Sublimation purification device for ultra-high purity metallocene source and ultra-high purity metallocene source extraction method thereof

A metallocene, ultra-high technology, applied in the precursor of high-purity metallocene chemical vapor deposition and atomic layer deposition thin film technology, sublimation purification equipment for ultra-high-purity metallocene sources, sublimation purification of high-purity metallocene sources, can solve ultra-high The purity of metal-organic sources relies on imports, cannot meet high-purity requirements, and metallocene sources have high melting and boiling points, so as to achieve the effects of accelerating uniform heat transfer, easy replacement, and accelerated sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

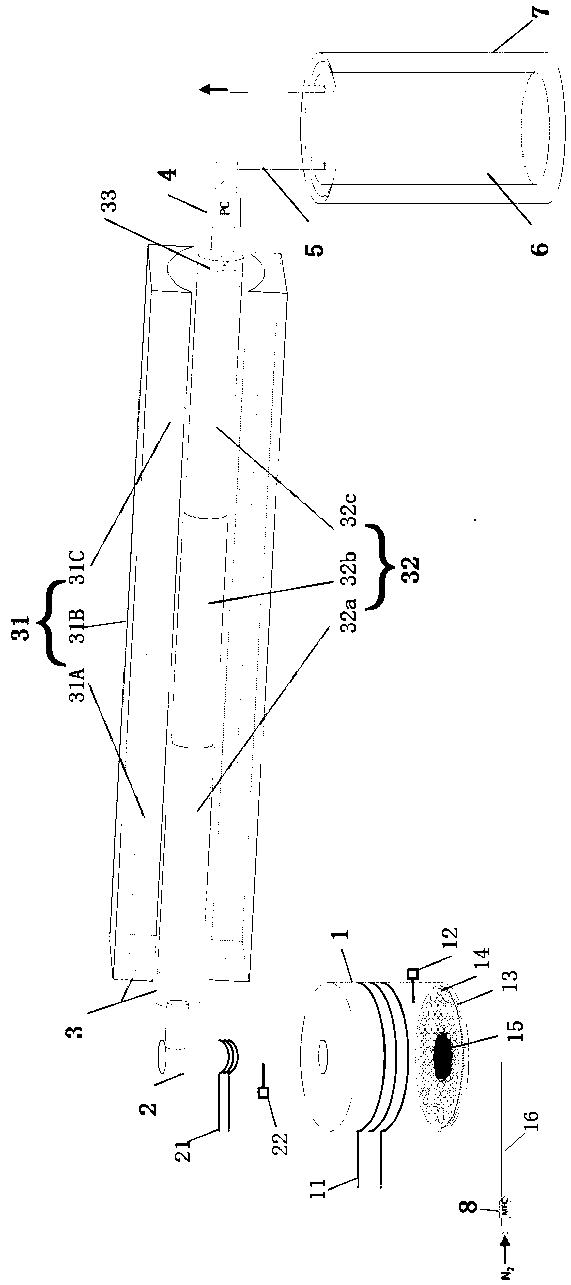

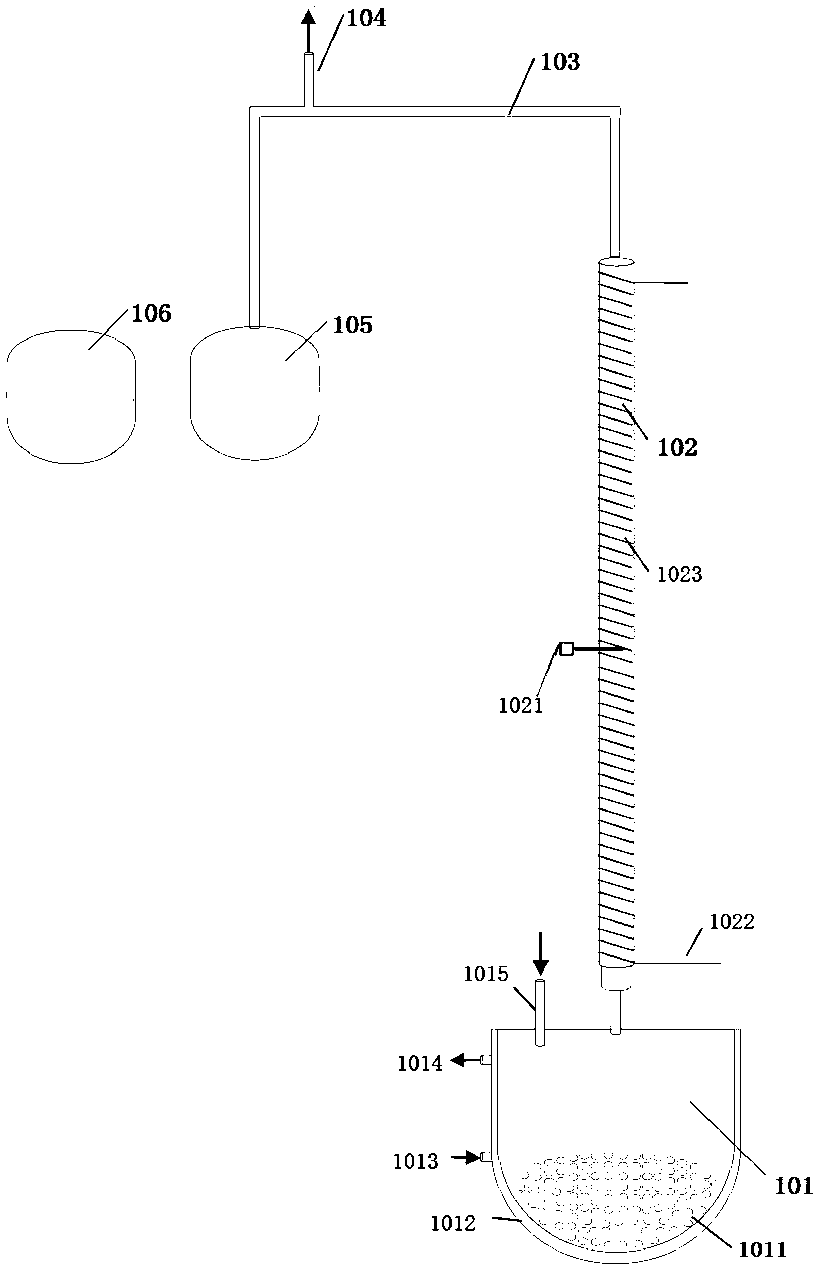

[0038] Such as figure 1 As shown, the sublimation purification device of the ultra-high-purity metallocene source includes a reactor 1, a buffer tube 2, a gradient sublimation tube 3, and a front fraction collection tank 6,

[0039] The reactor 1 is a reaction place, its interior is hollow, the bottom is provided with an inert gas inlet pipe 1616, the interior is provided with a gas dispersion plate 13, the exterior is provided with a first heating belt 11 and a first thermal resistance 12, and the inert gas enters The air pipe 16 is provided with a flow controller 8; the first thermal resistor 12 controls the temperature of the first heating belt 11;

[0040] Inert particles 14 are distributed on the gas dispersion plate 13. The reactor 1 has a magnetic stirring function and a built-in magnetic stirrer 15. The inert particles 14 are stirring balls made of polytetrafluoroethylene-wrapped magnetic steel. The diameter ranges from In 5-20mm, at least one diameter specification; ...

Embodiment 2

[0050] In this embodiment, the outer diameter of the quartz tube 32 is 220 mm, and the length of the tube is 1540 mm. Others are the same as in Embodiment 1.

Embodiment 3

[0052] A method for purifying an ultra-high-purity metallocene source using the device described in Example 1, the steps are:

[0053] (1) Place the sublimation purification device of the ultra-high-purity metallocene source described in Example 1 in a glove box protected by an inert atmosphere;

[0054] (2) The inert gas is filled into the sublimation purification device of the ultra-high-purity metallocene source described in Example 1, the inert atmosphere in step (1) and the inert gas in step (2) are high-purity nitrogen, and the mass fraction is not less than 7N; the mass fraction Not less than 7N means the gas purity is not less than 99.99999%;

[0055] (3) Mix 2.5 kg of metallocene source crude product with 2 kg of inert particles 14 and add them into the reactor 1 through the raw material feeding port, and then connect the raw material feeding port and the opening of the head end of the buffer tube 2 through the first clamp; The inert particle 14 is a stirring ball ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com