Method for preparing phthalic acid from m-xylene and p-xylene through mixing and oxidation

A technology of p-xylene and m-xylene, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve problems that do not involve mixed xylene catalyst system and oxidation reaction process, and achieve simplified raw materials Separation process, reduced equipment corrosion, high yield effect

Inactive Publication Date: 2018-07-20

CHINA PETROLEUM & CHEM CORP

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] CN1314878A proposes a method for separating pure terephthalic acid and isophthalic acid from mixed xylene co-oxidation product slurry, but does not involve the catalyst system and oxidation reaction process used for mixed xylene oxidation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-8

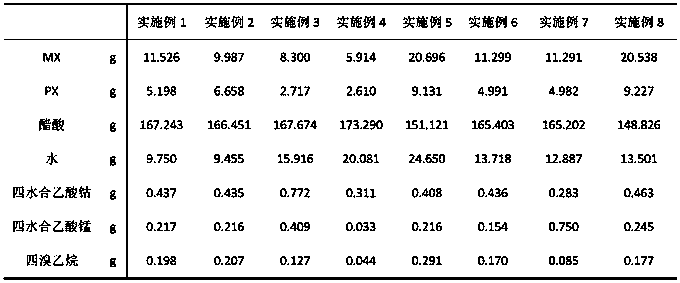

[0027] Using the above reaction process, the PX and MX mixed oxidation reactions were carried out under different conditions. The addition amount of each reactant is listed in Table 1.

[0028] Table 1. The reactant add-on of embodiment 1~8

[0029]

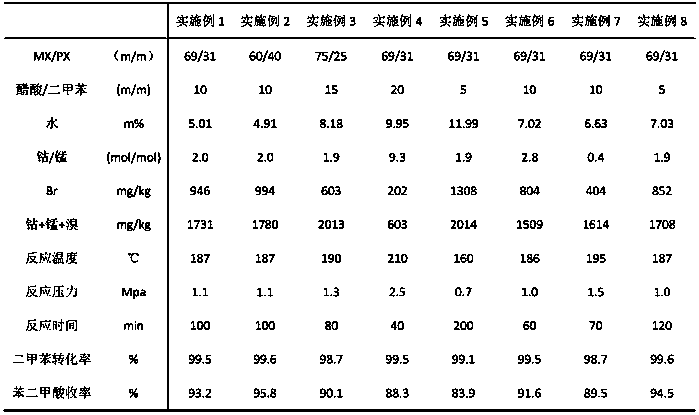

[0030] Table 2. The reaction condition and reaction result of embodiment 1~8

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for preparing phthalic acid from m-xylene and p-xylene through mixing and oxidation. The method comprises the following steps: putting a mixed xylene raw material ofMX / PX (M-Xylene / P-Xylene) in a ratio of 60-40 to 75-25, an acetic acid solvent in a mass ratio of 5-1 to 20-1 to the mixed xylene, and a Co-Mn-Br three-way catalyst into an oxidation reactor, introducing air, enabling the components to react for 40-200 minutes under conditions that the air speed is 2000-3000mL / minute, the temperature is 160-210 DEG C and the pressure is 0.5-2.5MPa so as to obtainslurry with mixed benzol dioctyl phthalate, and performing separation and refining. Due to mixing and oxidation of MX and PX, the separation cost of MX and PX can be reduced; a small amount of the catalyst is used, a small amount of tetrabromoethane is used as a bromide, and equipment corrosion can be alleviated; the obtained mixed oxide is relatively high in yield; the market competitiveness of the product can be improved.

Description

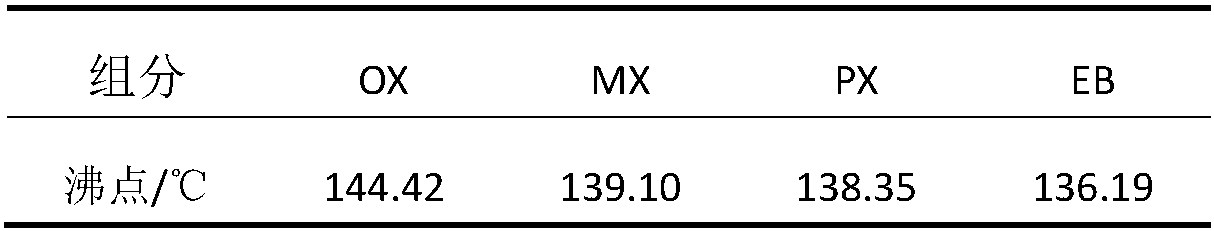

technical field [0001] The invention relates to a method for preparing phthalic acid by mixed oxidation of m-xylene (MX) and p-xylene (PX), belonging to the technical field of organic chemical industry. Background technique [0002] Phthalic acid is an important organic compound and a raw material for the production of various chemical products. Among them, purified terephthalic acid (PTA) is mainly used to produce polyethylene terephthalate (PET), which is further used to produce polyester fibers and films. Purified isophthalic acid (PIA) can be used to produce unsaturated polyester resin and alkyd resin, and one of its main uses is to copolymerize with PTA to produce copolyester. These two phthalic acids are currently produced by liquid-phase air oxidation using the corresponding xylene isomers, respectively. The oxidation process of the two kinds of phthalic acid is relatively similar, both use high-purity monomer as raw material, acetic acid as solvent, Co-Mn-Br three-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C51/265C07C63/24C07C63/26B01J27/128

CPCB01J27/128C07C51/265C07C63/24C07C63/26

Inventor 崔凤霞李军段大勇魏文静张立东崔晓雪

Owner CHINA PETROLEUM & CHEM CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com