Preparation method of modified synthetic-zeolite heavy-metal-ion absorbing material

A heavy metal ion and synthetic zeolite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult regeneration, secondary pollution, and small adsorption capacity of heavy metal ions. Achieve the effect of increasing adsorption capacity, widening internal pores, improving adsorption capacity and regenerability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

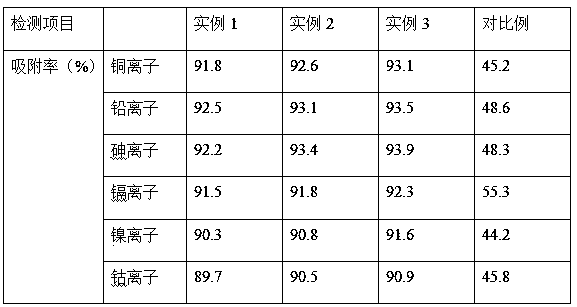

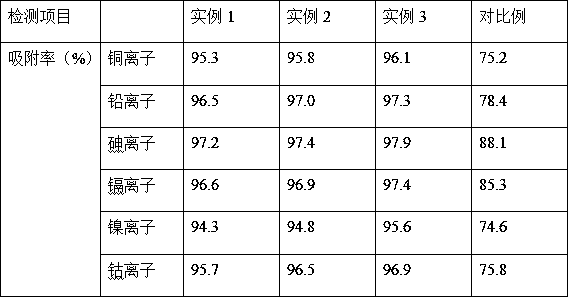

example 1

[0024] Weigh 12g of fly ash and pour it into 65mL of potassium hydroxide solution with a concentration of 8mol / L, stir and react for 4h at a temperature of 85°C to obtain the reactant, wash the reactant repeatedly with deionized water until the pH of the rinse solution is If it is neutral, the reactant after washing is placed in an oven, dried at a temperature of 95°C for 35 minutes, ground and discharged to obtain a self-made zeolite powder, and finally the self-made zeolite powder is put into a muffle furnace. Calcined at 400°C for 1 hour, cooled and discharged to obtain modified zeolite powder; mix kiwi fruit and lemon in a juicer according to the equal mass ratio and squeeze it into juice, collect the mixed juice, and then mix the modified zeolite powder, mixed juice and concentration for 10 5 The cfu / mL Acetobacter suspension is mixed in a fermenter at a mass ratio of 8:3:1, sealed and fermented at a temperature of 27°C for 7 days, and the fermentation product is taken ou...

example 2

[0026] Weigh 14g of fly ash and pour it into 70mL of potassium hydroxide solution with a concentration of 8mol / L, stir and react for 5h at a temperature of 90°C to obtain the reactant, rinse the reactant repeatedly with deionized water until the pH of the rinse solution is If it is neutral, the washed reactant is placed in an oven, dried at a temperature of 98°C for 40 minutes, ground and discharged to obtain a self-made zeolite powder, and finally the self-made zeolite powder is put into a muffle furnace. Calcined at 440°C for 1.5h, cooled and discharged to obtain modified zeolite powder; mixed kiwi fruit and lemon in a juicer according to equal mass ratio, squeezed into juice, collected mixed juice, then modified zeolite powder, mixed juice and Concentration is 10 5 The cfu / mL Acetobacter suspension is mixed in a fermenter at a mass ratio of 8:3:1, sealed and fermented at a temperature of 30°C for 8 days, and the fermentation product is taken out after the fermentation is co...

example 3

[0028] Weigh 16g of fly ash and pour it into 75mL of potassium hydroxide solution with a concentration of 8mol / L, stir and react for 6 hours at a temperature of 95°C to obtain the reactant, rinse the reactant repeatedly with deionized water until the pH of the rinse solution is If it is neutral, the reactant after washing is placed in an oven, dried at a temperature of 100°C for 45 minutes, ground and discharged to obtain a self-made zeolite powder, and finally the self-made zeolite powder is put into a muffle furnace. Calcined at 480°C for 2 hours, cooled and discharged to obtain modified zeolite powder; mix kiwi fruit and lemon in a juicer according to equal mass ratio and squeeze into juice, collect the mixed juice, and then mix the modified zeolite powder, mixed juice and concentration for 10 5 The cfu / mL Acetobacter suspension is mixed in a fermenter with a mass ratio of 8:3:1, and sealed and fermented at a temperature of 35°C for 9 days. After the fermentation, the ferme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com