Bismuth molybdate photocatalyst for heavy metal wastewater treatment and preparation method

A photocatalyst, bismuth molybdate technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the unsatisfactory effect of heavy metal reduction treatment and the long-lasting effect of heavy metal sewage , poor adsorption capacity of heavy metal ions, etc., to achieve the effects of strong catalytic reduction and degradation ability, improved photocatalytic activity, and high utilization rate of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

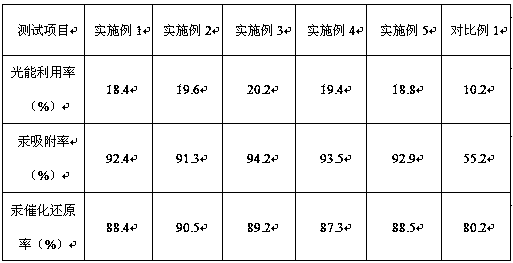

Examples

Embodiment 1

[0031] a. Add bismuth nitrate pentahydrate and ammonium heptamolybdate tetrahydrate into the reaction kettle, add ethylene glycol, ultrasonically disperse, then add dimercaptopropanol, stir magnetically for 25 minutes, add ammonia water to adjust the pH value to 9, and continue stirring 8min, prepared reaction solution;

[0032] b. Put the reaction kettle with the reaction solution in the microwave reactor to generate bismuth molybdate. After the reaction is completed, cool to room temperature, take out the mixture for centrifugation, wash with distilled water and absolute ethanol, then dry and grind , prepared dimercapto propanol modified bismuth molybdate photocatalyst.

[0033] In step a, 20 parts by weight of bismuth nitrate pentahydrate, 28 parts by weight of ammonium heptamolybdate tetrahydrate, 46 parts by weight of ethylene glycol, 5 parts by weight of dimercaptopropanol, and 1 part by weight of ammonia water.

[0034] The reactor is a carbon steel reactor.

[0035] ...

Embodiment 2

[0037]a. Add bismuth nitrate pentahydrate and ammonium heptamolybdate tetrahydrate into the reaction kettle, add ethylene glycol, ultrasonically disperse, then add dimercaptopropanol, stir magnetically for 20 minutes, add ammonia water to adjust the pH value to 8.5, and continue stirring 10min, prepared reaction solution;

[0038] b. Put the reaction kettle with the reaction solution in the microwave reactor to generate bismuth molybdate. After the reaction is completed, cool to room temperature, take out the mixture for centrifugation, wash with distilled water and absolute ethanol, then dry and grind , to prepare dimercaptopropanol modified bismuth molybdate photocatalyst.

[0039] In step a, 18 parts by weight of bismuth nitrate pentahydrate, 25 parts by weight of ammonium heptamolybdate tetrahydrate, 53 parts by weight of ethylene glycol, 3.5 parts by weight of dimercaptopropanol, and 0.5 parts by weight of ammonia water.

[0040] The reaction kettle is a stainless steel ...

Embodiment 3

[0043] a. Add bismuth nitrate pentahydrate and ammonium heptamolybdate tetrahydrate into the reaction kettle, add ethylene glycol, ultrasonically disperse, then add dimercaptopropanol, stir magnetically for 30 minutes, add ammonia water to adjust the pH value to 9.5, and continue stirring 10min, prepared reaction solution;

[0044] b. Put the reaction kettle with the reaction solution in the microwave reactor to generate bismuth molybdate. After the reaction is completed, cool to room temperature, take out the mixture for centrifugation, wash with distilled water and absolute ethanol, then dry and grind , to prepare dimercaptopropanol modified bismuth molybdate photocatalyst.

[0045] In step a, 22 parts by weight of bismuth nitrate pentahydrate, 30 parts by weight of ammonium heptamolybdate tetrahydrate, 41 parts by weight of ethylene glycol, 6 parts by weight of dimercaptopropanol, and 1 part by weight of ammonia water.

[0046] The reactor is a glass-lined reactor.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com