Preparation process of protein hydrolysate and application of protein hydrolysate to fermentation culture

A technology of proteolysis and preparation process, which is applied in the field of preparation process and its application in fermentation culture, and can solve the problem of high protein ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation technology of proteolysis liquid, it comprises the steps:

[0030] Mix soybean meal and water at a mass ratio of 1:1, steam-treat at 121°C for 10 minutes, and then naturally cool to room temperature to obtain a soybean meal culture solution;

[0031] Bacillus licheniformis, Cellulomonas flavinogenes, Aspergillus niger and Aspergillus oryzae were cultured according to routine to obtain seed liquid;

[0032] Bacillus licheniformis seed liquid, Cellulomonas flavinogenes seed liquid, Aspergillus niger seed liquid and Aspergillus oryzae seed liquid are mixed according to the volume ratio of 2:2:1:1, obtain mixed seed liquid; Then mix seed liquid according to 10 % of the inoculum was inserted into a fermentation tank containing soybean meal culture liquid for fermentation and enzyme production. The temperature was 35°C, the tank pressure was 0.03MPa, the air volume was 500L / h, and the fermentation time for enzyme production was 60h. Ultrasonic treatment was pe...

Embodiment 2

[0038] The components of soybean meal produced by various soybean species are not very different. The present invention selects the soybean meal with skin, and the contents of each main component are: protein 45%, ash content 7%, fiber 20%, moisture 10%, fat 2%, carbohydrate 14%, the others are inorganic minerals.

[0039] Main index detection method: Kjeldahl method for determination of total protein; SDS-PAGE for differential determination of protein molecular weight; determination of reducing sugar content: direct titration method, referring to GB / T5009.7-2008; routine HPLC detection of free amino acids, oligosaccharides Peptide and polypeptide content; Determination of degree of protein hydrolysis using ninhydrin chromogenic method to determine the degree of hydrolysis.

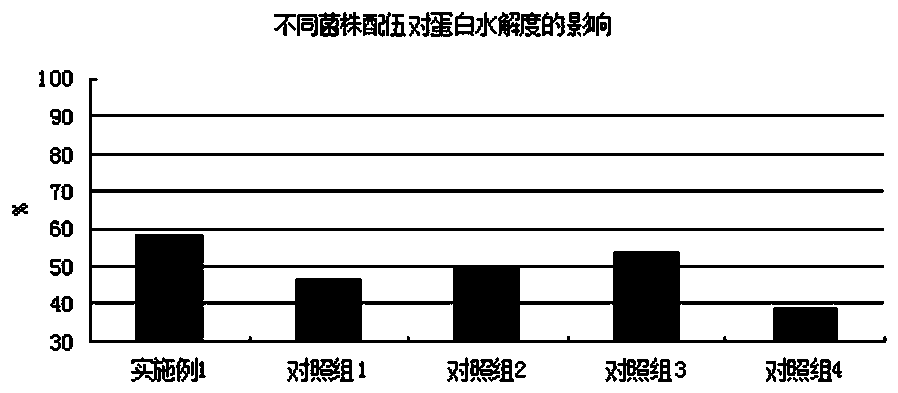

[0040] Set up the compatibility effect of each bacterial strain of group verification, wherein, control group 1 is Bacillus licheniformis, Cellulomonas xanthogenes and Aspergillus oryzae three kinds of ba...

Embodiment 3

[0046] The enzymolysis solution prepared in Example 1 was concentrated and then spray-dried to obtain a dry powder (experimental group), which was used to replace the yeast powder in the YPD medium (control group), and the remaining components were kept unchanged. Saccharomyces cerevisiae was cultivated under the same conditions. The growth situation evaluates the cultivation effect of the product, see Table 2 for details.

[0047] Table 2

[0048] Saccharomyces cerevisiae cultured for 12 hours (OD 600 )

[0049] As shown in Table 3, compared with commercially available yeast powder, the dry powder prepared by the present invention has better cultivation in cultured yeast, and can be used as a substitute for commercially available yeast powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com