Solvent-free internal drag reducing coating and preparation method thereof

A solvent-free, coating technology, applied in anti-corrosion coatings, fire-retardant coatings, epoxy resin coatings, etc., can solve the problem of not being able to meet the requirements of thin coating, flexibility and short-term heat resistance, and salt spray resistance of internal drag reduction coatings at the same time. It has high requirements on salt water immersion performance, poor flexibility and heat resistance, etc., to achieve good salt spray resistance, good salt water immersion performance, and no need for special equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

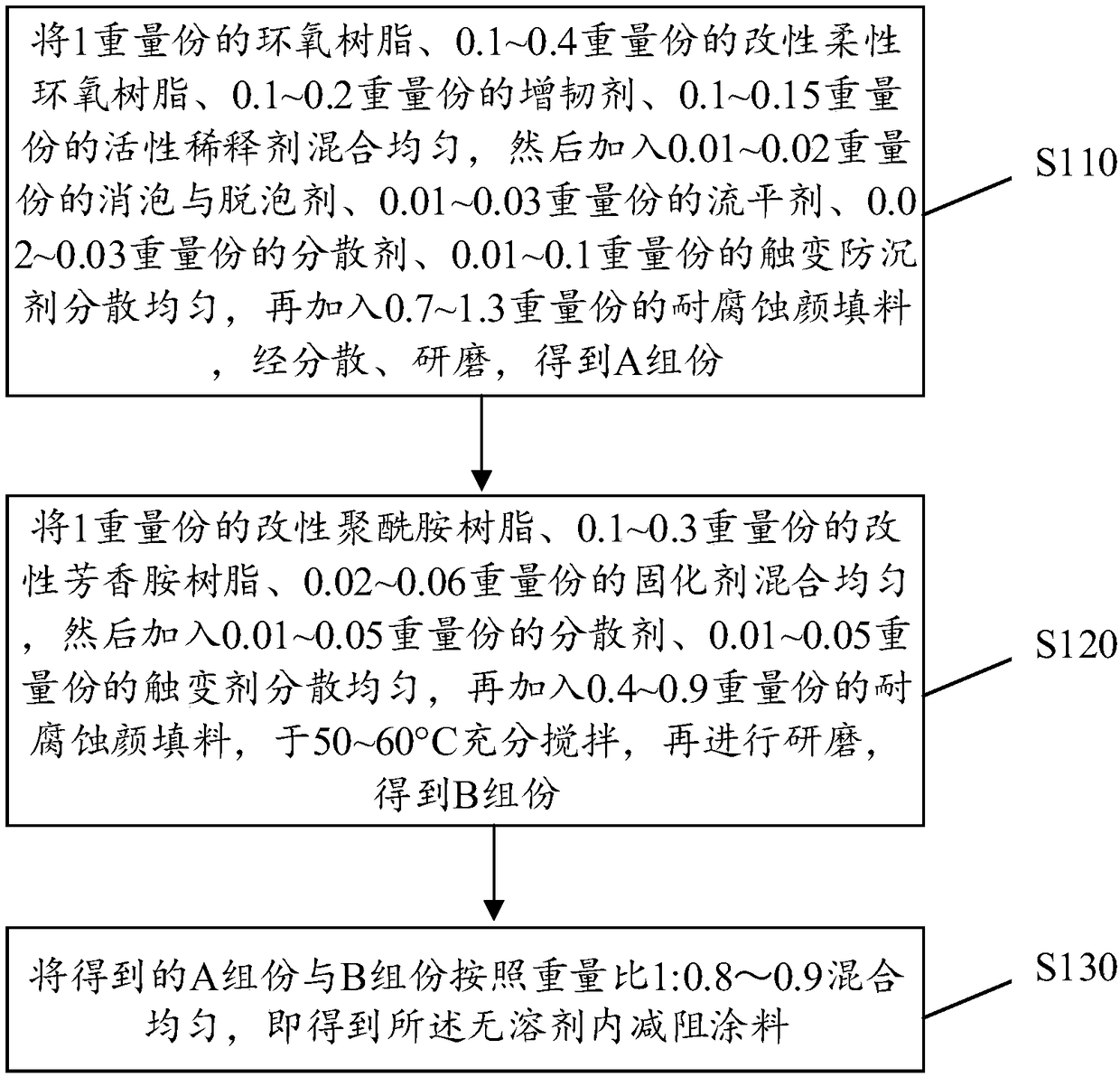

[0050] On the other hand, based on the same inventive concept, the embodiment of the present application provides a method for preparing the above-mentioned solvent-free internal drag-reducing coating, such as figure 1 As shown, it specifically includes the following steps:

[0051] Step S110: Mix 1 part by weight of epoxy resin, 0.1-0.4 parts by weight of modified flexible epoxy resin, 0.1-0.2 parts by weight of toughening agent, and 0.1-0.15 parts by weight of reactive diluent, and then add 0.01 ~0.02 parts by weight of defoaming and defoaming agent, 0.01~0.03 parts by weight of leveling agent, 0.02~0.03 parts by weight of dispersant, 0.01~0.1 parts by weight of thixotropic anti-settling agent, and then add 0.7~1.3 parts by weight Corrosion-resistant pigments and fillers in parts by weight are dispersed and ground to obtain component A;

[0052] Step S120: Mix 1 part by weight of modified polyamide resin, 0.1-0.3 parts by weight of modified aromatic amine resin, and 0.02-0....

Embodiment 1

[0060] 1 weight part of low viscosity epoxy resin E54, 0.3 weight part of modified flexible epoxy resin (EPIKOTE 874L-X-90), 0.10 weight part of phthaloyl polyether ketone, 0.1 weight part Parts of isomerized monocarboxylic acid glycidyl ester (CARDURA E-10P) was dispersed and dissolved, and then 0.01 parts by weight of defoaming and defoaming agent (BYK-A530), 0.02 parts by weight of fluorocarbon modified polyacrylic acid leveling agent were added (AFCONA-3777), 0.02 parts by weight of low molecular weight unsaturated carboxylic acid polymer high-efficiency dispersant (BYK-P104S) high-speed dispersion, while stirring, add 0.01 parts by weight of modified fumed silica (Degussa fumed silica Silicon R972), 0.2 parts by weight of 800 mesh quartz powder, 0.3 parts by weight of 800 mesh wollastonite powder, 0.3 parts by weight of talc powder of 800 mesh and 0.3 parts by weight of iron oxide red, stirred at high speed for 0.5h, and ground for 0.5h with a sand mill. Filtrate the mate...

Embodiment 2

[0062] 1 weight part of low-viscosity epoxy resin E54, 0.2 weight part of modified flexible epoxy resin (EPIKOTE 874L-X-90), 0.10 weight part of phthaloyl polyether ketone, 0.1 weight part Parts of isomeric monocarboxylic acid glycidyl ester (CARDURA E-10P) were dispersed and dissolved, and then 0.02 parts by weight of defoaming and defoaming agent (BYK-A530), 0.02 parts by weight of fluorocarbon modified polyacrylic acid leveling agent ( AFCONA-3777), 0.03 parts by weight of low molecular weight unsaturated carboxylic acid polymer high-efficiency dispersant (BYK-P104S) high-speed dispersion, while stirring, add 0.03 parts by weight of modified fumed silica (Degussa fumed silica R972 ), 0.2 parts by weight of 800 mesh quartz powder, 0.3 parts by weight of 800 mesh wollastonite powder, 0.3 parts by weight of 800 mesh talcum powder and 0.3 parts by weight of iron oxide red, after stirring at high speed for 0.5h, grind 1h with a sand mill, and filter the material Prepare a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com