A road repair construction technology

A construction technology and road repair technology, applied in road repair, road, road and other directions, can solve the problems of increased load, sag, slowness, etc., and achieve the effect of improving the pressure bearing capacity and reducing the probability of sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

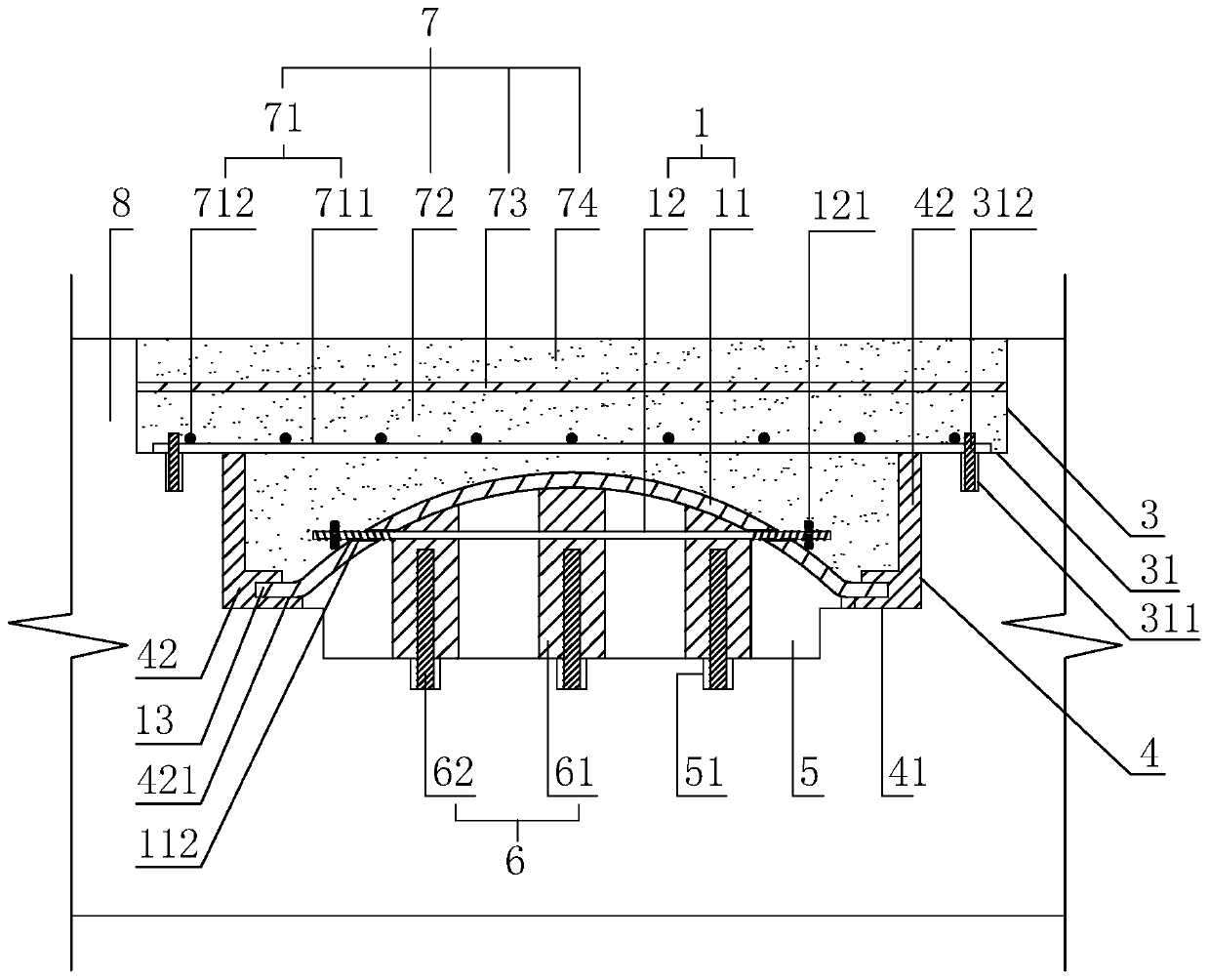

[0038] Embodiment 1: a kind of road patching construction technology, as figure 1 shown, including the following steps:

[0039] S1, open the working chamber:

[0040] S1-1, cut the reinforcement groove 3, and cut down the damaged position of the original road 8 to form the reinforcement groove 3 in the shape of a cuboid.

[0041] S1-2, cutting the construction groove 4, cutting down the groove bottom of the reinforcement groove 3 to form a cuboid-shaped construction groove 4, and the construction groove 4 and the reinforcement groove 3 are arranged coaxially. A shelving portion 31 is formed between the notch of the construction groove 4 and the bottom of the reinforcement groove 3 , and the shelving portion 31 is arranged around the circumference of the construction groove 4 .

[0042]S1-3, cutting the buffer groove 5, cutting down the groove bottom of the construction groove 4 to form the buffer groove 5, so that the connection between the construction groove 4 and the buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com