A large cone twin extruder foaming screw

A technology of extruder and screw, which is applied in the field of foaming screw of large conical double extruder, which can solve the problem that the output of the extruder cannot meet the requirements of the market, and achieve the effects of shortening the heat conduction distance, improving efficiency and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

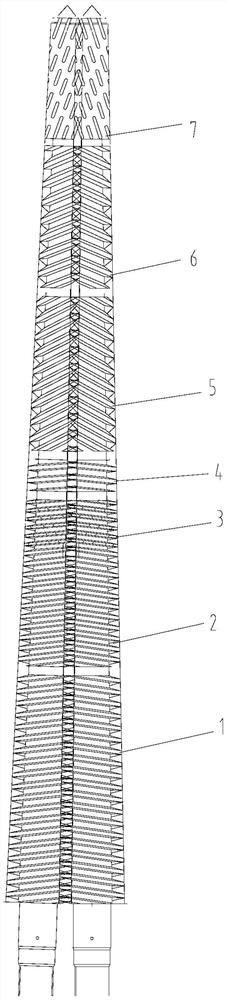

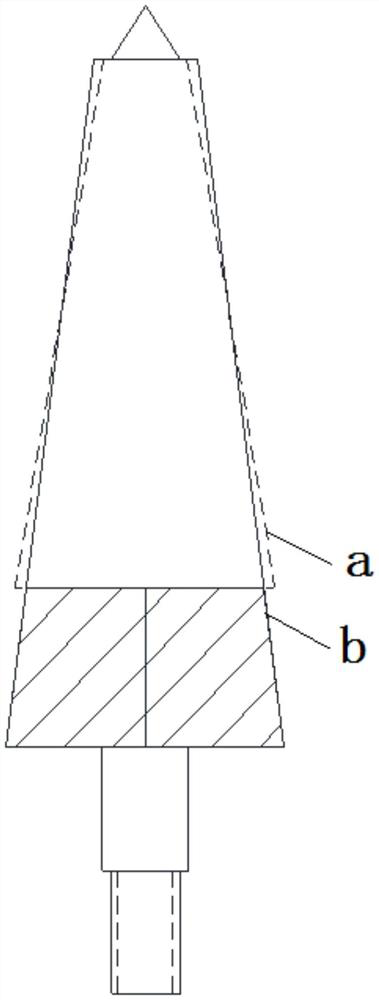

[0031] A large extruder foaming cone twin screw, such as figure 1 As shown, it consists of left screw and right screw, including feeding section 1, compression section 3, metering section 4, exhaust section 5 and mixing section 6, and also includes pre-compression section 2 and dynamic mixing head 7, pre-compression section 2 is set between the feeding section 1 and the compression section 2, the dynamic mixing head 7 is set at the end of the mixing section 6, the left screw and the right screw are in the feeding section 1, pre-compression section 2, compression section 3, metering section 4 , The exhaust section 5 and the mixing section 6 are provided with screw ribs 10 that mesh with each other, and screw grooves 9 are formed between adjacent screw ribs 10 (refer to Figure 4 ), the width of the screw groove 9 is the pitch, and the dynamic mixing head 7 is provided with mutually engaging bumps 8 (refer to image 3 ), the bumps 8 are long blocks, the bumps 8 are arranged in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com