Experimental device for simulating erosion and wear of ball-pitching sleeve

A ball-throwing sliding sleeve and experimental device technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems of seat seal failure, erosion and wear of downhole hydraulic sandblasting tools, etc., and achieve the effect of controllable experimental parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

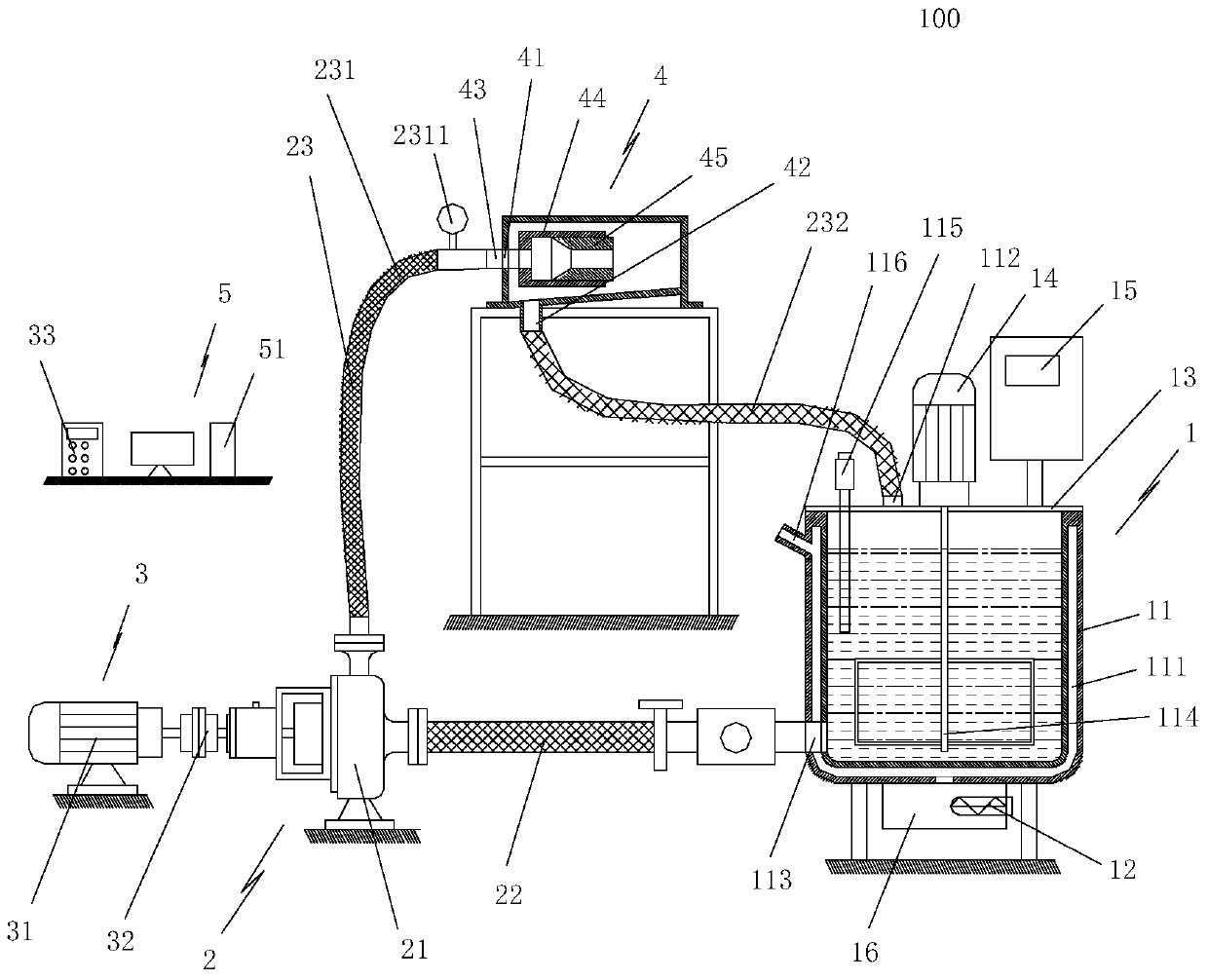

[0034] Such as figure 1 As shown, the present invention proposes an experimental device 100 for simulating the erosion and wear of a pitching sleeve. The experimental device 100 includes a mortar heating and mixing device 1, a mortar circulation system 2, a power system 3, a visual specimen erosion chamber 4, and a data Processing system 5; the mortar heating and mixing device 1 includes a barrel body 11 with a hollow interlayer 111, the interlayer 111 of the barrel body is provided with a heat-conducting medium (heat-conducting oil or water), and the heat-conducting medium is heated by an electric heater 12; The barrel body 11 is equipped with mortar and is provided with a mortar inlet 112 and a mortar outlet 113, and the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com