Praseodymium samarium thulium-codoped visible laser crystal material preparation method

A laser crystal and co-doping technology, applied in the growth of polycrystalline materials, lasers, crystals, etc., can solve the problems of low repetition frequency, low slope efficiency, difficult to achieve high repetition frequency, high power rate laser output, etc. The effect of high fluorescence efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

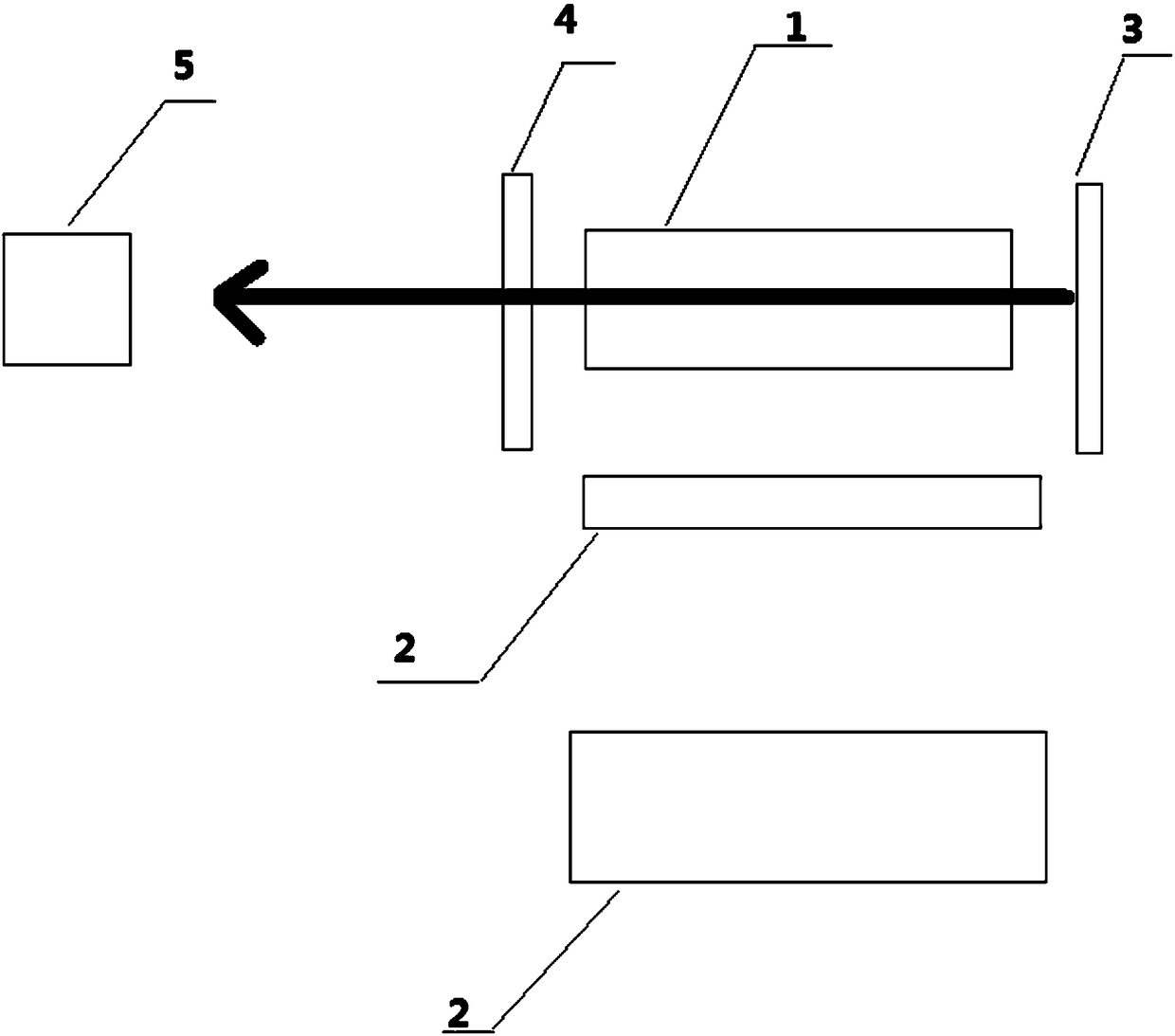

Method used

Image

Examples

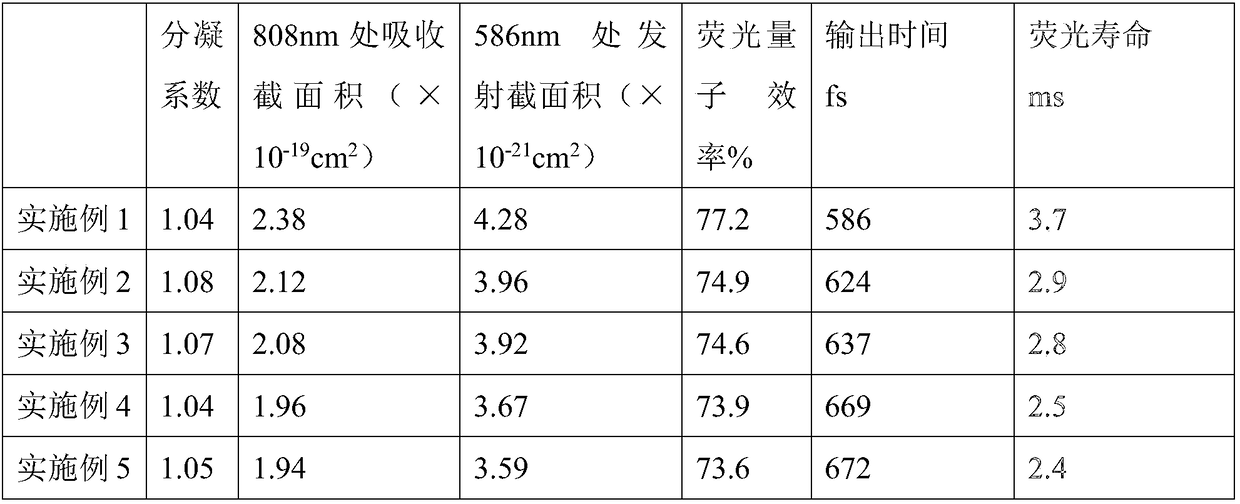

Embodiment 1

[0029] Praseodymium samarium thulium co-doped visible laser crystal material, its chemical formula is: Gd 3-x-y-z SM x PR y T m z sc 2 Ga 3 o 12 ; where x=0.20, y=0.10, z=0.20.

[0030] The preparation method of the praseodymium samarium thulium co-doped visible laser crystal material comprises the following steps:

[0031] (1) Ingredients: according to chemical formula Gd 3-x-y-z SM x PR y T m z sc 2 Ga 3 o 12 Will Gd 2 o 3 、Pr 2 o 3 、Sm 2 o 3 、Tm 2 o 3 、Sc 2 o 3 , Ga 2 o 3 The powder is evenly mixed after weighing according to the molar ratio, and pressed into blocks;

[0032] (2) Sintering: put the block in step (1) into the first crucible, place the first crucible in a sintering furnace, and sinter at 1165°C; the first crucible is an alumina crucible;

[0033] (3) Crystal growth: the sintered material in step (2) is loaded into the second crucible, and the second crucible is placed in the single crystal furnace, and the air in the single crystal f...

Embodiment 2

[0037] Praseodymium samarium thulium co-doped visible laser crystal material, its chemical formula is: Gd 3-x-y-z SM x PR y T m z sc 2 Ga 3 o 12 ; where x=0.3, y=0.05, z=0.23.

[0038] The preparation method of the praseodymium samarium thulium co-doped visible laser crystal material comprises the following steps:

[0039] (1) Ingredients: according to chemical formula Gd 3-x-y-z SM x PR y T m z sc 2 Ga 3 o12 Will Gd 2 o 3 、Pr 2 o 3 、Sm 2 o 3 、Tm 2 o 3 、Sc 2 o 3 , Ga 2 o 3 The powder is evenly mixed after weighing according to the molar ratio, and pressed into blocks;

[0040] (2) Sintering: put the block in step (1) into the first crucible, place the first crucible in a sintering furnace, and sinter at 1150° C.; the first crucible is an alumina crucible;

[0041] (3) Crystal growth: the sintered material in step (2) is loaded into the second crucible, and the second crucible is placed in the single crystal furnace, and the air in the single crystal fu...

Embodiment 3

[0045] Praseodymium samarium thulium co-doped visible laser crystal material, its chemical formula is: Gd 3-x-y-z SM x PR y T m z sc 2 Ga 3 o 12 ; where x=0.1, y=0.15, z=0.15.

[0046] The preparation method of the praseodymium samarium thulium co-doped visible laser crystal material comprises the following steps:

[0047] (1) Ingredients: according to chemical formula Gd 3-x-y-z SM x PR y T m z sc 2 Ga 3 o 12 Will Gd 2 o 3 、Pr 2 o 3 、Sm 2 o 3 、Tm 2 o 3 、Sc 2 o 3 , Ga 2 o 3 The powder is evenly mixed after weighing according to the molar ratio, and pressed into blocks;

[0048] (2) Sintering: put the block in step (1) into the first crucible, place the first crucible in a sintering furnace, and sinter at 1180°C; the first crucible is an alumina crucible;

[0049] (3) Crystal growth: the sintered material in step (2) is loaded into the second crucible, and the second crucible is placed in the single crystal furnace, and the air in the single crystal fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com