Functional gradient layer knitted fabric and preparation method thereof

A functional gradient and knitted fabric technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of fabric smoothness, softness, poor drapability, inability to weave high-count yarns, and unsuitable sheathing, etc., to ensure natural Antibacterial, mildew and deodorant, reducing the use of chemical finishing agents, improving the effect of anti-pilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

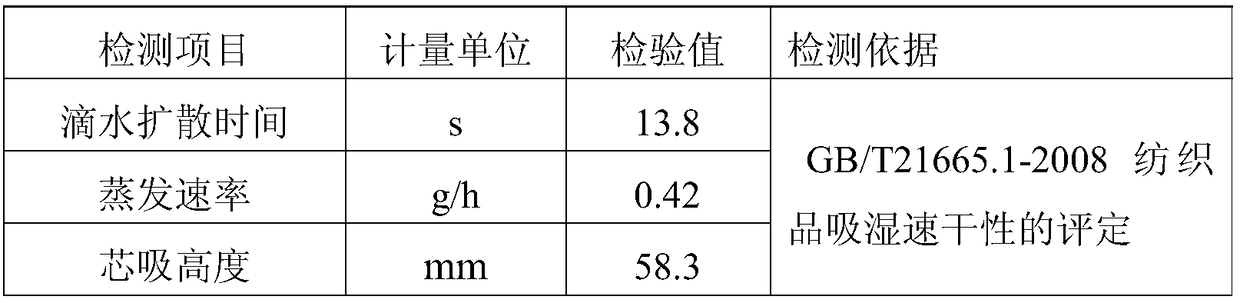

[0038] Embodiment 1, functionally gradient knitted fabric and performance test thereof

[0039] 1. Preparation of knitted fabric

[0040] For inner and middle layers:

[0041] The ratio of hemp / cotton / polyester blended yarn is: 35% hemp, 40% cotton, 25% polyester; the linear density of the yarn is 29Tex.

[0042] For the outer layer:

[0043] 100% hygroscopic and quick-drying polyester filament, fineness: 150D.

[0044] 2. Pre-treatment and post-finishing of knitted fabric

[0045] The pretreatment includes the following steps of enzyme soaking, scouring and bleaching in sequence.

[0046] The enzyme soaking process is:

[0047] a. The formula of bottom bleaching solution: scouring enzyme GJB: water = 1:100 (mass ratio).

[0048] b. Enzyme soaking process: the bleaching solution is raised to 98°C at a rate of 2°C / min, and the temperature of the bleaching solution is maintained for 40 minutes, and then the bleaching solution is lowered to 20°C at a rate of 2°C / min. Keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com