Process for preparing and extracting L-glutamine

A glutamine and process technology, applied in the field of preparation and extraction of L-glutamine, can solve the problems of high consumption of acid and alkali for elution and regeneration, large amount of exchange resin, and high product cost, and achieves the promotion of utilization and transport, and reduction of bacteria. The content of body and impurities, the effect of improving the efficiency of acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A process for preparing and extracting L-glutamine, comprising the steps of:

[0040] 1) Fermentation: Brevibacterium flavum ATCC14067 seed solution (1×10 8 cfu / ml) was inserted into the fermentation medium according to the inoculum size of 5%, and fermented continuously for 50 hours to obtain the L-glutamine fermentation broth; the temperature during the fermentation process was controlled at 30°C, the pH was controlled at 6.8, and the pH was controlled at 6.8 during the fermentation process. The glucose concentration is not lower than 15g / L;

[0041] Wherein the fermentation medium is (mass percentage): glucose 15%, corn steep liquor 2%, ammonium sulfate 1%, magnesium sulfate 0.3%, dipotassium hydrogen phosphate 0.2%, potassium dihydrogen phosphate 0.2%, sodium chloride 0.1%, sulfuric acid Manganese 0.001%, ferrous sulfate 0.001%, V B1 0.0001%, pH 6.8;

[0042]Utilize the inorganic ceramic membrane to filter the fermented liquid to obtain the filtrate A (the L-glu...

Embodiment 2

[0053] A process for preparing and extracting L-glutamine, comprising the steps of:

[0054] 1) Fermentation: Brevibacterium flavum ATCC14067 seed solution (1×10 8 cfu / ml) was inserted into the fermentation medium according to the inoculum size of 5-7%, and fermented continuously for 45 hours to obtain the L-glutamine fermentation liquid; the temperature during the fermentation process was controlled at 30°C, and the pH was controlled at 6.8. Control the glucose concentration in the medium to not less than 15g / L;

[0055] Wherein the fermentation medium is (mass percentage): glucose 15%, corn steep liquor 2%, ammonium sulfate 1%, magnesium sulfate 0.3%, dipotassium hydrogen phosphate 0.2%, potassium dihydrogen phosphate 0.2%, sodium chloride 0.1%, sulfuric acid Manganese 0.001%, ferrous sulfate 0.001%, V B1 0.0001%, pH 6.8;

[0056] Utilize the inorganic ceramic membrane to filter the fermented liquid to obtain the filtrate A (the L-glutamine content is 2.83%) and separate...

Embodiment 3

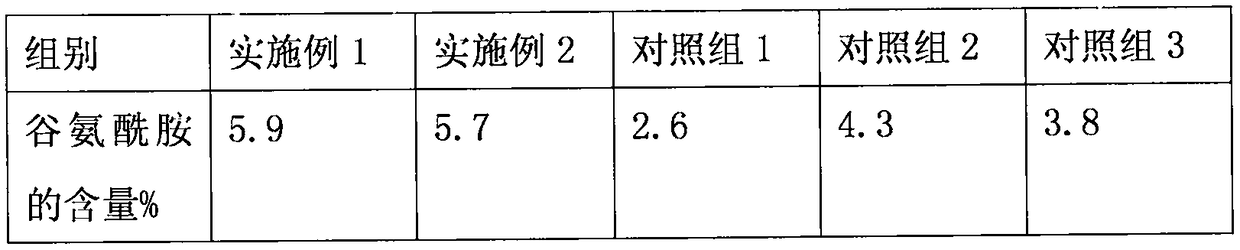

[0067] Taking Example 1-2 as an example, the content of glutamine in the filtrate B was detected respectively; at the same time, a control group was also set up, wherein, the control group 1 was: only dialysis culture treatment was carried out, tourmaline powder and heat treatment were not used, and the rest were the same as in the embodiment 1; Control group 2: After the fermentation is completed, carry out tourmaline powder and dialysis culture treatment, do not use heat treatment, the rest are the same as in Example 1; Control group 3: After the fermentation is completed, carry out heat treatment and dialysis culture treatment, do not use tourmaline powder treatment, the rest With embodiment 1; Detect the content of glutamine in each group filtrate B, concrete results are shown in Table 1:

[0068] Table 1

[0069]

[0070] Conclusion: As shown in Table 1, the dialysis culture treatment of the fermentation waste cells can still produce a relatively high concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com