A subcritical reaction preparation method of three atomic layer high-quality graphene materials

A high-quality, graphene technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of reaching hundreds of hours, difficult substrates, complicated processes, etc., to provide peeling force and avoid re-stacking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Mix 30g of iodine bromide and 50mg of expanded graphite evenly, vacuum seal it in a 50mL airtight glass bottle, place it in an oil bath environment at 100°C, and heat for 12h to prepare a third-order graphite intercalation compound.

[0022] (2) The graphite intercalation compound was quickly taken out from the glass bottle and filtered.

[0023] (3) Put the intercalation compound into a hydrothermal kettle with a volume of 50 mL rapidly.

[0024] (4) Add 10 mL of aqueous solution into the hydrothermal kettle, and quickly fix the hydrothermal kettle equipment.

[0025] (5) Heating the hydrothermal kettle to 180° C., keeping it for 1 hour, after the reaction is completed, take out the sample, and clean the sample to obtain graphene powder aggregates.

[0026] figure 2 A TEM image of the number of graphene layers was prepared for this example.

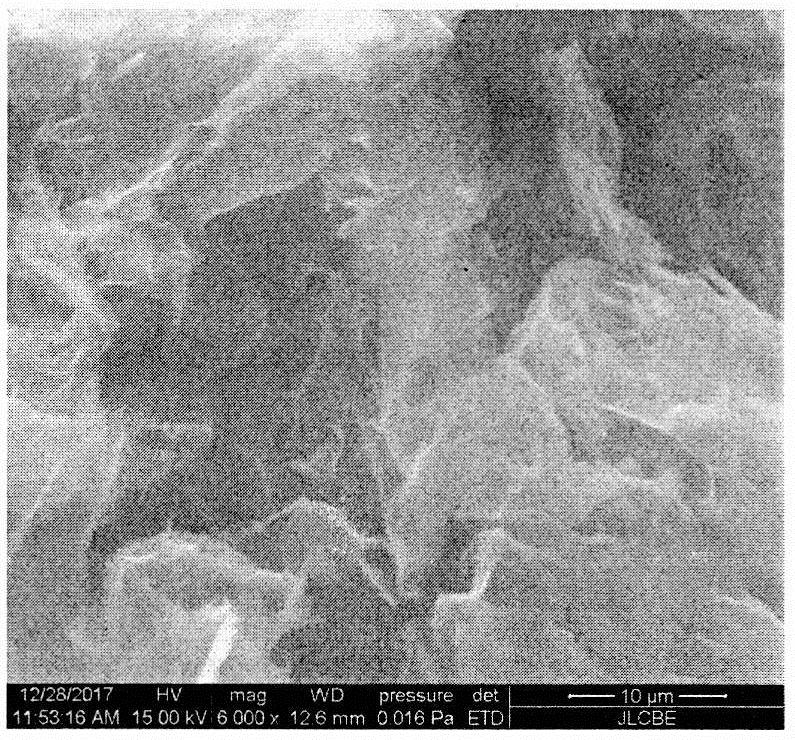

[0027] image 3 Prepare the SEM figure of graphene powder for this embodiment.

Embodiment 2

[0029] (1) Mix 30g of iodine bromide and 100mg of expanded graphite evenly, vacuum seal it in a 50mL airtight glass bottle, place it in an oil bath environment at 100°C, and heat for 24h to prepare a third-order graphite intercalation compound.

[0030] (2) The graphite intercalation compound was quickly taken out from the glass bottle and filtered.

[0031] (3) Put the intercalation compound quickly into a supercritical water device with a volume of 50 mL.

[0032] (4) Add 2 mL of aqueous solution to the supercritical water device, and quickly fix the device.

[0033] (5) Heat the hypersupercritical water device to 180° C., raise the pressure to 22.1 Mpa, and keep it for 1 hour. After the reaction is complete, take out the sample and clean the sample to obtain graphene powder aggregates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com