Chip employing liquid metal for enhancing inner heat transmission

A liquid metal and chip technology, applied in semiconductor/solid device components, electrical components, electrical solid devices, etc., can solve the problems of large thermal resistance, narrow heat transfer path of chips, etc., and achieve high-efficiency heat dissipation and less heat transfer Thermal resistance, the effect of enhancing heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

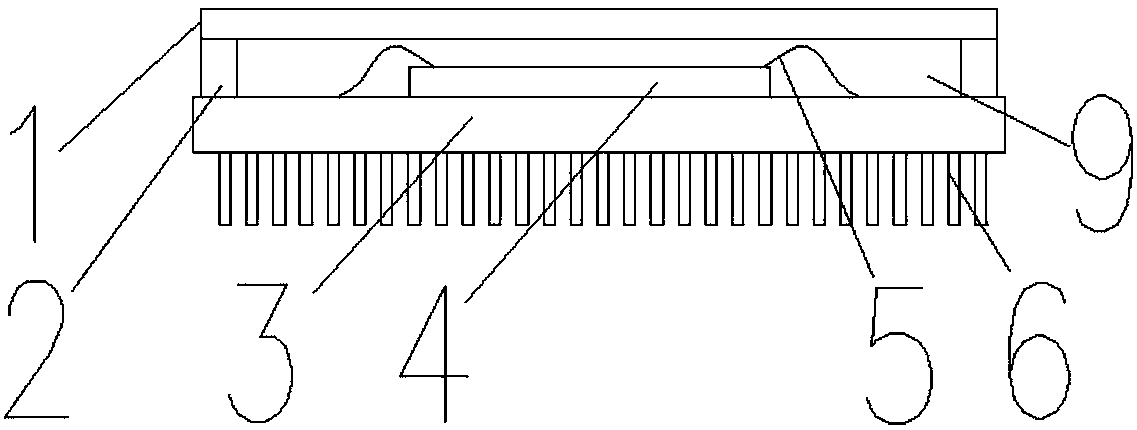

[0019] Nitrogen 9 is poured into the cavity of the traditional ceramic chip package, and the heat dissipation effect is very poor. The heat generated by the silicon chip is mainly transmitted to the sealing ring 2 through the substrate, and then to the cover through the very small contact area between the sealing ring 2 and the cover plate 1. 1 is lost to the outside world, the heat transfer path of the chip is narrow, the thermal resistance is large, and the heat dissipation performance is poor.

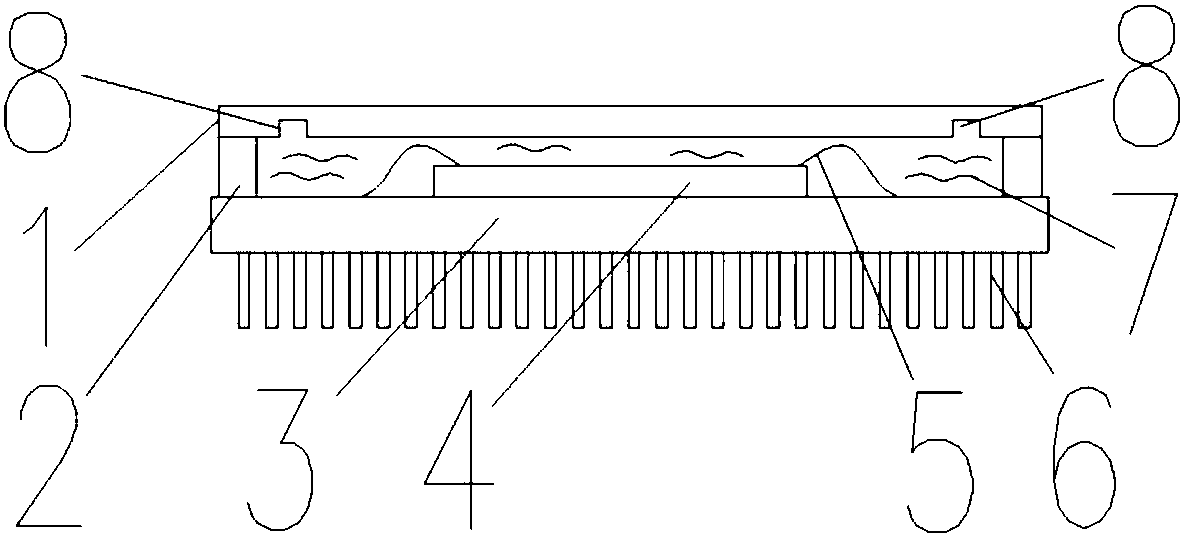

[0020] The present invention fills the cavity of the ceramic chip with the liquid metal 7, increases the heat transfer path, reduces the internal thermal resistance of the chip, and improves the heat dissipation performance of the chip.

[0021] Common liquid metals such as mercury, but due to its toxicity, cannot be selected in the chip, due to the liquid gallium metal 7 alloy, which has high thermal conductivity and low melting point. For example, GaIn15Sn13Zn1 has a low melting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com