Epoxy resin conformal coating and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

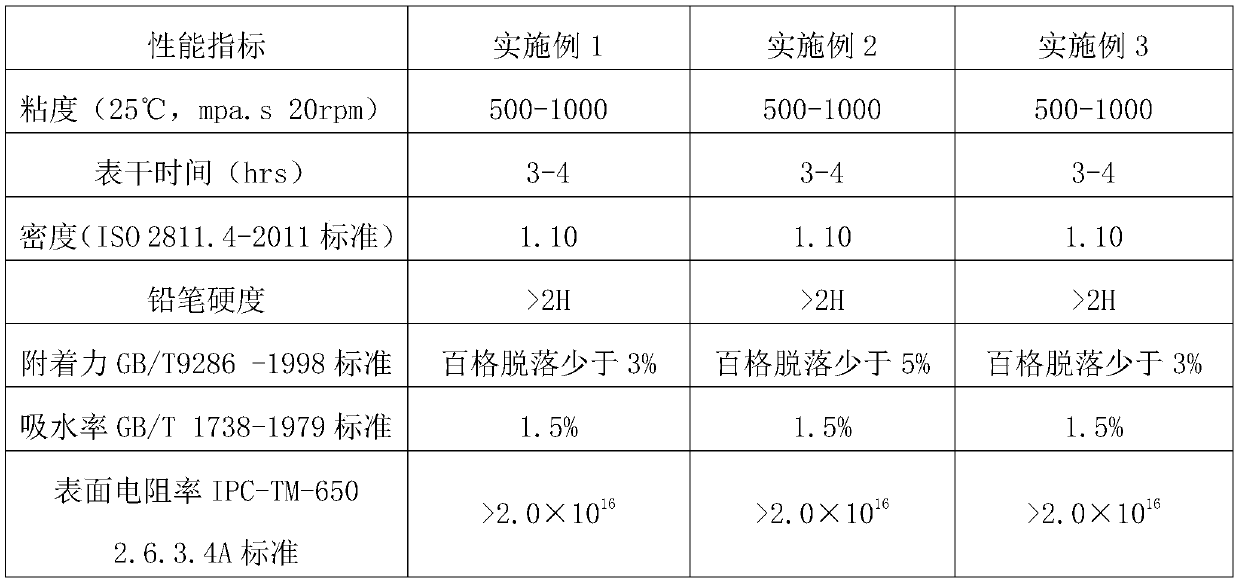

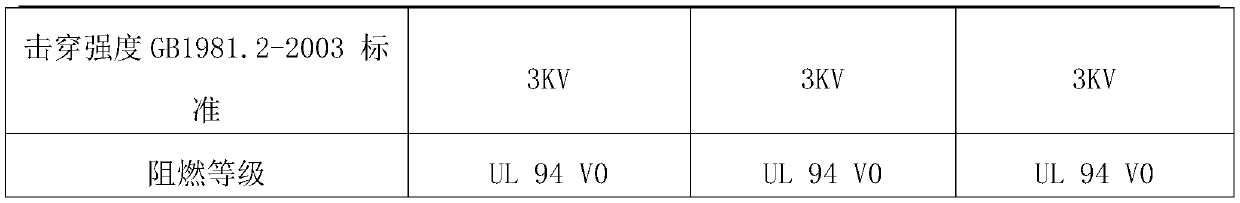

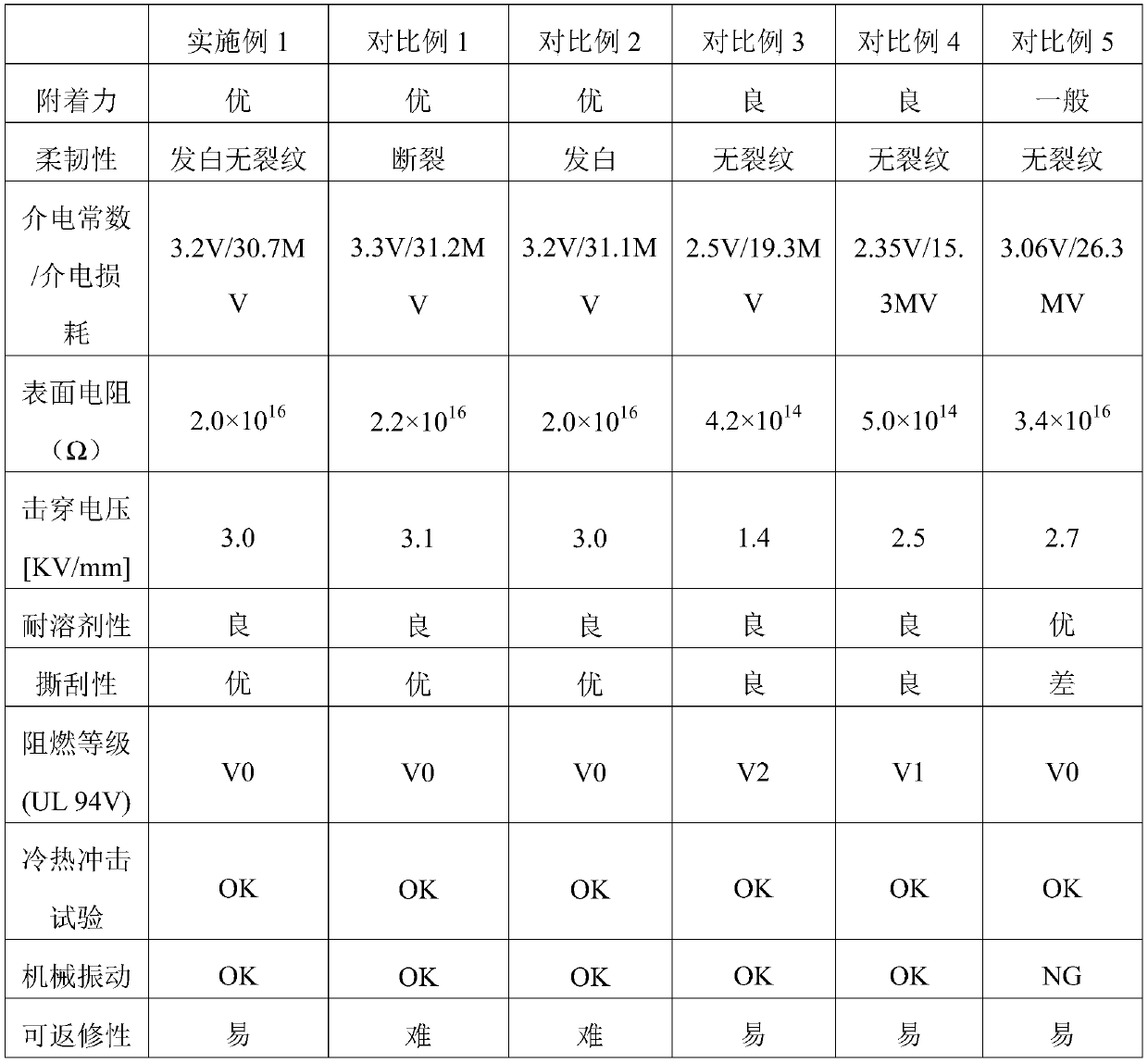

Examples

Embodiment 1

[0037] An epoxy resin conformal paint, consisting of component A and component B at a weight ratio of 2:1, wherein:

[0038] A component is made up of the raw material of following weight part:

[0039] Bisphenol A epoxy resin: Nan Ya NPEF-128 epoxy resin 70 parts;

[0040] Reactive diluent: 15 parts of benzyl glycidyl ether (692 epoxy diluent);

[0041] Core-shell organic filler: 30 parts of high-temperature foaming powder;

[0042] Defoamer: BYK-530 0.3 part;

[0043] Thixotropic agent: 2 parts of fumed silica R202;

[0044] Leveling agent: Dow Corning DC-57 0.5 parts;

[0045] B component is made up of the raw material of following weight part:

[0046] 70 parts of modified cycloaliphatic amines;

[0047] Polyetheramine: D230 30 parts;

[0048] Inactive diluent: 10 parts of benzyl alcohol.

[0049] The preparation method of the epoxy resin conformal coating of the present embodiment comprises the following steps:

[0050] (1) Mix bisphenol A epoxy resin, reactive dil...

Embodiment 2

[0054] An epoxy resin conformal paint, consisting of component A and component B at a weight ratio of 2:1, wherein:

[0055] A component is made up of the raw material of following weight part:

[0056] Bisphenol A epoxy resin: Dow DEER331 epoxy resin 60 parts;

[0057] Reactive diluent: 12 parts of p-tert-butylphenol glycidyl ether;

[0058] Core-shell organic filler: 20 parts of high-temperature foaming powder;

[0059] Defoamer: BYK-055 0.1 part;

[0060] Thixotropic agent: 1 part of fumed silica R202;

[0061] Leveling agent: 0.7 parts of Tego450 from Germany;

[0062] B component is made up of the raw material of following weight part:

[0063] 45 parts of modified cycloaliphatic amines;

[0064] Polyetheramine: 20 parts of D230;

[0065] Inactive diluent: 30 parts of benzyl alcohol.

[0066] The preparation method of the epoxy resin conformal coating of the present embodiment comprises the following steps:

[0067] (1) Mix bisphenol A epoxy resin, reactive dilue...

Embodiment 3

[0071] An epoxy resin conformal paint, consisting of component A and component B at a weight ratio of 2:1, wherein:

[0072] A component is made up of the raw material of following weight part:

[0073] Bisphenol A epoxy resin: Shell EP828 epoxy resin 90 parts;

[0074] Reactive diluent: 20 parts of phenyl glycidyl ether (PGE);

[0075] Core-shell organic filler: 12 parts of high-temperature expansion microspheres;

[0076] Defoamer: Hemings 5300 0.5 part;

[0077] Thixotropic agent: fumed silica R974 3 parts;

[0078] Leveling agent: 1 part of German Tego450;

[0079] B component is made up of the raw material of following weight part:

[0080] 60 parts of modified cycloaliphatic amines;

[0081] Polyetheramine: D230 15 parts;

[0082] Inactive diluent: 20 parts of cardanol oil.

[0083] The preparation method of the epoxy resin conformal coating of the present embodiment comprises the following steps:

[0084] (1) Mix bisphenol A epoxy resin, reactive diluent, core-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com