High capacitance density capacitor comprising series structure dielectric and preparation method thereof

A capacitance density and capacitor technology, applied in the field of capacitors, can solve the problems of high thickness preparation process, high production cost, and low yield rate, and achieve the effects of reducing production process requirements, improving yield rate, and high capacitance density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

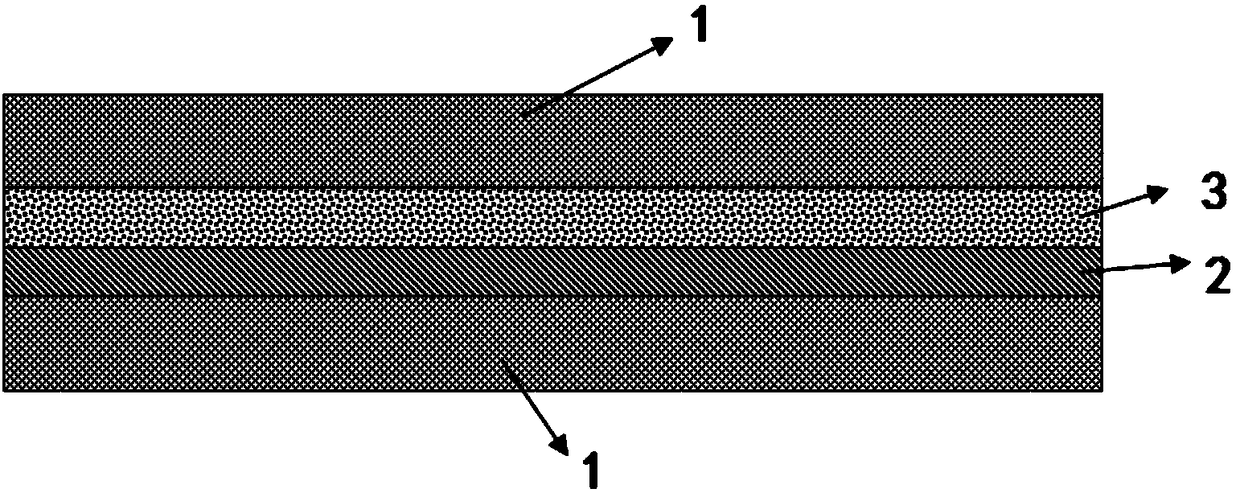

[0090] This embodiment provides a capacitor, and the capacitor includes a dielectric composed of a positive dielectric material and a negative dielectric material connected in series.

[0091] The dielectric constant of the positive dielectric material is a positive value, which is a polymer-based composite material comprising 4.5wt% carbon nanotubes and 95.5wt% epoxy resin;

[0092] The dielectric constant of the negative dielectric material is a negative value, which is a polymer-based composite material comprising 16wt% carbon nanotubes and 84wt% epoxy resin;

[0093] Both electrodes of the capacitor are copper foils.

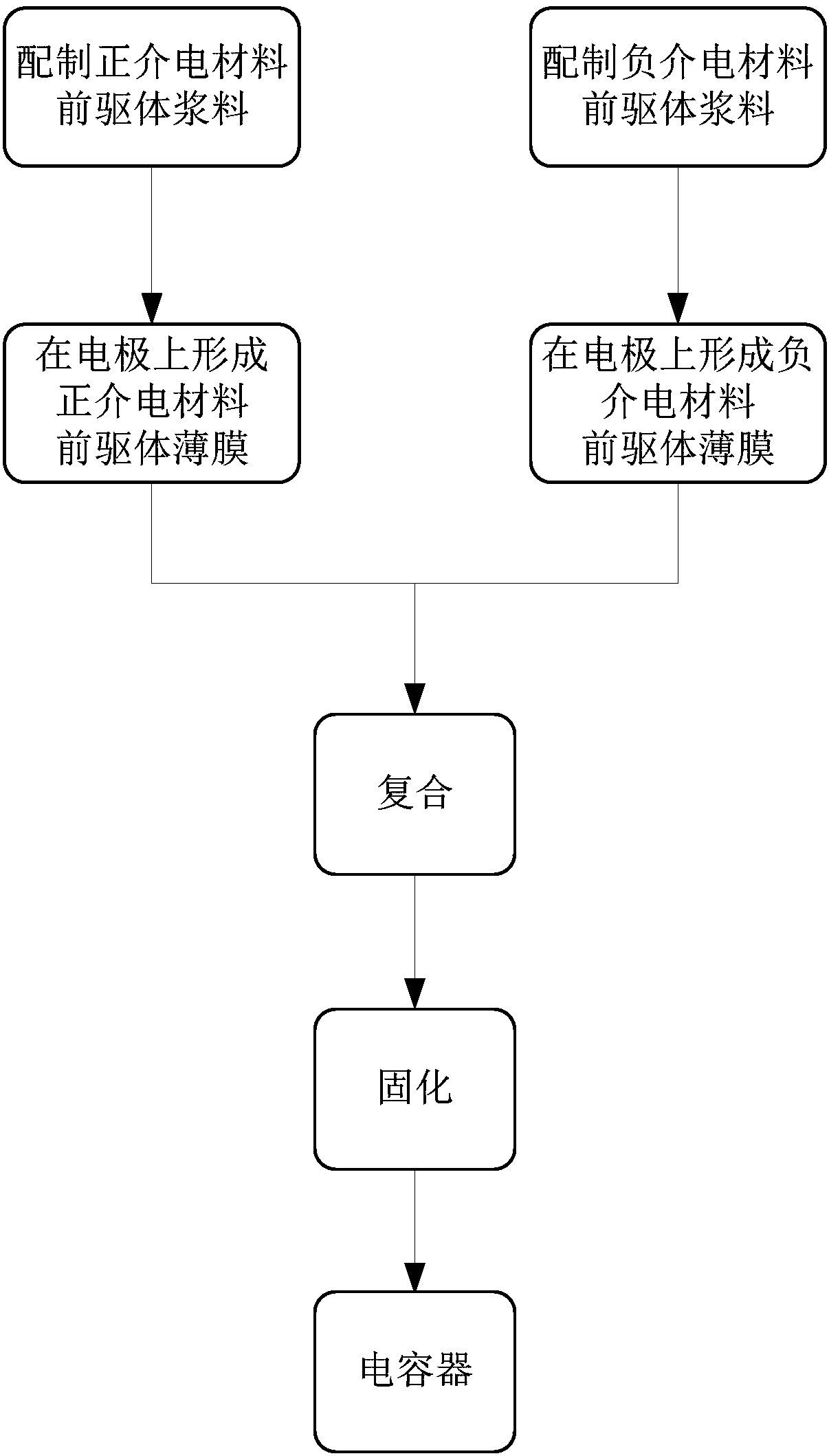

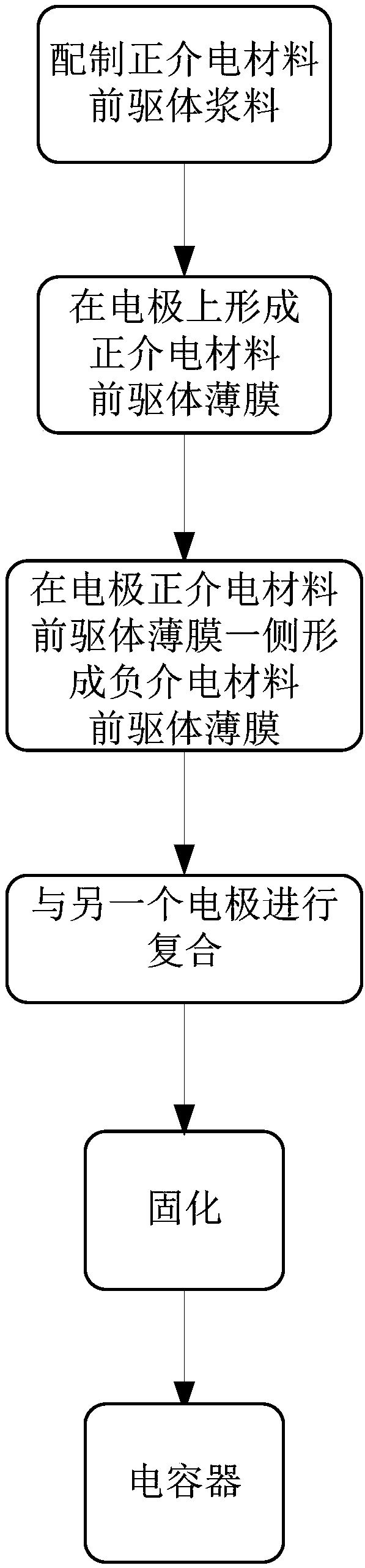

[0094] Preparation:

[0095] (1) Weigh 0.5g of carbon nanotubes, 10g of epoxy resin Epon828, 0.5g of dicyandiamide, 5g of N,N-dimethylformamide, 0.1g of 2-methylimidazole, and 10g of butanone at a speed of 1000rpm Ball milled for 12 hours to obtain a positive dielectric material precursor slurry, and then use a coater to coat the slurry on a copper foil wi...

Embodiment 3

[0101] This embodiment provides a capacitor, and the capacitor includes a dielectric composed of a positive dielectric material and a negative dielectric material connected in series.

[0102] The dielectric constant of the positive dielectric material is a positive value, which is a polymer matrix composite material comprising 65wt% barium titanate ceramic particles and 35wt% epoxy resin;

[0103]The dielectric constant of the negative dielectric material is a negative value, and it is a polymer matrix composite material comprising 59wt% silver particles and 41wt% epoxy resin;

[0104] Both electrodes of the capacitor are copper foils.

[0105] Preparation:

[0106] (1) Weigh 20g of barium titanate, 10g of epoxy resin Epon828, 0.5g of dicyandiamide, 5g of N,N-dimethylformamide, 0.1g of 2-methylimidazole, 10g of butanone, and ball mill at a speed of 1000rpm 12h, obtain the positive dielectric material precursor slurry, and then use a coating machine to coat the slurry on a c...

Embodiment 4

[0112] This embodiment provides a capacitor, and the capacitor includes a dielectric composed of a positive dielectric material and a negative dielectric material connected in series.

[0113] The dielectric constant of the positive dielectric material is a positive value, which is a polymer matrix composite material of 32wt% silver particles and 68wt% epoxy resin;

[0114] The dielectric constant of the negative dielectric material is a negative value, which is a polymer-based composite material comprising 4.5wt% graphene and 95.5wt% epoxy resin;

[0115] Both electrodes of the capacitor are copper foils.

[0116] Preparation:

[0117] (1) Weigh 5g of silver particles, 10g of epoxy resin Epon828, 0.5g of dicyandiamide, 5g of N,N-dimethylformamide, 0.1g of 2-methylimidazole, 10g of methyl ethyl ketone, and ball mill at 1000rpm for 12h , to obtain a positive dielectric material precursor slurry, and then use a coater to coat the slurry on a copper foil with a thickness of 35 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com