Highly-flame-retardant transparent PET material and preparation method thereof

A high flame retardant and transparent technology, applied in the field of polymer materials, can solve the problems of low practicability, PET material melt strength, dimensional stability, barrier property, heat resistance, etc., and achieve high practicability and surface transparency Glossy, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

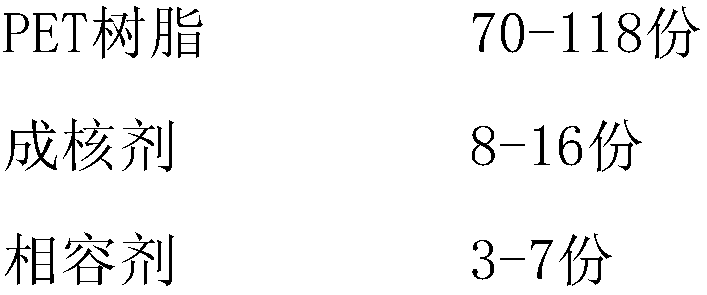

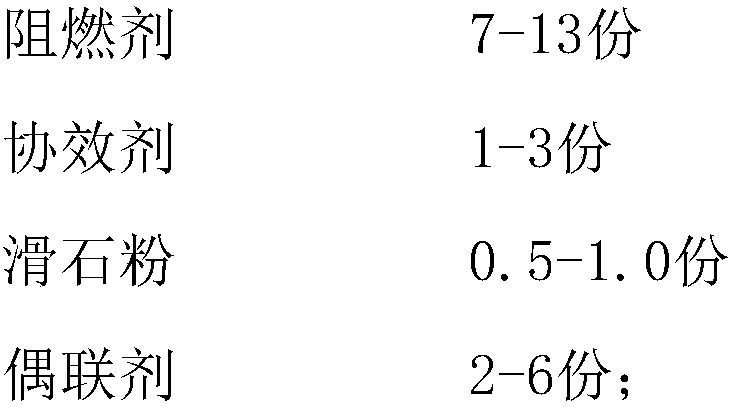

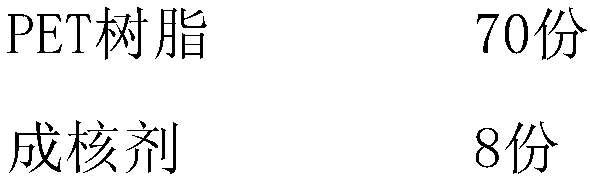

[0033] A highly flame-retardant transparent PET material, the transparent PET material includes the following raw materials by weight:

[0034]

[0035]

[0036] The nucleating agent is composed of 2,2'-methylene bis(4,6-tert-butylphenol)phosphine aluminum salt, dibenzylidene sorbitol and two (p-chloro-substituted benzylidene) sorbitol in a weight ratio of 2.5 :1.2:0.8 mixture.

[0037] The compatibilizer is chlorinated polyethylene.

[0038] The flame retardant is tris(2,3-dibromopropyl) isocyanurate.

[0039] The synergist is antimony trioxide.

[0040] The coupling agent is vinyltriethoxysilane.

[0041] The transparent PET material also includes 1 part of heat-resistant agent, which is magnesium silicide.

[0042] The transparent PET material also includes 0.5 part of lubricant, and the lubricant is glycerol trihydroxystearate.

[0043] The transparent PET material also includes 2.4 parts of antioxidant, and the antioxidant is 1,3,5-tris(3,5 tert-butyl-4-hydroxy...

Embodiment 2

[0048] A highly flame-retardant transparent PET material, the transparent PET material includes the following raw materials by weight:

[0049]

[0050]

[0051] The nucleating agent is composed of 2,2'-methylene bis(4,6-tert-butylphenol)phosphine aluminum salt, dibenzylidene sorbitol and two (p-chloro-substituted benzylidene) sorbitol in a weight ratio of 2.8 :1.3:0.9 mixture.

[0052] The compatibilizer is methacrylate-acrylate copolymer.

[0053] The flame retardant is tribromophenol and / or aluminum tripolyphosphate.

[0054] The synergist is zinc stannate and / or zinc molybdate.

[0055] The coupling agent is anilinomethyltriethoxysilane.

[0056] The transparent PET material also includes 2 parts of heat-resistant agent, and the heat-resistant agent is ceramic fiber.

[0057] The transparent PET material also includes 1 part of lubricant, which is n-butyl stearate.

[0058] The transparent PET material also includes 2.6 parts of antioxidant, and the antioxidant ...

Embodiment 3

[0063] A highly flame-retardant transparent PET material, the transparent PET material includes the following raw materials by weight:

[0064]

[0065] The nucleating agent is composed of 2,2'-methylene bis(4,6-tert-butylphenol)phosphine aluminum salt, dibenzylidene sorbitol and two (p-chloro-substituted benzylidene) sorbitol in a weight ratio of 3 :1.5:1.0 mixture.

[0066] The compatibilizer is natural rubber grafted polymethyl methacrylate and / or styrene grafted maleic anhydride.

[0067] The flame retardant is tetrabromophthalic anhydride and / or octabromoether.

[0068] The synergist is magnesium silicate and / or zinc borate.

[0069] The coupling agent is γ-methacryloxypropyltrimethoxysilane and / or vinyltris(β-methoxyethoxy)silane.

[0070] The transparent PET material also includes 3 parts of heat-resistant agent, and the heat-resistant agent is lignocellulose.

[0071] The transparent PET material also includes 1.5 parts of lubricant, and the lubricant is N,N,-et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com