A preparation method and application of fermented iris extract for tobacco

The technology of extract and iris, which is applied in the field of preparation of iris extract for fermented tobacco, can solve the problems of masking characteristic aroma, high production cost, high irritation, etc., and achieve the effects of reduced irritation, less impurities and low irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

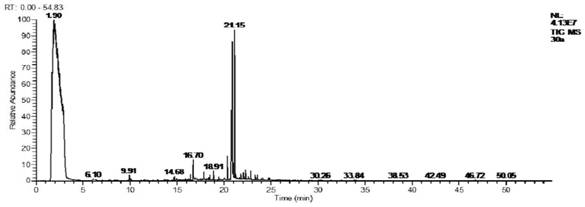

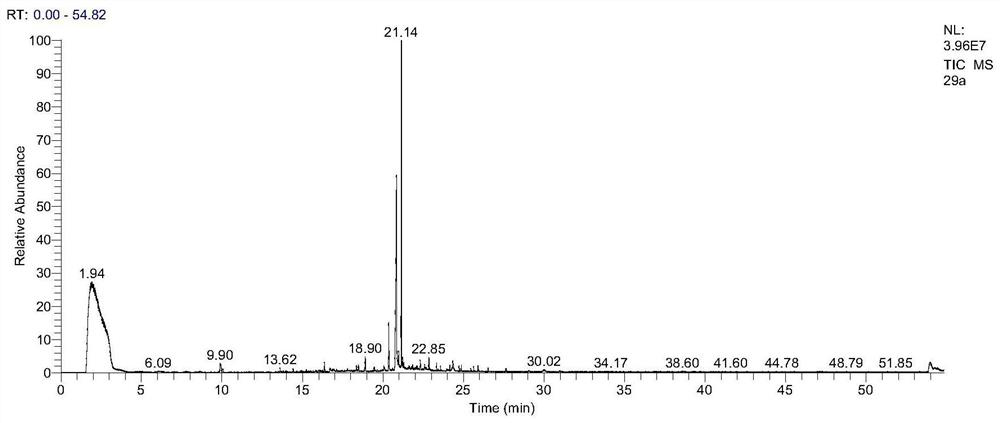

Image

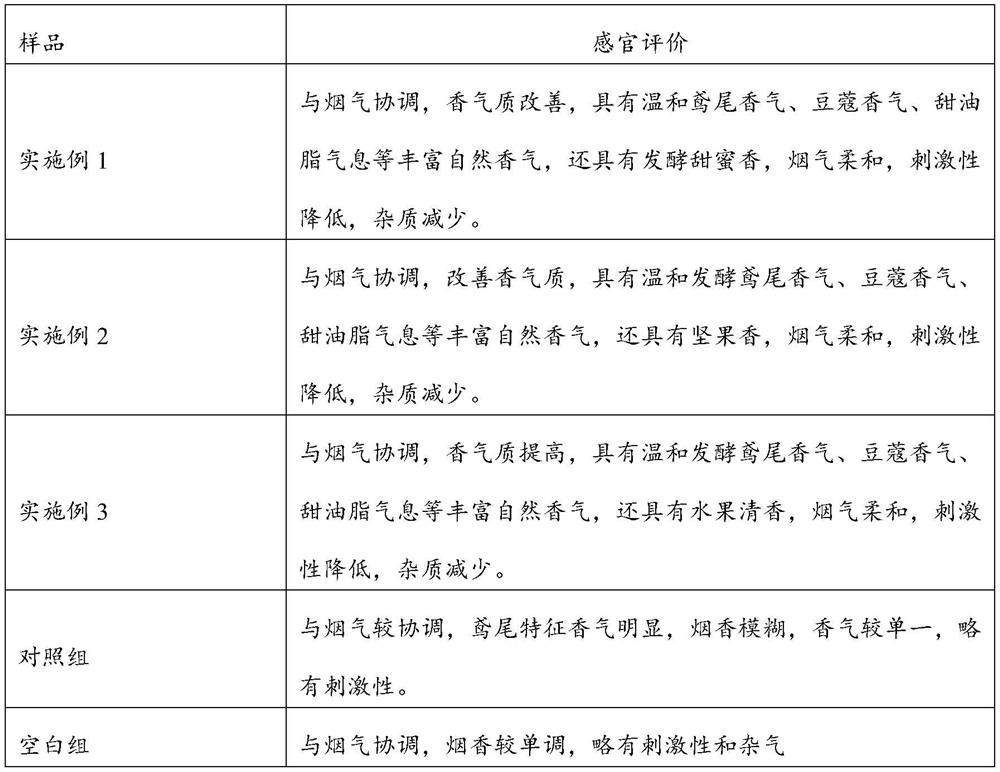

Examples

Embodiment 1

[0027] A preparation method of fermented iris extract for tobacco, comprising the steps of:

[0028] (1) Slicing crushing and incubation and fermentation: Grinding orris root slices to 40 mesh, mixing with water evenly at a mass ratio of 1:10, 30KHz frequency ultrasonic assistance for 30min, adding succinic acid and benzoic acid (food grade, accounting for the mass of iris powder 0.1% of Lactococcus lactis (Lactococcus lactis subsp. lactis) (food grade, enzyme activities are respectively 500u / g, 5000u / g, 5000u / g and 2000u / ml, according to the mass ratio of 0.3% of the iris raw material, the proportion is 1:0.5:0.8:0.8 according to the mass ratio), heated to 35°C and stirred evenly, incubated and fermented 18h, obtain the iris fermented liquid;

[0029] (2) Soxhlet extraction, extraction purification and microwave spray drying: the iris fermented liquid was dried by microwave spraying to obtain the fermented product of iris, which was put into a microfiltration bag (pore size:...

Embodiment 2

[0034] A preparation method of fermented iris extract for tobacco, comprising the steps of:

[0035](1) Slicing crushing and incubation and fermentation: Grinding orris root slices to 100 mesh, mixing with water evenly at a mass ratio of 1:25, assisted by 60KHz frequency ultrasound for 24min, adding succinic acid, benzoic acid, oxalic acid (food grade, accounting for iris The mass ratio is 0.5%, and the proportion is 1:0.6:1.0), adding compound biological agent β-glucosidase, pullulanase, dextranase and Lactococcus lactis subsp.lactis (food grade, enzyme Activity is respectively 5000u / g, 10000u / g, 10000u / g and 5000u / ml, by 0.2% of the raw material mass ratio of iris, the proportioning ratio between biological preparations is 1:0.5:2:0.5 by mass ratio), heated to Stir at a constant speed at 45°C, incubate and ferment for 36 hours, and obtain the iris fermentation liquid;

[0036] (2) Soxhlet extraction, extraction purification and microwave spray drying: the iris fermented liq...

Embodiment 3

[0041] A preparation method of fermented iris extract for tobacco, comprising the steps of:

[0042] (1) Slicing crushing and incubation and fermentation: Grinding orris root slices to 200 mesh, mixing with water evenly at a mass ratio of 1:50, 100KHz frequency ultrasonic assistance for 15min, adding succinic acid, benzoic acid, oxalic acid (food grade, accounting for iris The mass ratio is 1%, and the mass ratio of the three is 1:2:0.5), adding compound biological agent β-glucosidase, pullulanase, dextranase and Lactococcus lactis milk subspecies (Lactococcuslactis subsp.lactis) (food Grade, enzyme activities are 10000u / g, 40000u / g, 50000u / g and 10000u / ml respectively, according to 0.1% of the mass ratio of iris raw materials, the ratio between biological preparations is 1:0.6:1.2:1.5 by mass ratio) , heat and stir evenly, incubate at 45°C for 36 hours, then raise the temperature to 55°C for 36 hours to obtain the iris fermentation liquid;

[0043] (2) Soxhlet extraction, ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com