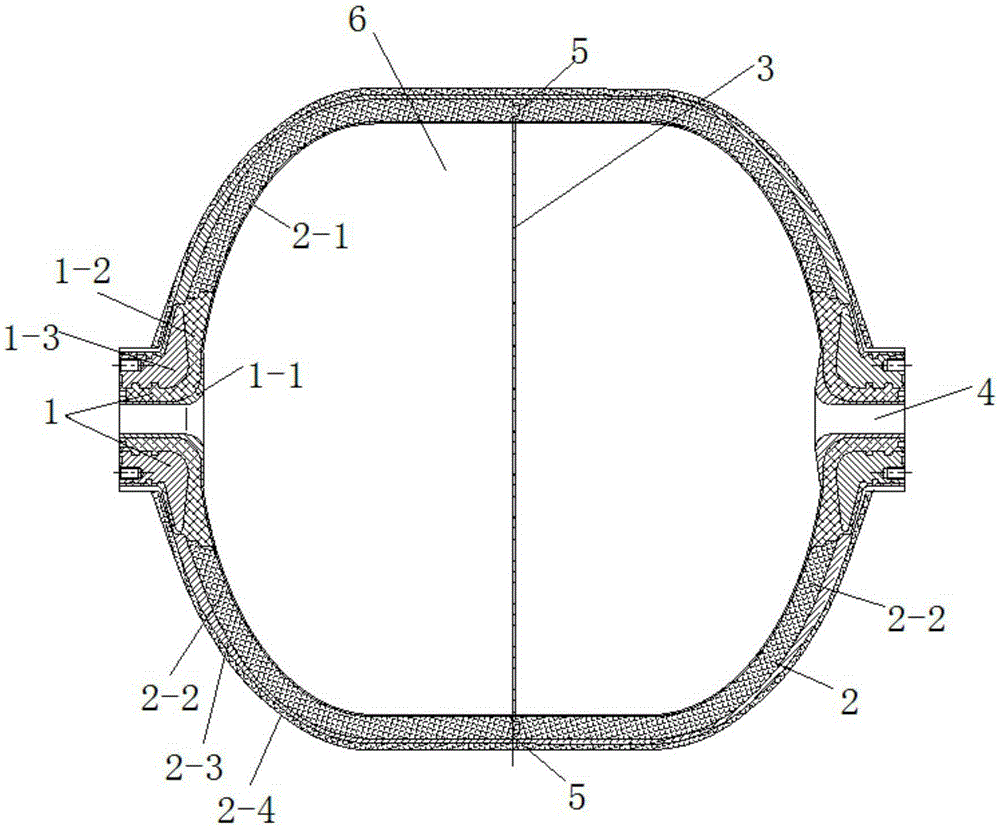

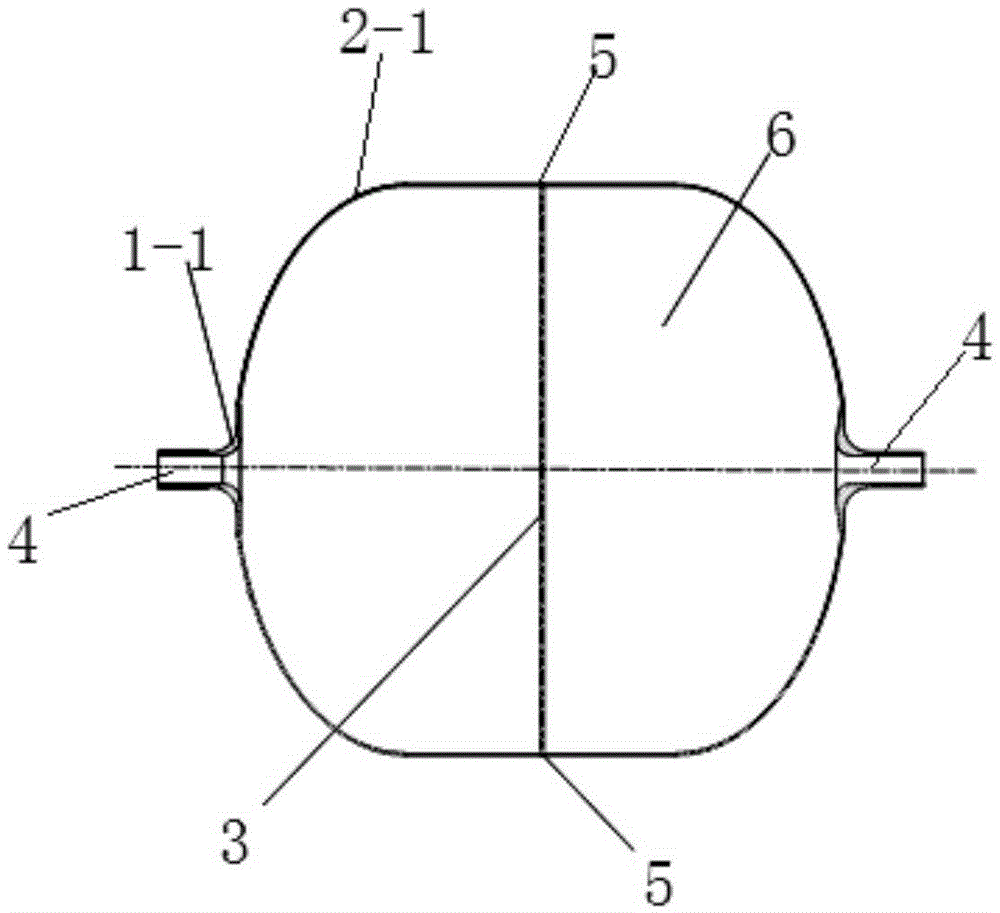

Lightweight high temperature and high pressure composite gas cylinder and manufacturing method thereof

A high temperature and high pressure, manufacturing method technology, applied in the container filling method, the container discharge method, the pressure vessel and other directions, can solve the problems of thick gas cylinder thickness, large negative weight of gas cylinder, etc. The effect of small demoulding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] When the lightweight high-temperature and high-pressure composite gas cylinder is used in a thermal spray attitude control system, the size and performance requirements of the gas cylinder are as follows in Table 1:

[0030] Table 1

[0031]

[0032] The manufacturing method of the lightweight high-temperature and high-pressure composite gas cylinder comprises the following steps:

[0033] 1) Forming of ellipsoidal halves: the stainless steel plate is stretched into two hollow ellipsoidal halves with a thickness of 0.5 mm by stretching method, and the tops of the two ellipsoidal halves are laser-opened and the outer surface is uniformly sand-blown ;

[0034] 2) Sand core molding: Use the two ellipsoid halves formed in step 1) to form sand cores with net dimensions respectively. The specific process of sand core molding is as follows:

[0035] a. Prepare quartz sand adhesive: the components and weight ratio (parts) of quartz sand adhesive are as follows:

[0036] Q...

Embodiment 2

[0047] The product size and performance requirements for using lightweight high-temperature and high-pressure composite gas cylinders in an engineering composite gas cylinder are as follows: Table 3:

[0048] table 3

[0049]

[0050] The manufacturing method of the lightweight high-temperature and high-pressure composite gas cylinder comprises the following steps:

[0051] 1) Ellipsoid forming: the stainless steel plate is stretched into two ellipsoid halves with a thickness of 0.3 mm by stretching method, and the tops of the two ellipsoid halves are laser-opened and the outer surface is evenly sand-blown;

[0052] 2) Sand core molding: Use the two ellipsoid halves formed in step 1) to form sand cores respectively. The specific process of sand core molding is as follows:

[0053] a. Prepare the quartz sand adhesive, the components and weight ratio (parts) of the quartz sand adhesive are as follows:

[0054] Quartz sand: polyvinyl alcohol: starch: water = 380: 10: 0.5: 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com