A two-stage thermal desorption system for oil sludge with high water content and its integrated skid

A high water content, thermal desorption technology, applied in water/sludge/sewage treatment, sludge treatment, lighting and heating equipment, etc. To achieve the effect of increasing partition and high temperature flue gas turbulence, improving energy utilization efficiency, and increasing water evaporation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] When used as a system alone (not limited to skid-mounted systems):

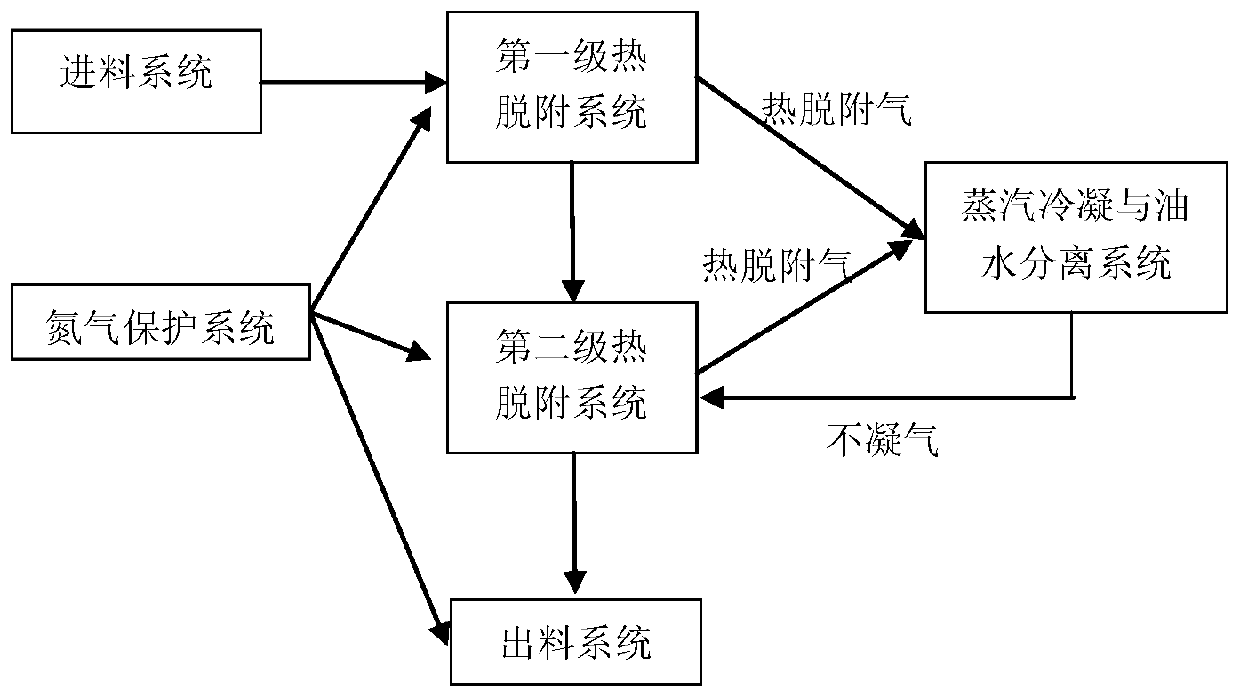

[0063] Including feed system 1, first-stage thermal desorption system 4, second-stage thermal desorption system 24, discharge system, steam condensation and oil-water separation system 11, nitrogen protection system:

[0064] The feeding system 1 is sequentially composed of a screw pump, a drum screening machine, a feeding hopper, a belt scale, and a scraper conveyor.

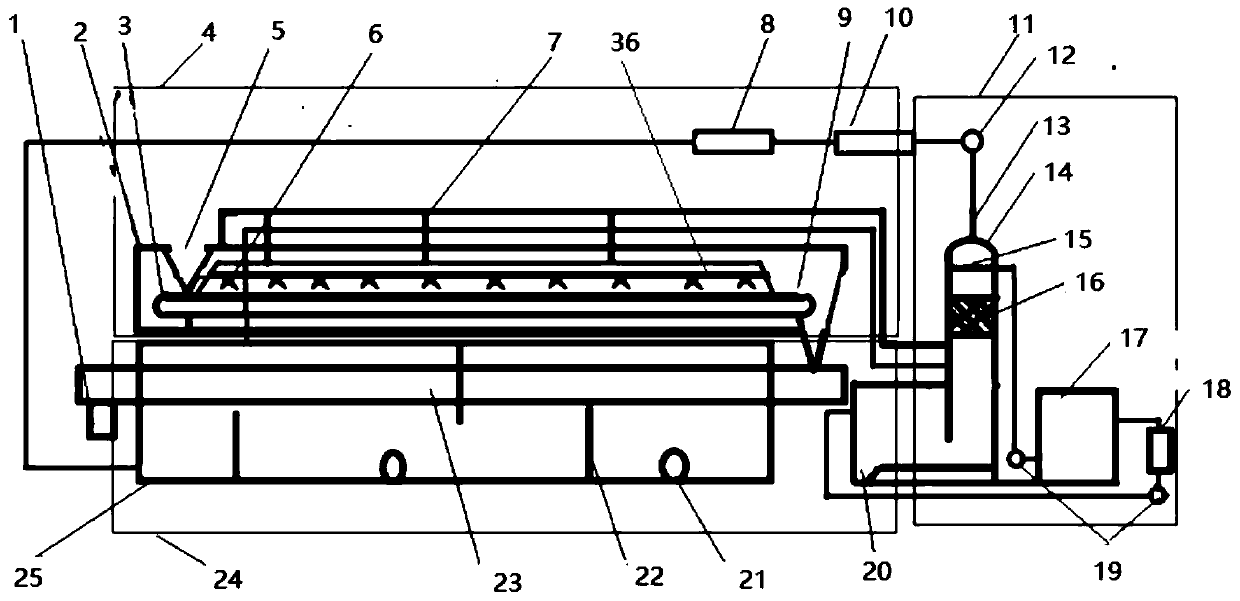

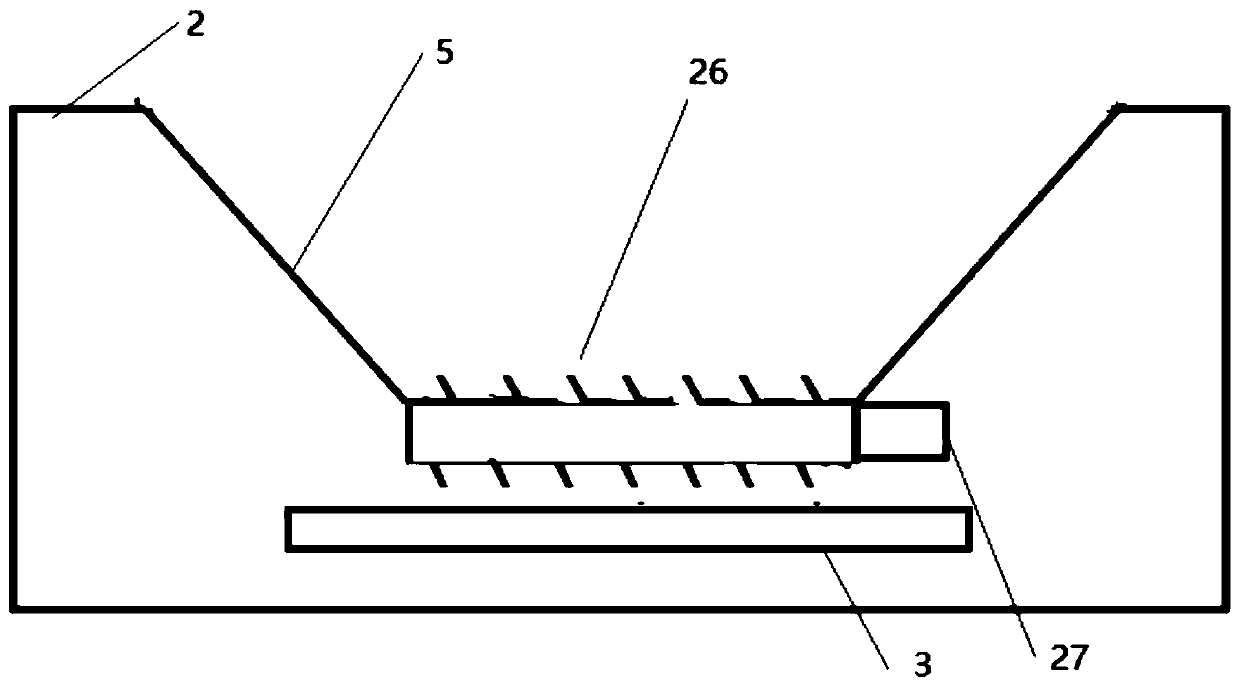

[0065] The first-stage thermal desorption system 4 is composed of a feed inlet 5, a microwave generation system 6, a transmission belt 3, a first steam recovery pipeline, and a second steam recovery pipeline (the first steam recovery pipeline and the second steam recovery pipeline jointly form the first Stage thermal desorption gas recovery pipeline 7) and microwave protection cover 2; The upper part, the upper end of the feeding port 5 is sealed and connected with the upper part of the microwave protection cover 2, one end of the tran...

Embodiment 2

[0079] When a two-stage thermal desorption system for oil sludge with high water content is integrated into the skid-mounted system and used as a skid-mounted integrated two-stage thermal desorption system for oil sludge with high water content, it mainly includes feed skid 1, thermal desorption Skid, discharge skid, steam condensation and oil-water separation skid 11, nitrogen protection skid, of which the thermal desorption skid is divided into upper skid and lower skid, the upper skid is the first-level thermal desorption skid 4, and the lower skid is the second-level thermal desorption skid. Detach skid 24; It is characterized in that:

[0080] The feeding skid is composed of screw pump, drum screening machine, feeding hopper, belt scale and scraper conveyor in sequence.

[0081] The upper skid is composed of feed inlet 5, microwave generation system 6, transmission belt 3, first steam recovery pipeline, second steam recovery pipeline, and microwave protection cover 2; the...

Embodiment 3

[0098] The use process of the present invention is as follows (taking the integrated skid as an example):

[0099] When the present invention is set, when the station is fixed, according to the feed system 1, the first-stage thermal desorption system 4, the second-stage thermal desorption system 24, the discharge system, the steam condensation and oil-water separation system 11, and the nitrogen protection system For installation and connection; during temporary construction, according to feeding skid 1, thermal desorption skid, discharge skid, steam condensation and oil-water separation skid 11, nitrogen protection skid, among which thermal desorption skid is divided into upper skid and lower skid, and upper skid The first-stage thermal desorption skid 4 and the lower skid are the second-stage thermal desorption skid 24 for installation and connection.

[0100] Take the implementation process of the two-stage thermal desorption skid-mounted device for sludge with high moistur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com