Three-dimensional hollow structure heat collecting evaporation fabric and preparation and using methods and application thereof

A three-dimensional hollow, heat-collecting technology, applied in fabrics, multi-strand fabrics, textiles, and papermaking, can solve the problems of high device cost, low water recovery rate, and low desalination efficiency, and achieve high water evaporation efficiency and good heat insulation and water conductivity, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Three-dimensional hollow structure heat collecting and evaporating fabric of cotton fiber

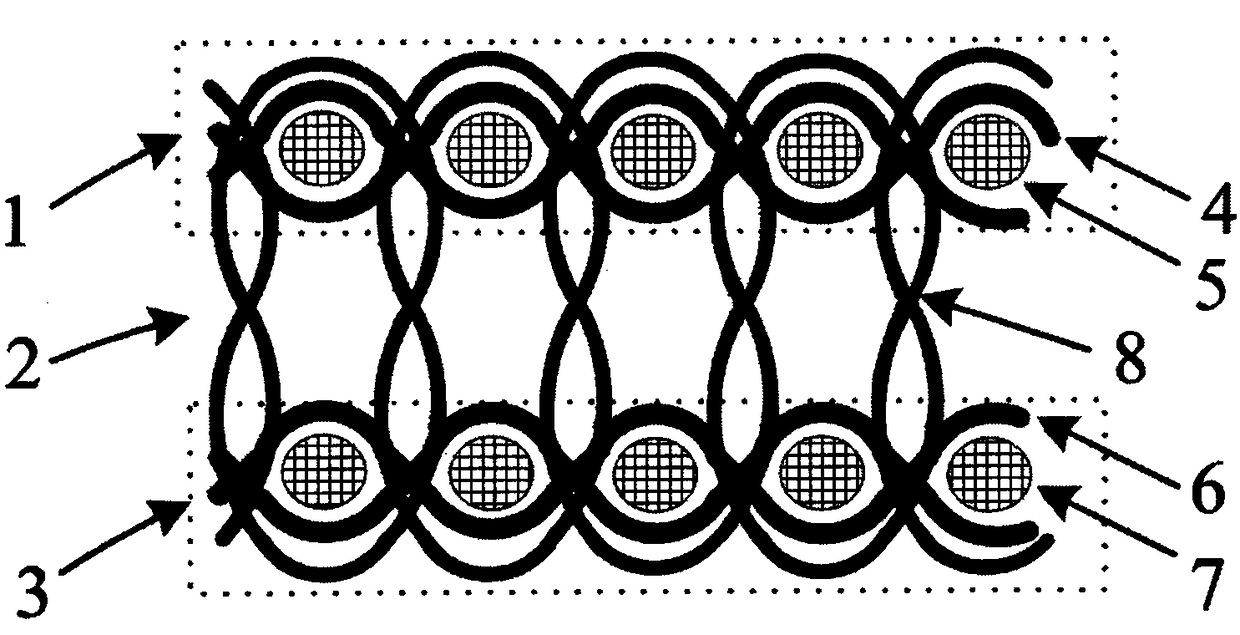

[0035] combine figure 1 , select the polyethylene fiber of 1000tex as F layer warp yarn (floating layer warp yarn 6) and lower floor weft yarn (floating layer weft yarn 7) to weave floating layer 3; Select 20 cotton yarns as hydrophilic fiber and 100D polyester monofilament as supporting fiber, Arranged at intervals and mixed as spacer yarns 8 to weave the heat-insulating and water-conducting layer 2, the fiber root ratio is 1:1; 20 black cotton fibers are selected for air deformation as the upper warp yarn (warp yarn 4 of the heat-collecting and evaporation layer) and the upper weft yarn (collecting and evaporating layer warp yarn 4). The heat evaporation layer weft yarn 5) weaves the heat collection evaporation layer 1. Set fabric width to 10 cm, warp and weft density: 15 threads / cm; spacer yarn density: 15 threads / cm;

[0036] Weaving process: the first step is to activate t...

Embodiment 2

[0038] Three-dimensional hollow structure heat collecting and evaporating fabric of polyester fiber

[0039] The polyethylene fiber of 600tex is selected as the lower warp yarn, and the polypropylene plastic tube (hollowness 80%) closed at both ends with a diameter of 4 mm is used as the weft yarn to weave the floating layer; 1000tex hydrophilic modified polyester bulked yarn is selected as the hydrophilic fiber and 150D The polypropylene monofilament is used as the supporting fiber, which is arranged at intervals and mixed as the spacer yarn to weave the heat-insulating and water-conducting layer, and the fiber root ratio is 1:1; the black 1000tex hydrophilic modified polyester fiber is used as the upper warp yarn and the upper weft yarn weaving set thermally evaporated layer. Set fabric width to 10 cm, warp and weft density: 12 threads / cm; interval yarn density: 12 threads / cm;

[0040] Weaving process: the first step is to activate the weft insertion device to introduce the...

Embodiment 3

[0042] Polypropylene fiber three-dimensional hollow structure heat collection and evaporation fabric

[0043] Use 1000tex polyethylene fiber as the lower warp yarn and lower weft yarn to weave the floating layer; use 1000tex hydrophilic modified polypropylene bulky yarn as the hydrophilic fiber and 150D polypropylene monofilament as the supporting fiber, and arrange them at intervals and mix them as spacer yarns for weaving The thermal insulation and water-conducting layer has a fiber ratio of 1:1; black 1000tex hydrophilic modified polypropylene fiber is selected as the upper warp yarn and the upper weft yarn to weave the heat-collecting evaporation layer. Set fabric width to 10 cm, warp and weft density: 10 threads / cm; spacer yarn density: 10 threads / cm;

[0044] Weaving process: the first step is to activate the weft insertion device to introduce the weft yarns of the upper and lower layers; the second step is to drive the upper and lower warp yarns to interweave synchronousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com