Method and device for evaluating desulfurization and denitrification performance of active coke

A technology for desulfurization and denitrification and evaluation methods, which is applied in the field of evaluation methods and devices for desulfurization and denitrification performance of active coke, can solve problems such as complex processes, poor accuracy, and large detection errors, and achieve rigorous and accurate detection and analysis, avoid detection errors, and be accurate The effect of performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

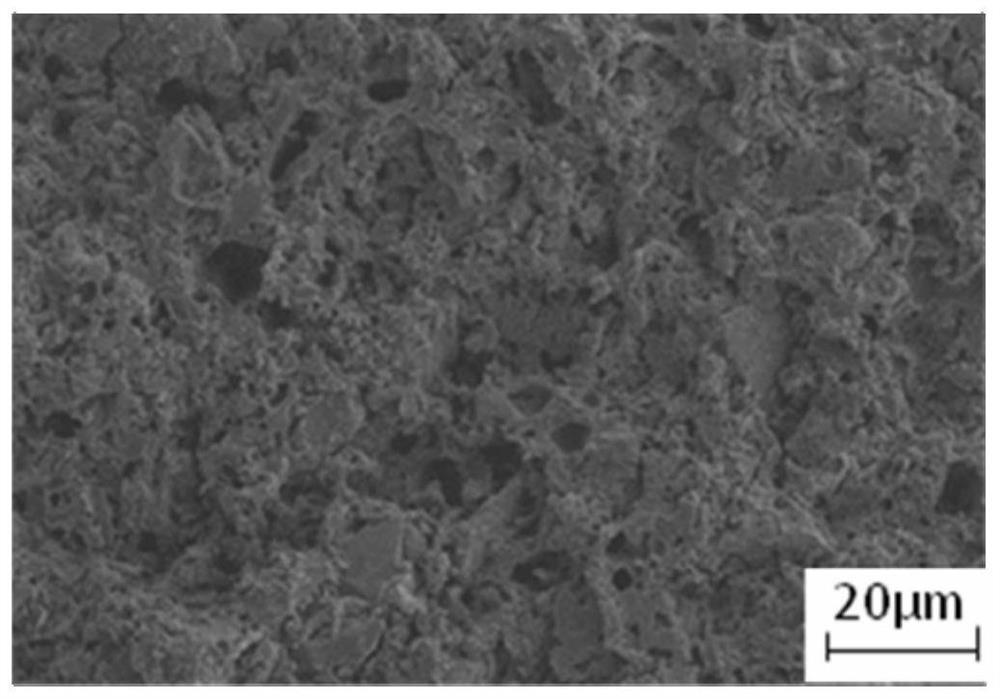

[0129] In this embodiment, sample 1 (as-received active coke, primary adsorption tower, secondary adsorption tower, and desorption tower) and sample 2 (as-received active coke, primary adsorption tower, secondary adsorption tower, and desorption tower) were selected to detect and analyze the activity Coke pore structure parameters, pore size distribution, surface microstructure, phase composition, and functional groups.

[0130] The process is as follows:

[0131] 1. Active coke sample pretreatment

[0132] Weigh 40g of the active coke sample, put it evenly in the crucible, place the crucible containing the active coke sample in the middle of the microwave equipment, and treat the active coke sample for 10min at a microwave power of 1000W to pretreat the active coke sample to improve its desulfurization and denitrification. performance.

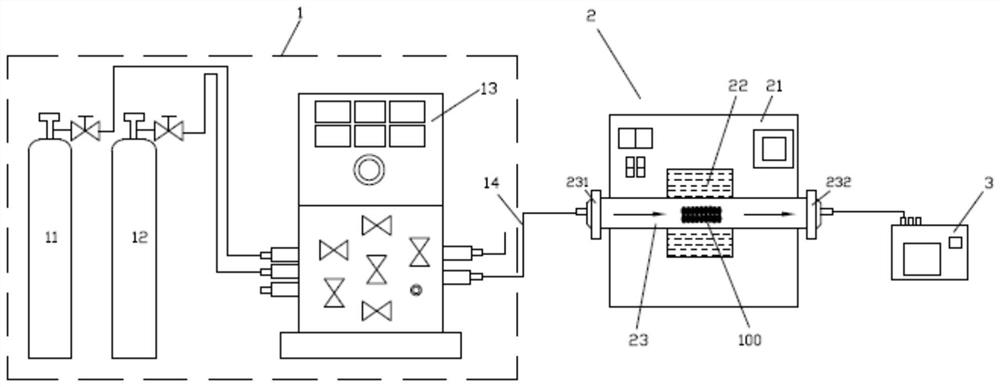

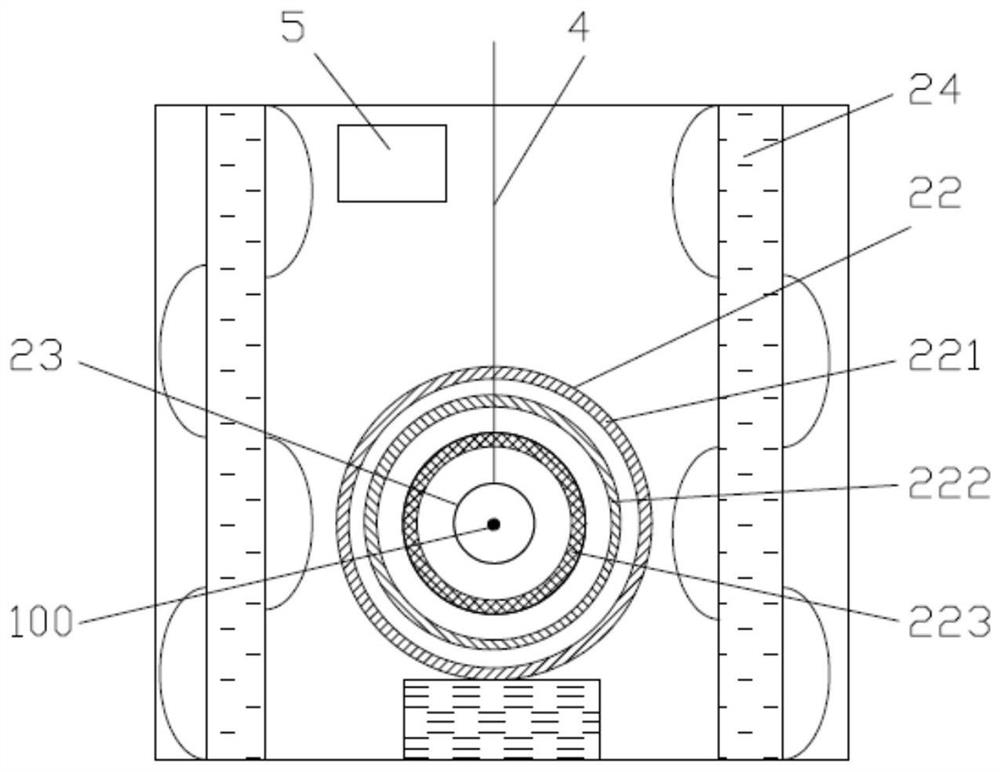

[0133] 2. Activated coke desulfurization and denitrification simulation experiment

[0134] The parameters were set according to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com