Thin-coating type solvent-free coating for mechanical engineering equipment and preparation method of thin-coating type solvent-free coating

A solvent-free coating and mechanical engineering technology, applied in the field of coatings, can solve the problems of thick film formation, inability to realize promotion and application, and inability to achieve thin coating properties, and achieve excellent wear resistance, excellent weather resistance, anti-corrosion and waterproof performance , Excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

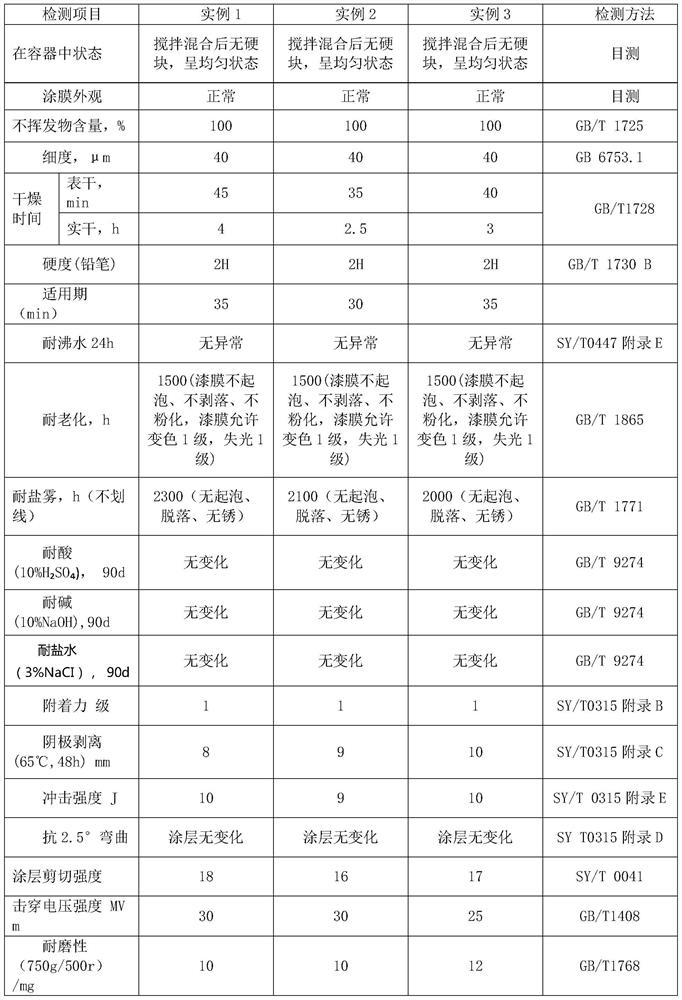

[0024] A thin coating type solvent-free coating component A raw material weight composition for mechanical engineering equipment is shown in the following table:

[0025]

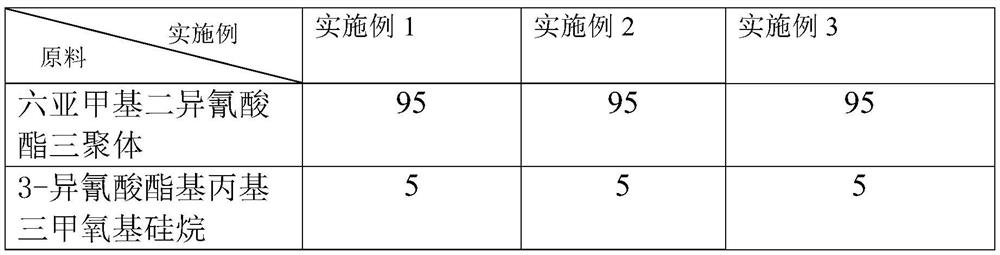

[0026] A kind of thin coating type solvent-free coating component B raw material weight composition for mechanical engineering equipment is shown in the following table:

[0027]

[0028] The wetting and dispersing agent is BYK-108. The polyether polyols are PPG600 and PPG1000. The mass ratio of PPG600 and PPG1000 is 6:10. The hydrophobic agent is polyether modified silicone oil. The mass ratio of component A to component B is 4:1.

[0029] A kind of thin coating type solvent-free coating for mechanical engineering equipment of embodiment 1-3 is prepared by the following method:

[0030] According to the raw material formula, polyaspartic acid ester resin, wetting and dispersing agent, pigment, precipitated barium sulfate, silicon micropowder, anti-dust additive, defoamer, leveling agent, polyethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com