Preparation method of paraffin-based phase change nanoemulsion

A nanoemulsion, paraffin-based technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of phase separation and poor stability, and achieve friendly properties, high stability, and low production energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of a kind of paraffin-based phase-change nanoemulsion of the present invention comprises the following steps:

[0024] S1. Configure 10-50 parts by weight of paraffin phase change material, and then add 1-20 parts by weight of the first surfactant and no more than 5 parts by weight of co-surfactant as the first mixed solvent;

[0025] S2. Configure 25-85 parts by weight of deionized water or distilled water, and then add 1-20 parts by weight of a second surfactant as a second mixed solvent;

[0026] S3. At a temperature higher than the melting point of the paraffin phase change material but lower than 90° C. (emulsification temperature), respectively stir the first mixed solvent and the second mixed solvent to fully mix or dissolve;

[0027] S4. At the emulsification temperature in step S3, stir the first mixed solvent at a speed of 400-800 rpm, and at the same time slowly drop the second mixed solvent into the first mixed solvent to form a third ...

example 1

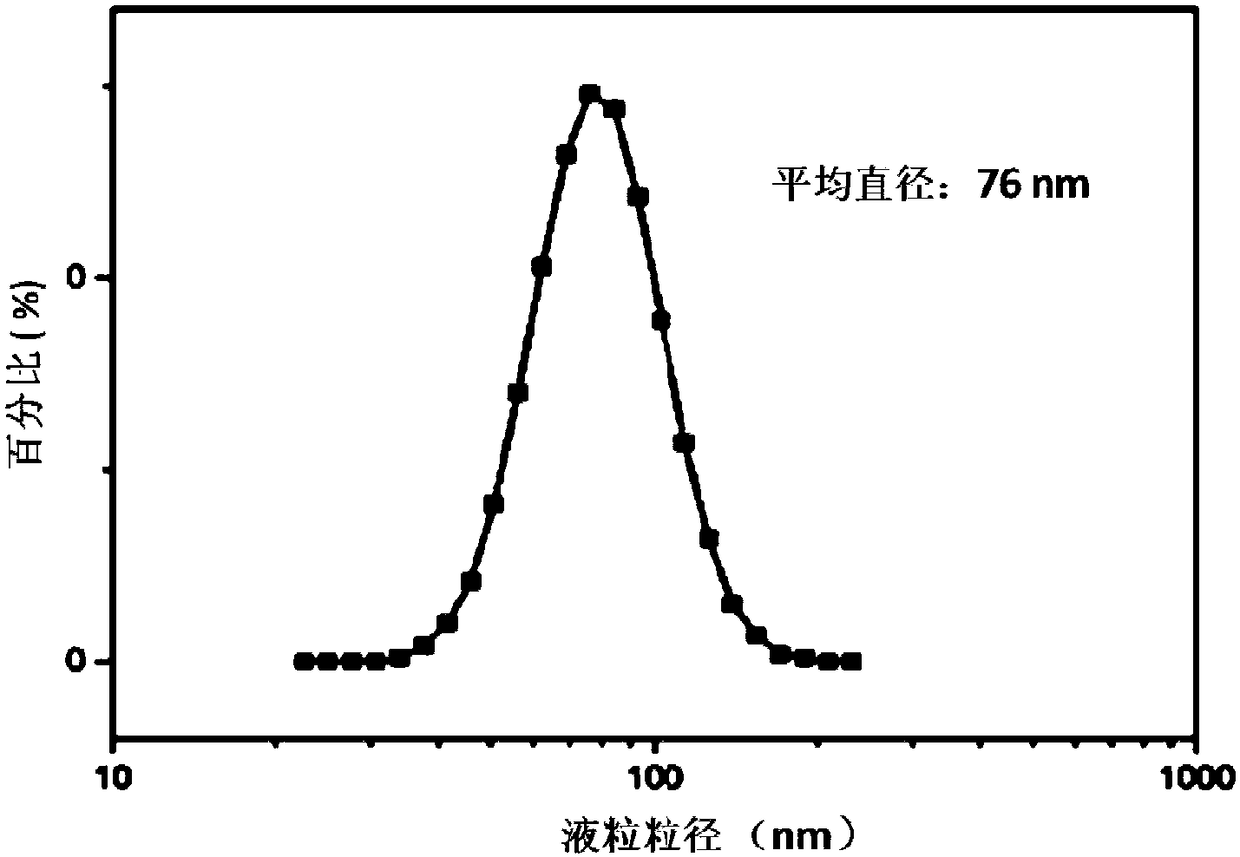

[0036] Weigh 9g of n-hexadecane, add 0.8g of Span 80, 3g of Brij L4, and 0.4g of n-butanol as the first mixed solvent. Weigh 16g of deionized water or distilled water, and add 0.8g of Tween 80 as the second mixed solvent. The above-mentioned first mixed solvent and second mixed solvent are fully mixed or dissolved respectively. Stir the first mixed solvent at 400rpm at a temperature of 70°C, and at the same time slowly drop the second mixed solvent into the first mixed solvent to obtain the third mixed solvent, and finally cool the third mixed solvent to 25°C to obtain the mass A phase change nanoemulsion with a fraction of 30% and a phase transition temperature of 17°C.

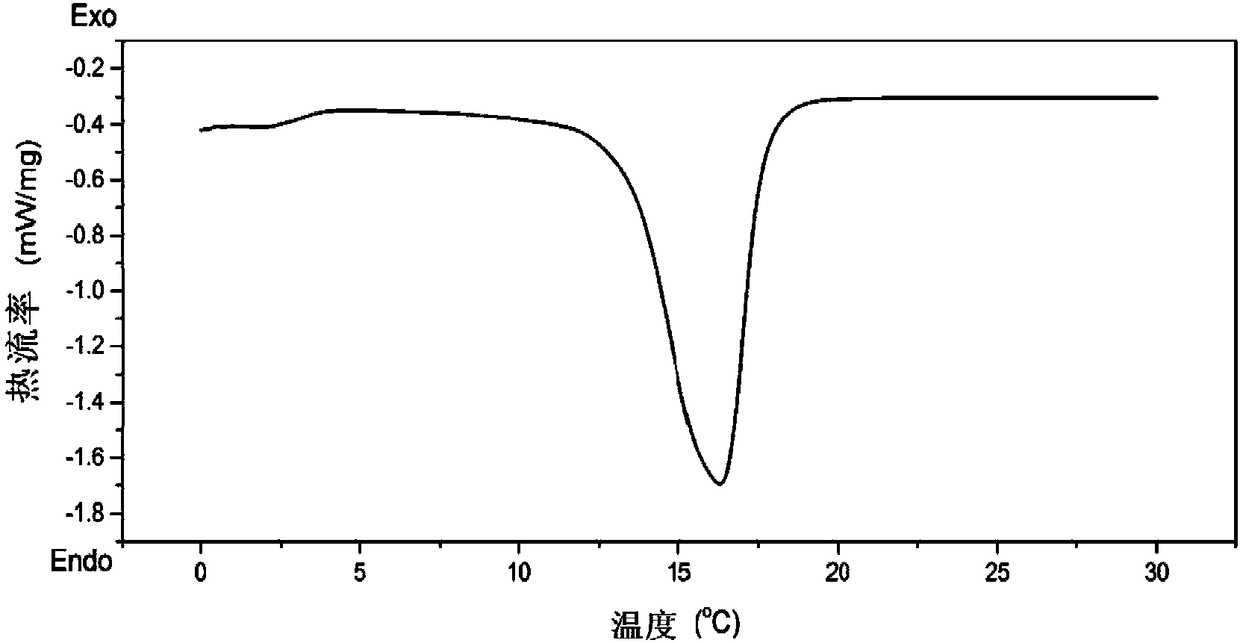

[0037] figure 1 It is a schematic diagram of the DSC curve of the phase-change nanoemulsion with a phase-change temperature of 16°C prepared in Example 1 using the preparation method of the present invention. The mass content of the paraffin phase change material is 30%, and the enthalpy change during the...

example 2

[0040] Weigh 18g of n-tetradecane, add 4.5g of Span 80 and 1g of n-butanol as the first mixed solvent. Weigh 35g of deionized water or distilled water, add 1.5g of Tween 80 as the second mixed solvent. The above-mentioned first mixed solvent and second mixed solvent are fully mixed or dissolved respectively. Stir the first mixed solvent at 400rpm at a temperature of 60°C, and at the same time slowly drop the second mixed solvent into the first mixed solvent to obtain the third mixed solvent, and finally cool the third mixed solvent to 0°C to obtain the mass A phase change nanoemulsion with a fraction of 30% and a phase transition temperature of 7°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com