Synchronous-pyrolysis iron loaded biochar preparation method

A biochar, pyrolysis technology, applied in the fields of biofuels, chemical instruments and methods, water pollutants, etc., can solve the problems of secondary pollution, increase production costs, etc., achieve rapid growth, increase adsorption capacity, and easily obtain materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

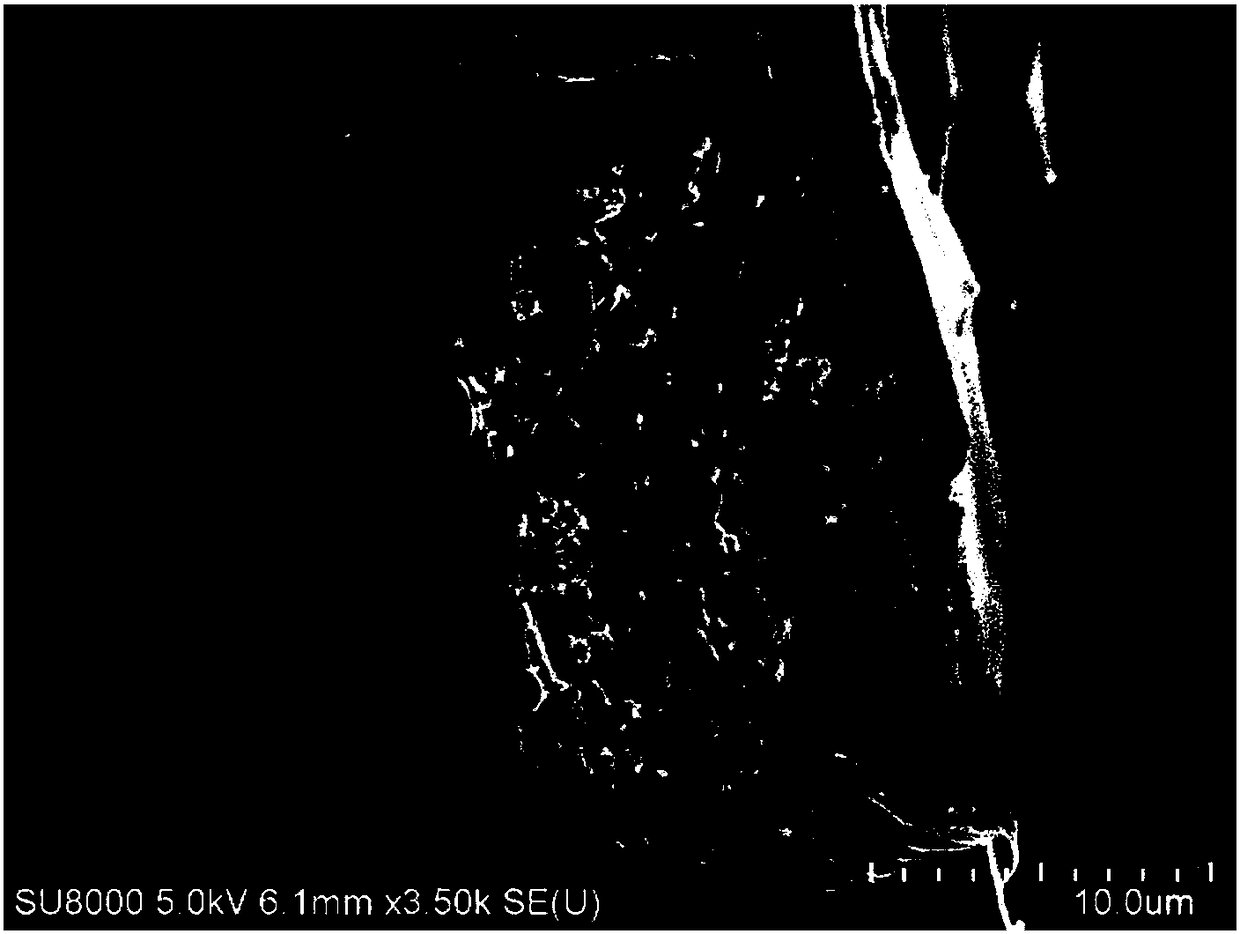

[0033] Fresh adult 4-year-old bamboo is cut into sections through a cutting machine, each section length is 1-1.5m, rinsed with water for 3 times to remove surface dust, and sieved with a nylon mesh sieve after pulverizing the bamboo to obtain 30 Purpose bamboo powder, and then put it in a ventilated and dry place for natural air-drying.

[0034] Put the bamboo powder in water and stir evenly. In the mixed solution, the ferric chloride content is 0mol / L. The negative pressure suction filtration method is used to realize solid-liquid separation, and the liquid can be reused to obtain solid bamboo powder, which is placed in The pyrolysis raw material was obtained after drying in an oven at 80°C for 24 hours.

[0035] Put the pretreated bamboo into the atmosphere tube furnace, evacuate until the vacuum degree reaches -0.1Mpa, and then pass in the inert gas N 2 , after returning to normal pressure, repeat the vacuuming and ventilation operations once, and return to normal pressur...

Embodiment 2

[0037] Fresh adult 5-year-old bamboo is cut into sections through a cutting machine, each section length is 1-1.5m, rinsed with water 3 times to remove surface dust, and sieved with a nylon mesh sieve after pulverizing the bamboo with a pulverizer to obtain 50 Purpose bamboo powder, and then put it in a ventilated and dry place for natural air-drying.

[0038] Put the bamboo powder in the ferric chloride solution and stir evenly. In the mixed solution, the ferric chloride content is 0.5mol / L. Use the suction filtration method to achieve solid-liquid separation to obtain solid bamboo powder, and put it in an oven at 80°C , and obtained the pyrolysis raw material after drying for 24 hours.

[0039] Put the pretreated bamboo into the atmosphere tube furnace, evacuate until the vacuum degree reaches -0.1Mpa, and then pass in the inert gas N 2 , after returning to normal pressure, repeat the vacuuming and ventilation operations once, and return to normal pressure again. Open the ...

Embodiment 3

[0041] Fresh adult 6-year-old bamboo is cut into sections through a cutting machine, each section length is 1-1.5m, rinsed with water 3 times to remove surface dust, and sieved with a nylon mesh sieve after pulverizing the bamboo with a pulverizer to obtain 80 Purpose bamboo powder, and then put it in a ventilated and dry place for natural air-drying.

[0042] Put the bamboo powder in the ferric chloride solution and stir evenly. In the mixed solution, the ferric chloride content is 2.0mol / L. Use the suction filtration method to achieve solid-liquid separation to obtain solid bamboo powder, and put it in an oven at 80°C , and obtained the pyrolysis raw material after drying for 24 hours.

[0043] Put the pretreated bamboo into the atmosphere tube furnace, evacuate until the vacuum degree reaches -0.1Mpa, and then pass in the inert gas N 2 , after returning to normal pressure, repeat the vacuuming and ventilation operations once, and return to normal pressure again. Open the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com