Co3O4 nanosheet-loaded stainless steel mesh as well as preparation method and application thereof

A stainless steel mesh and nanosheet technology is applied in the field of Co3O4 nanosheet supported stainless steel mesh and its preparation, which can solve the problems of high cost, low photothermal conversion efficiency, complicated preparation process, etc. The effect of good conversion characteristics and high water evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a Co 3 o 4 The preparation method of nanosheet-loaded stainless steel mesh specifically comprises the following steps:

[0043] Step 1. Stainless steel mesh pretreatment

[0044] Step 11, take 120-400 mesh 304 stainless steel mesh, and cut the stainless steel mesh into a square structure of 40mm×40mm;

[0045] Step 12, immerse the square stainless steel mesh in step 11 into acetone, and ultrasonically clean it to remove organic impurities on the surface of the stainless steel mesh to obtain a stainless steel mesh that removes organic impurities; wherein, the ultrasonic cleaning time is 20-30min, and the ultrasonic power is 100 -120W;

[0046] Step 13, immerse the stainless steel mesh from which organic impurities have been removed in a hydrochloric acid solution, and perform ultrasonic cleaning to remove oxide impurities on the surface of the stainless steel mesh to obtain a stainless steel mesh from which oxides have been removed; wherein, the...

Embodiment 1

[0058] Embodiment 1 provides a Co 3 o 4 The preparation method of nanosheet-loaded stainless steel mesh specifically comprises the following steps:

[0059] Step 1. Stainless steel mesh pretreatment

[0060] Step 11, take 120-mesh 304 stainless steel mesh, and cut the stainless steel mesh into a square structure of 40mm×40mm;

[0061] Step 12, immerse the square stainless steel mesh in step 11 in acetone, and perform ultrasonic cleaning to remove organic impurities on the surface of the stainless steel mesh to obtain a stainless steel mesh from which organic impurities are removed; wherein, the ultrasonic cleaning time is 30 minutes, and the ultrasonic power is 100W;

[0062] Step 13, immerse the stainless steel mesh for removing organic impurities into a hydrochloric acid solution with a concentration of 3%, and perform ultrasonic cleaning to remove oxide impurities on the surface of the stainless steel mesh to obtain a stainless steel mesh for removing oxides; wherein, the...

Embodiment 2

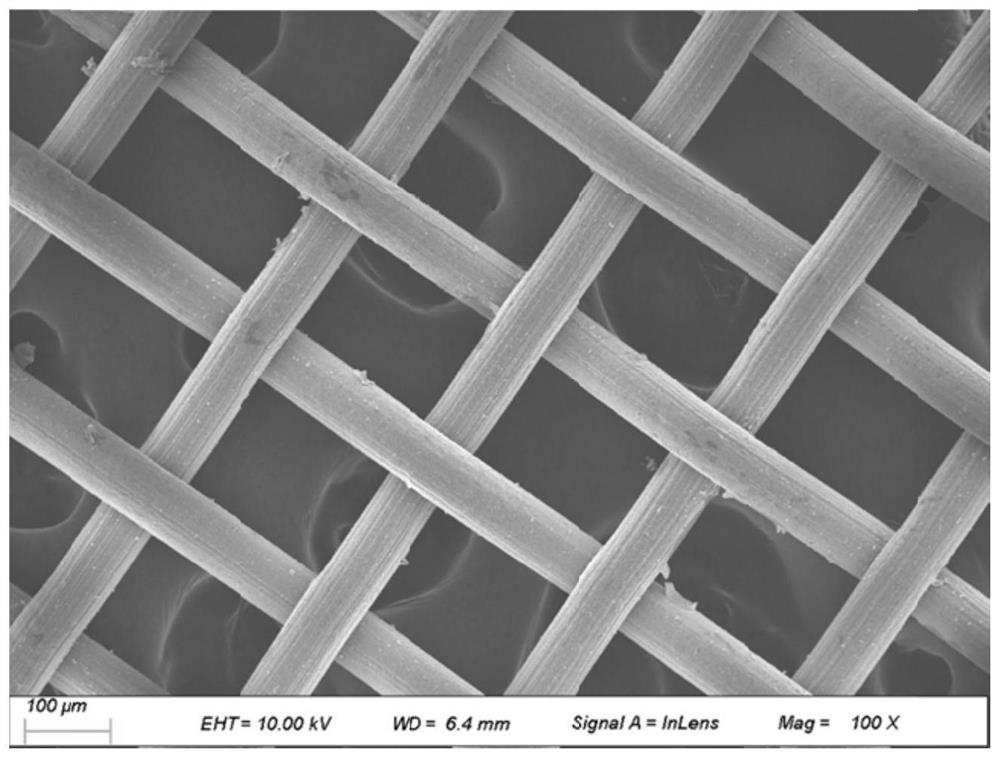

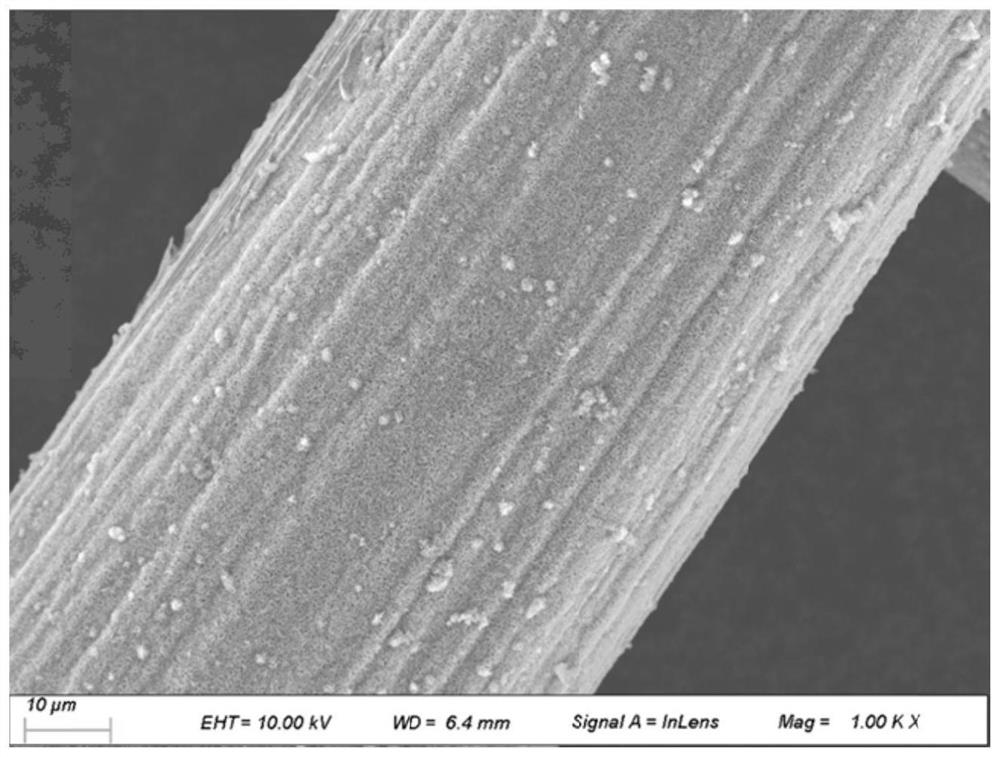

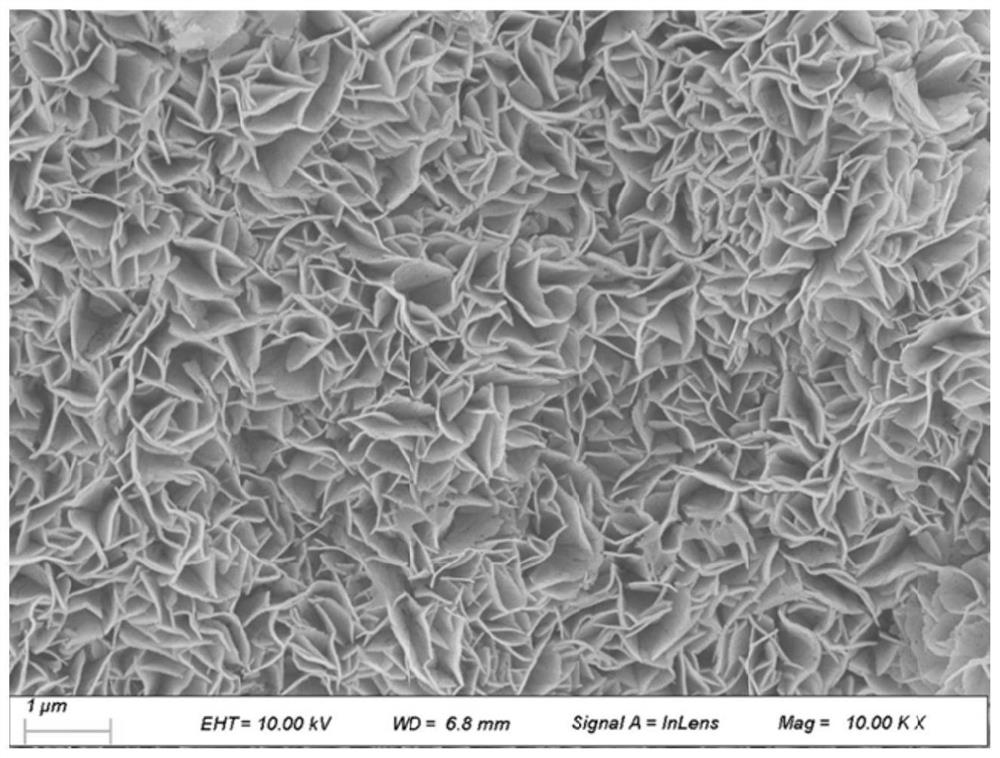

[0077] The difference from Example 1 is that: according to the preparation method of Example 1, the stainless steel mesh aperture is adjusted to 200 mesh or 400 mesh, and other conditions remain unchanged; the Co prepared in Example 2 3 o 4 Nanosheet-loaded stainless steel mesh, Co 3 o 4 The nanosheets are phase-pure spinel-type Co 3 o 4 , and the shape and attached figure 1 Similarly, the corresponding properties of the light-to-heat conversion stainless steel mesh obtained in Example 1 can be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com