Preparation method of high-frequency wave-transparent sandwich structure composite material 5G antenna housing

A sandwich structure and composite material technology, applied in antennas, antenna parts, chemical instruments and methods, etc., can solve the problems of unfavorable development of high-performance radomes, high production equipment requirements, and high curing temperature, so as to reduce material costs, The effect of reducing post-processing steps, meeting temperature resistance and wave transmittance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

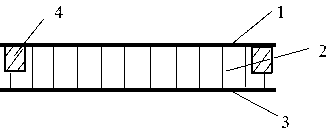

[0027] A method for preparing a high-frequency wave-transparent sandwich structure composite material 5G radome. The radome is a sandwich structure, including an upper skin 1, a lower skin 3, a honeycomb sandwich core material 2 and a bakelite board 4. The preparation method mainly It includes the following steps: first, the modified epoxy resin glue is impregnated with glass fiber to prepare a prepreg, and the glue content of the prepreg is 20%; The layer structure is 90° / 0° / 90°, and the lower skin of the radome is formed after first heating and curing by the autoclave process; the lower skin is covered with honeycomb core material, bakelite board and upper skin in sequence Lay-up of prepreg material, laying adhesive film between the upper and lower skins and the core material, tightly bonded to form a sandwich structure, the second heating and curing to form the radome; the radome panel is painted and processed after machining. The curing process is as follows: the curing te...

Embodiment 2

[0032] A method for preparing a high-frequency wave-transparent sandwich structure composite material 5G radome. The radome is a sandwich structure, including an upper skin 1, a lower skin 3, a honeycomb sandwich core material 2 and a bakelite board 4. The preparation method mainly It includes the following steps: first, the modified epoxy resin glue is impregnated with glass fiber to prepare a prepreg, and the glue content of the prepreg is 40%; The layer structure is +45° / 0° / -45°, and the lower skin of the radome is formed after the first heating and curing by the autoclave process; the honeycomb core material, the bakelite board and the upper skin are sequentially laid on the lower skin Skin prepreg layering, adhesive film between the upper and lower skins and the core material, tightly bonded to form a sandwich structure, the second heating and curing to form the radome; the radome panel is painted and processed after machining. The curing process is as follows: the curing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com