Nitrogen-doped titania/silica photocatalytic coating supported by diatomite

A technology of diatomite and photocatalysis, applied in physical/chemical process catalysts, chemical/physical processes, coatings, etc., can solve the problems of poor dispersion and low efficiency of decomposing harmful gases in the room, and achieve improved dispersion and degradation process Irreversible, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

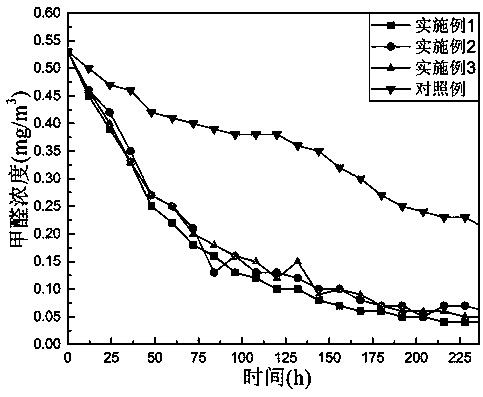

Embodiment 1

[0030] A diatomaceous earth loaded N-TiO 2 / SiO 2 Photocatalytic coating, in parts by weight, its raw material composition is: 25 parts of water, diatomaceous earth load N-TiO 2 / SiO 2 18 parts, Ca(OH) 2 2.5 parts, wollastonite powder 7.5 parts, redispersible rubber powder 2.5 parts, bentonite 2.5 parts, dispersant 1.5 parts, curing agent 1 part, defoamer 0.8 parts.

[0031] The diatomaceous earth supported N-TiO 2 / SiO 2 Preparation of:

[0032] (1) Dissolve 3ml of titanium isopropoxide in 21ml of ethylene glycol and stir magnetically for 4 hours to obtain solution A; mix 0.5g of cetyltrimethylammonium bromide, 0.25g of urea, 15ml of 5mol / L nitric acid solution, 2.5 Dissolve ml tetraethyl orthosilicate in ethanol, and stir magnetically for 30 minutes to obtain solution B; drop solution A into solution B and mix evenly, then transfer it to a stainless steel hydrothermal synthesis reactor with a polytetrafluoroethylene liner and react at 150°C for 10 hours After cooling ...

Embodiment 2

[0037] A diatomaceous earth loaded N-TiO 2 / SiO 2 The photocatalytic coating, in parts by weight, consists of raw materials: 30 parts of water, diatomaceous earth loaded N-TiO 2 / SiO 2 16 parts, Ca(OH) 2 2.5 parts, 2.5 parts of redispersible rubber powder, 7.5 parts of wollastonite powder, 2.5 parts of bentonite, 1 part of dispersant, 1 part of curing agent, and 0.8 part of defoamer.

[0038] The diatomaceous earth supported N-TiO 2 / SiO 2 Preparation of:

[0039] (1) Dissolve 3ml of titanium isopropoxide in 21ml of ethylene glycol and stir magnetically for 4 hours to obtain solution A; mix 0.5g of cetyltrimethylammonium bromide, 0.25g of urea, 15ml of 5mol / L nitric acid solution, 2.5 Dissolve ml tetraethyl orthosilicate in ethanol, and stir magnetically for 30 minutes to obtain solution B; drop solution A into solution B and mix evenly, then transfer it to a stainless steel hydrothermal synthesis reactor with a polytetrafluoroethylene liner and react at 130°C for 10 hou...

Embodiment 3

[0044] A diatomaceous earth loaded N-TiO 2 / SiO 2 Photocatalytic coating, in parts by weight, its raw material composition is: 25 parts of water, diatomaceous earth load N-TiO 2 / SiO 2 20 parts, wollastonite powder 7.5 parts, Ca(OH) 2 2.5 parts, 2 parts of redispersible rubber powder, 2.5 parts of bentonite, 1.5 parts of dispersant, 1 part of curing agent, 0.8 part of defoamer.

[0045] The diatomaceous earth supported N-TiO 2 / SiO 2 Preparation of:

[0046] (1) Dissolve 3ml of titanium isopropoxide in 21ml of ethylene glycol and stir magnetically for 4 hours to obtain solution A; mix 0.5g of cetyltrimethylammonium bromide, 0.8ml of ammonia water, 15ml of 5mol / L nitric acid solution, 3ml Dissolve ethyl orthosilicate in ethanol, and stir magnetically for 30 minutes to obtain solution B; drop solution A into solution B and mix evenly, then transfer it to a stainless steel hydrothermal synthesis reactor with a polytetrafluoroethylene liner and react at 170°C for 10 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com