of alcohol to alcohol is 1:10, treated at 90°C for 5 hours, cleaned with deionized water and alcohol, and dried in a drying oven for 2 hours;

[0024] (2) Polyvinyl alcohol coating treatment on the surface of zinc oxide powder: place the zinc oxide powder treated in the first step in polyvinyl alcohol aqueous solution, where the concentration of polyvinyl alcohol aqueous solution is 5%, zinc oxide powder and The mass ratio of the polyvinyl alcohol aqueous solution is 1:1, stirred at 50°C for 5 hours, then centrifuged, then centrifuged, and deionized water to wash to obtain fluorinated zinc oxide powder coated with polyvinyl alcohol on the surface;

[0...

Embodiment 2

[0029] A method for uniformly fluorinating zinc oxide powder, the following steps are adopted:

[0030] (1) Zinc oxide powder surface coupling agent treatment: Add zinc oxide powder with a particle size of 20 μm to the mixture of titanate coupling agent NDZ-101 and alcohol, in which titanate coupling agent NDZ-101 The mass ratio of alcohol to alcohol is 1:15, treated at 100°C for 3 hours, cleaned with deionized water and alcohol, and dried in a drying oven for 2 hours;

[0031] (2) Polyvinyl alcohol coating treatment on the surface of zinc oxide powder: place the zinc oxide powder treated in the first step in a polyvinyl alcohol aqueous solution, where the concentration range of the polyvinyl alcohol aqueous solution is 20%, and the zinc oxide powder The mass ratio of polyvinyl alcohol to aqueous solution is 1:5, stirred at 80°C for 1 hour, then centrifuged, then washed with deionized water to obtain fluorinated zinc oxide powder coated with polyvinyl alcohol on the surface ;...

Embodiment 3

[0034] The method is the same as in Example 2, except that zinc oxide powder with a particle size of 5 μm is used to obtain zinc oxide powder with surface fluorination treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com