Micro-fluidic chip system capable of regulating emulsion formation

A microfluidic chip and adjustable technology, which can be applied in the direction of liquid separation into droplets and granulation, laboratory containers, laboratory utensils, etc. The effect of avoiding clogging and saving oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

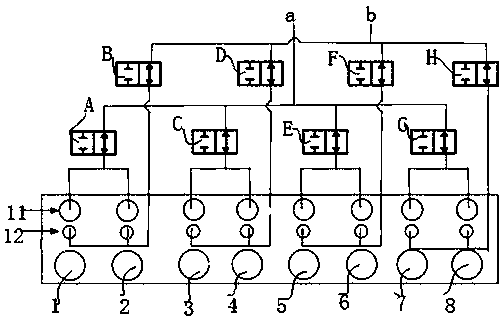

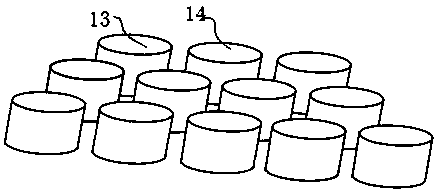

[0029] The present invention discloses a microfluidic chip system that can adjust emulsion formation, combined with Figure 1-Figure 2 As shown, it includes a microfluidic chip and a control mechanism arranged outside the chip. The microfluidic chip is provided with feeding holes and droplet collecting holes. The feeding hole is composed of an oil hole 11 and a sample hole 12, and the oil hole 11 and the sample hole 12 are all communicated with the droplet collection hole through corresponding pipelines, and the inlet ends of the oil hole and the sample hole are respectively provided with Pressure regulator. Due to the use environment and function of the microfluidic chip in the present invention, the pressure adjustment range of the pressure regulating device is 0 psi to 10 psi.

[0030] In the present invention, the feeding holes and droplet collection holes are arranged in parallel on a plane, and there are four groups of feeding holes, each group of feeding holes includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com