Titanium dioxide calcination exhaust gas comprehensive utilization system and exhaust gas processing method

A tail gas treatment, titanium dioxide technology, applied in gas treatment, chemical instruments and methods, waste heat treatment, etc., can solve the problems of tail gas not being effectively desulfurized and denitrified, low efficiency of heat energy utilization, complex consumption, etc., to improve heat conversion efficiency , Improve heat utilization efficiency and reduce electricity demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

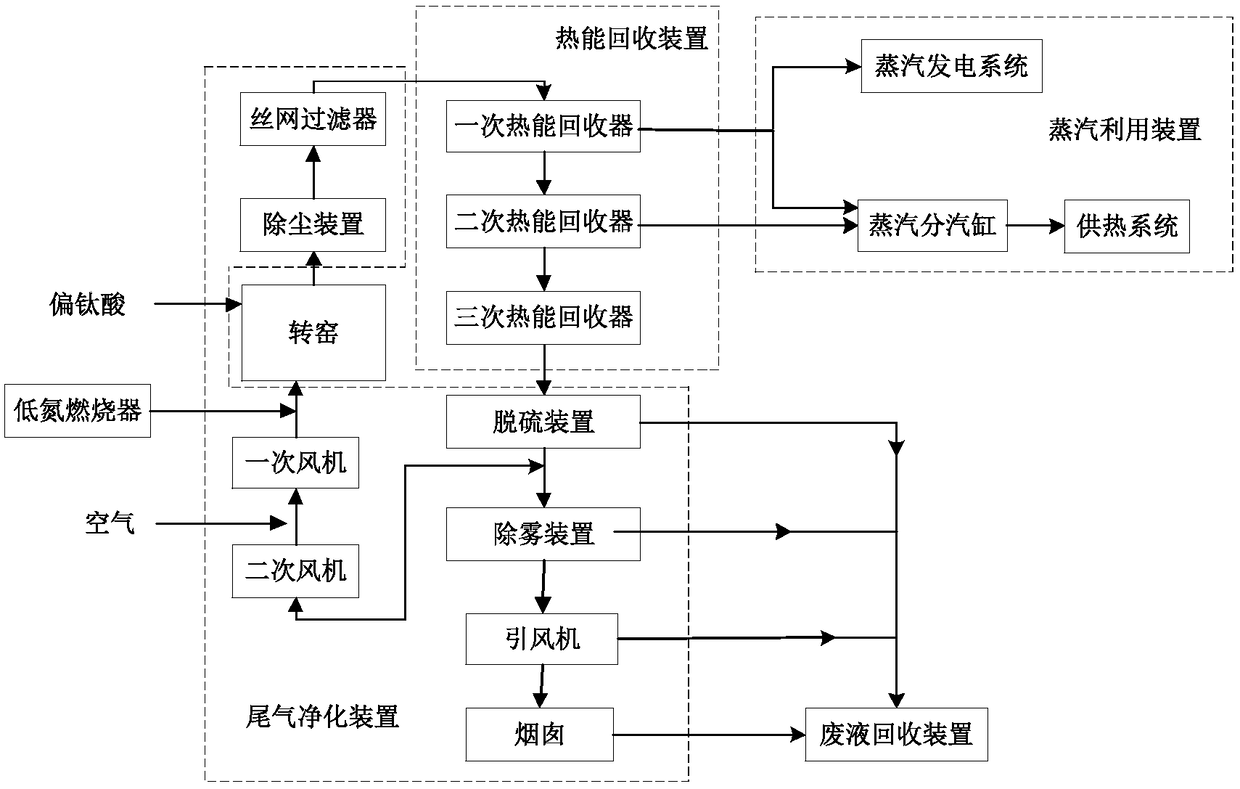

[0033] see figure 1 As shown, the embodiment of the present invention provides a comprehensive utilization system of titanium dioxide calcination tail gas, which system includes tail gas purification device, heat energy recovery device, steam utilization device and waste liquid recovery device, tail gas purification device, titanium dioxide calcination rotary kiln and thermal energy The recovery device is connected in circulation, the heat energy recovery device is connected with the steam utilization device, and the waste liquid recovery device is connected with the tail gas purification device. The circulation connection mentioned here refers to the exhaust gas purification device, the titanium dioxide calcining rotary kiln and the heat energy recovery device forming a flue gas channel connected end to end in sequence, and the gas in the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com