A kind of preparation method of fluorosilane surface modified ultrafine ammonium polyphosphate

A technology of ammonium polyphosphate and surface modification, applied in coatings, fireproof coatings, etc., can solve the problems of high energy consumption, complex thermal surface treatment process, selection and treatment process to be studied, etc., to achieve experimental parameter control, surface The effect of simple processing technology and equipment, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Use a supersonic jet mill to crush ammonium polyphosphate into an ultrafine powder with a particle size of 90% ≤ 5 μm;

[0033] (2) Dry the refined powder at a high temperature of 100°C for 12 hours;

[0034] (3) Spray the n-hexane solution of perfluorodecyltriethoxysilane on the surface of ultrafine ammonium polyphosphate powder at a stirring rate of 1500 r / min, wherein the amount of perfluorodecyltriethoxysilane is super 0.5% of the weight of the fine powder, wherein the amount of n-hexane is 4 times that of perfluorodecyltriethoxysilane;

[0035] (4) Mix well and place in an oil bath at 80°C for 2 hours;

[0036] (5) Cooling, crushing, sieving and performance testing.

[0037] The superfine ammonium polyphosphate powder of above-mentioned preparation is carried out performance test, and characterizing result is as follows:

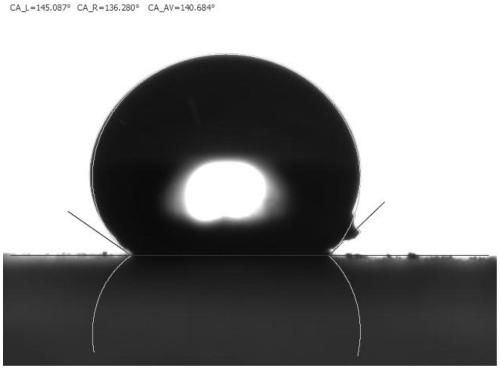

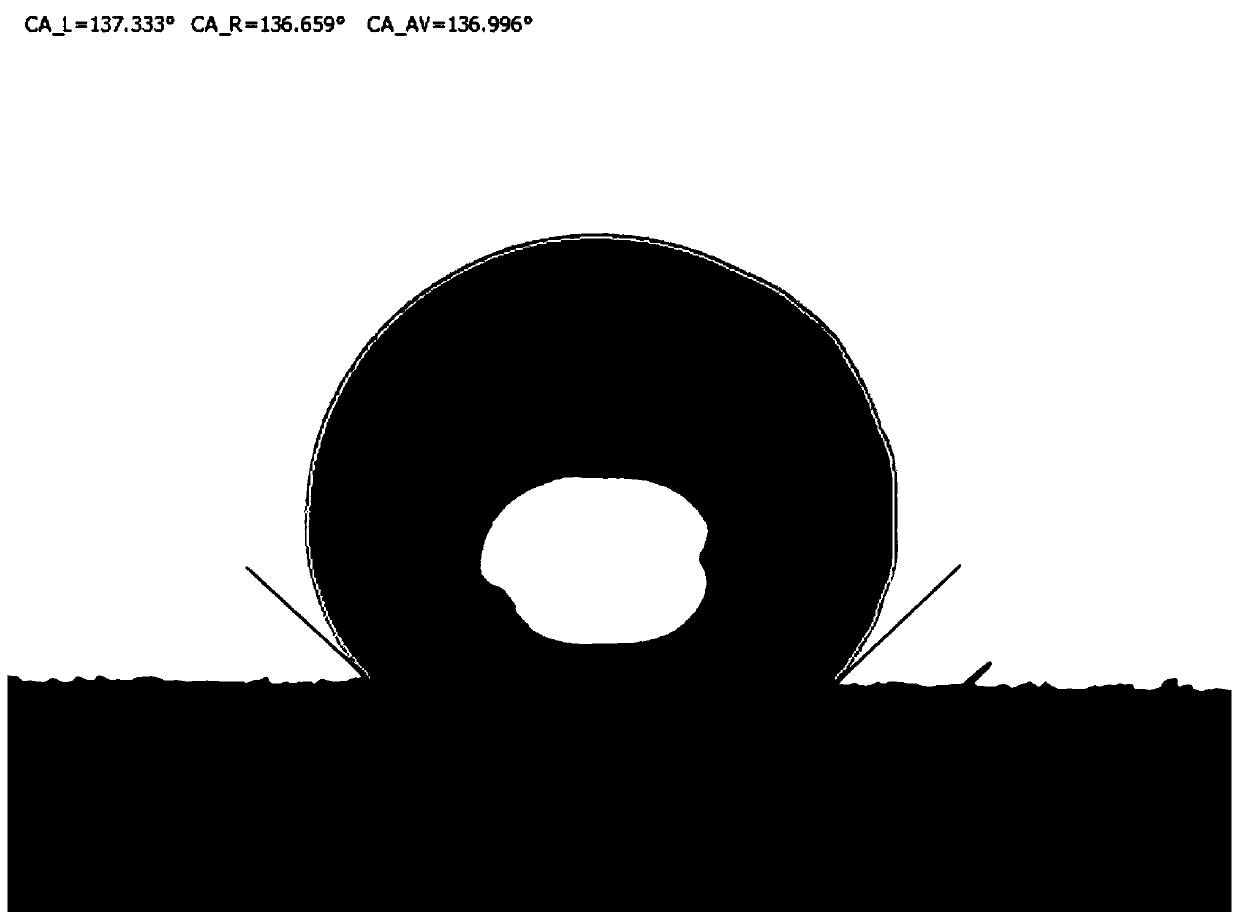

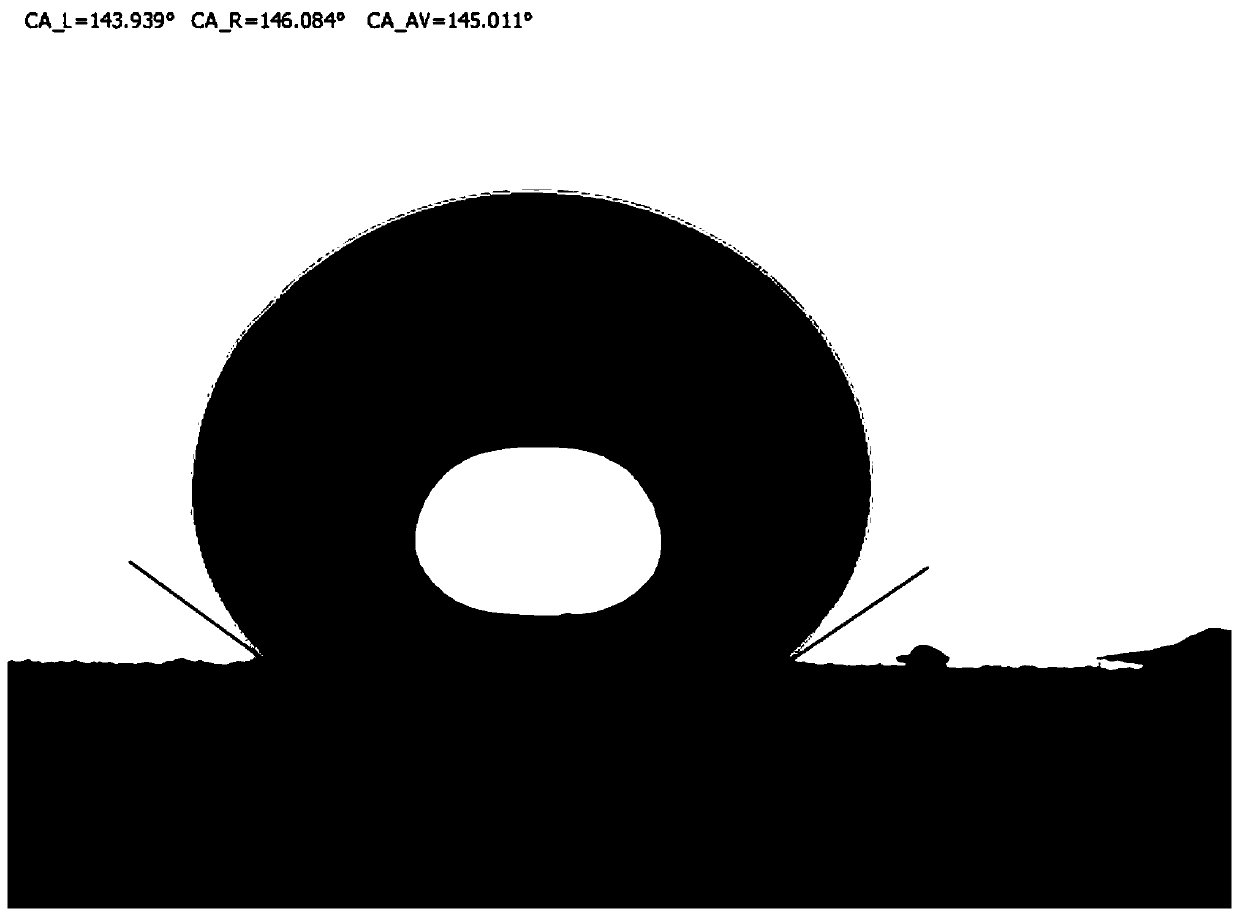

[0038] (1) Use the optical method contact angle / interfacial tension SL200KS contact angle tester authorized by American Kono Industries C...

Embodiment 2

[0041] (1) Use a supersonic jet mill to crush ammonium polyphosphate into an ultrafine powder with a particle size of 90% ≤ 5 μm;

[0042] (2) Dry the refined powder at a high temperature of 110°C for 10 hours;

[0043] (3) Spray the tridecafluorooctyltriethoxysilane isopropanol solution on the surface of the ultrafine ammonium polyphosphate powder at a stirring rate of 1500 r / min, in which the tridecafluorooctyltriethoxysilane The amount is 3% of the weight of the ultrafine powder, and the amount of isopropanol is 5 times that of tridecafluorooctyltriethoxysilane;

[0044] (4) Mix well and place in an oil bath at 110°C for 1 hour;

[0045](5) Cooling, crushing, sieving and performance testing.

[0046] The superfine ammonium polyphosphate powder of above-mentioned preparation is carried out performance test, and characterizing result is as follows:

[0047] (1) Use the optical method contact angle / interfacial tension SL200KS contact angle tester authorized by American Kono...

Embodiment 3

[0050] (1) Use a supersonic jet mill to crush ammonium polyphosphate into an ultrafine powder with a particle size of 90% ≤ 5 μm;

[0051] (2) Dry the refined powder at a high temperature of 110°C for 10 hours;

[0052] (3) Spray the perfluorodecyltriethoxysilane acetone solution on the surface of the ultrafine ammonium polyphosphate powder at a stirring rate of 1000 r / min, wherein the amount of perfluorodecyltriethoxysilane is ultrafine 5% of the weight of the powder, where the amount of acetone is 6 times that of perfluorodecyltriethoxysilane;

[0053] (4) Mix well and place in an oil bath at 90°C for 1.5 hours;

[0054] (5) Cooling, crushing, sieving and performance testing.

[0055] The superfine ammonium polyphosphate powder of above-mentioned preparation is carried out performance test, and characterizing result is as follows:

[0056] (1) Use the optical method contact angle / interfacial tension SL200KS contact angle tester authorized by the American Kono Industry Co....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com