A kind of GM graft modified polyvinyl acetate-based reverse core-shell emulsion and preparation method thereof

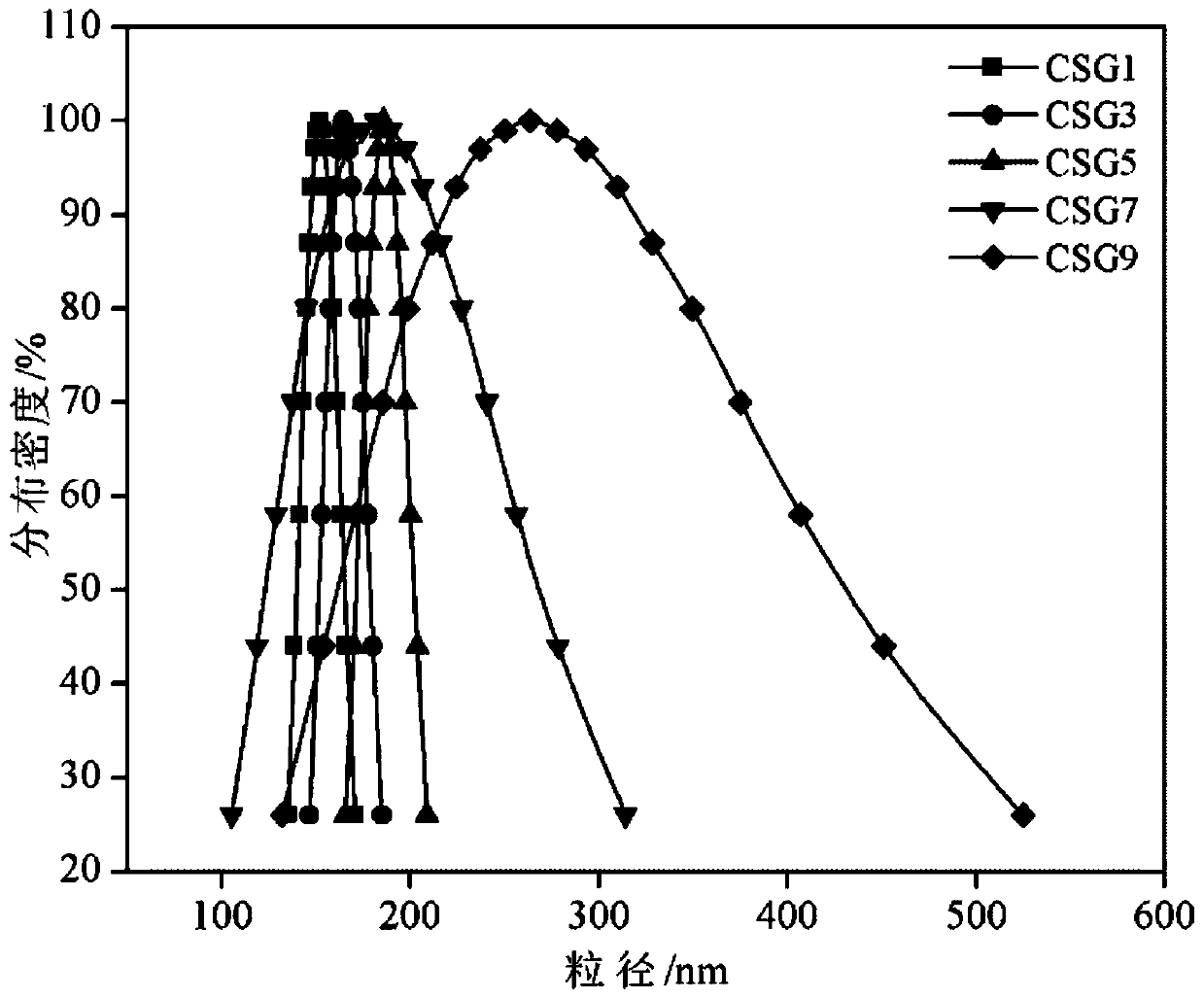

A polyvinyl acetate-based, graft-modified technology, applied in the direction of graft polymer adhesives, adhesive types, adhesives, etc., can solve the problem of limiting the practical application of emulsion adhesives and affecting the uniformity and stability of emulsions , uneven particle size of latex particles, etc., to achieve the effect of improving the adhesive compressive shear wet strength, regular shape without adhesion, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] A GMA graft-modified polyvinyl acetate-based reverse core-shell emulsion, said a GMA graft-modified polyvinyl acetate-based reverse core-shell emulsion is mainly composed of a first core layer monomer, a second core Layer monomers, shell monomers, graft monomers, composite emulsifiers, initiators, pH buffers, deionized water, and functional monomers, the parts by weight are respectively 60 to 70 parts by weight of the first core layer Monomer, 10-20 parts of second core layer monomer, 30-40 parts of shell layer monomer, 1-1.2 parts of graft monomer, 5-6 parts of composite emulsifier, 0.4-0.5 parts of initiator Agent, 0.3-0.5 parts of pH buffering agent, 100-125 parts of deionized water, 0.5-10 parts of functional monomer, the first core layer monomer is vinyl acetate, and the second core layer The monomer is butyl acrylate, the shell monomer is styrene, the graft monomer is maleic anhydride, the composite emulsifier is a mixture of PCA507 and PCA078, and the initiator i...

specific Embodiment approach 2

[0054] According to the preparation method of a kind of GMA graft modified polyvinyl acetate base reverse core-shell emulsion described in specific embodiment one, comprises the following steps:

[0055] Step 1. Take a certain mass of the first core monomer, the second core monomer, the shell monomer, the graft monomer, the composite emulsifier, the initiator, the pH buffer, the deionized water , functional monomer, to be used;

[0056] Step 2, after dissolving the weighed initiator and graft monomer respectively in 10-15% of the total mass of deionized water, stand-by;

[0057] Step 3. Add 70-80% of the total mass of deionized water into the reactor, and add the pH buffer and compound emulsifier into the reactor, raise the temperature to 60°C, stir for 30 minutes, and then add the first nuclear layer monomer total 10-20% of the mass, continue to stir and emulsify for 30 minutes, add 30-50% of the total amount of the initiator aqueous solution prepared in step 2, raise the te...

specific Embodiment approach 3

[0065] A GMA graft-modified polyvinyl acetate-based reverse core-shell emulsion, said a GMA graft-modified polyvinyl acetate-based reverse core-shell emulsion is mainly composed of a first core layer monomer, a second core layer monomer, shell monomer, graft monomer, composite emulsifier, initiator, pH buffer, deionized water, and functional monomer. The first core layer monomer is vinyl acetate. The second core monomer is butyl acrylate, the shell monomer is styrene, the graft monomer is maleic anhydride, and the composite emulsifier is a mixture of PCA507 and PCA078. The initiator is ammonium persulfate, and the pH buffer is NaHCO 3 , the functional monomer is glycidyl methacrylate.

[0066] The parts by weight of the first core layer monomer in a kind of GMA graft modified polyvinyl acetate-based reverse core-shell emulsion described in this embodiment is 60 parts by weight, and the parts by weight of the second core layer monomer The number is 10 parts, the parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com