High cobalt nickel-based high-temperature alloy and preparation method thereof

A technology of nickel-based superalloys and superalloys, applied in the field of superalloys, can solve the problems of inability to achieve comprehensive performance, low Co content addition, and promote the precipitation of TCP harmful phases, so as to ensure notch sensitivity, improve durability, and improve Effect of hot workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

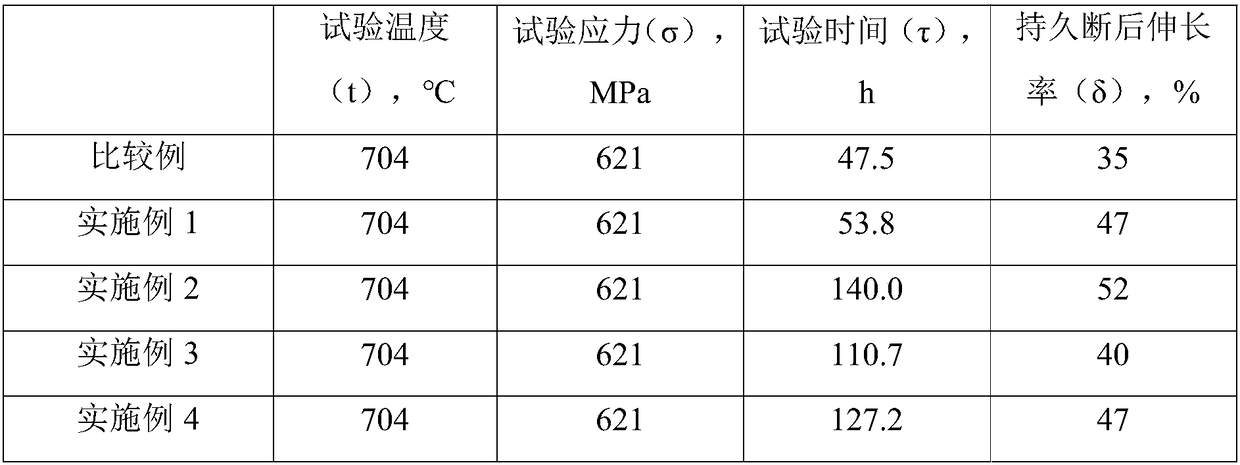

Examples

preparation example Construction

[0060] Specifically, the preparation method of the high-cobalt nickel-based superalloy may include the following steps:

[0061] Step 1: The raw material of the high-cobalt nickel-based superalloy is smelted by vacuum induction smelting and vacuum self-consumption remelting dual smelting processes to obtain alloy ingots.

[0062] Vacuum induction smelting may include the following steps: Weigh the raw materials according to the element ratio of the high-cobalt nickel-based superalloy, add the raw materials into the vacuum induction furnace, and undergo full melting, refining, and impurity removal treatments under vacuum conditions, and then tap the steel to form an alloy Ingots, where the vacuum degree of complete melting is 20Pa~30Pa, the temperature of complete melting is 1510℃~1560℃, the vacuum degree of refining is less than 5Pa, the refining temperature is 1510℃~1560℃, the refining time is more than 100min, and the tapping temperature is 1460℃ ℃~1490℃.

[0063] Vacuum co...

Embodiment 1

[0069] This embodiment provides a nickel-based superalloy for 650°C to 750°C, which includes: carbon: 0.022%, chromium: 17.89%, molybdenum: 2.73%, tungsten: 1.01%, cobalt: 12.0%, iron : 9.62%, niobium: 5.43%, aluminum: 1.63%, titanium: 0.77%, phosphorus: 0.0098%, boron: 0.0043%, and the balance is nickel.

[0070] The preparation method of this alloy is as follows:

[0071] (1) Smelting: Vacuum induction melting and vacuum self-consumption remelting dual smelting processes are adopted, specifically:

[0072]Vacuum induction smelting: Weigh a certain amount of smelting raw materials that can obtain carbon, chromium, molybdenum, tungsten, cobalt, iron, niobium, aluminum, titanium, phosphorus, boron and nickel elements according to the element ratio principle of nickel-based superalloy. The smelting raw materials are put into the vacuum induction furnace, and cast into alloy ingots after full melting, refining, and impurity removal under vacuum conditions; the full melting vacuu...

Embodiment 2

[0077] This embodiment provides a nickel-based superalloy for 650°C to 750°C, which includes: carbon: 0.023%, chromium: 17.88%, molybdenum: 2.78%, tungsten: 1.02%, cobalt: 15.0%, iron : 9.74%, niobium: 5.46%, aluminum: 1.58%, titanium: 0.76%, phosphorus: 0.0097%, boron: 0.0041%, and the balance is nickel.

[0078] The preparation method of this alloy is as follows:

[0079] (1) Smelting: Vacuum induction melting and vacuum self-consumption remelting dual smelting processes are adopted, specifically:

[0080] Vacuum induction smelting: Weigh a certain amount of smelting raw materials that can obtain carbon, chromium, molybdenum, tungsten, cobalt, iron, niobium, aluminum, titanium, phosphorus, boron and nickel elements according to the element ratio principle of nickel-based superalloy. The smelting raw materials are put into a vacuum induction furnace, and cast into alloy ingots after undergoing full melting, refining, and impurity removal treatments under vacuum conditions; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com