A kind of production and processing technology of touch LCD screen

A processing technology and liquid crystal screen technology, applied to lighting and heating equipment, liquid cleaning methods, furnaces, etc., can solve the problems of poor cleaning effect and low work efficiency, save labor, improve service life, and facilitate replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

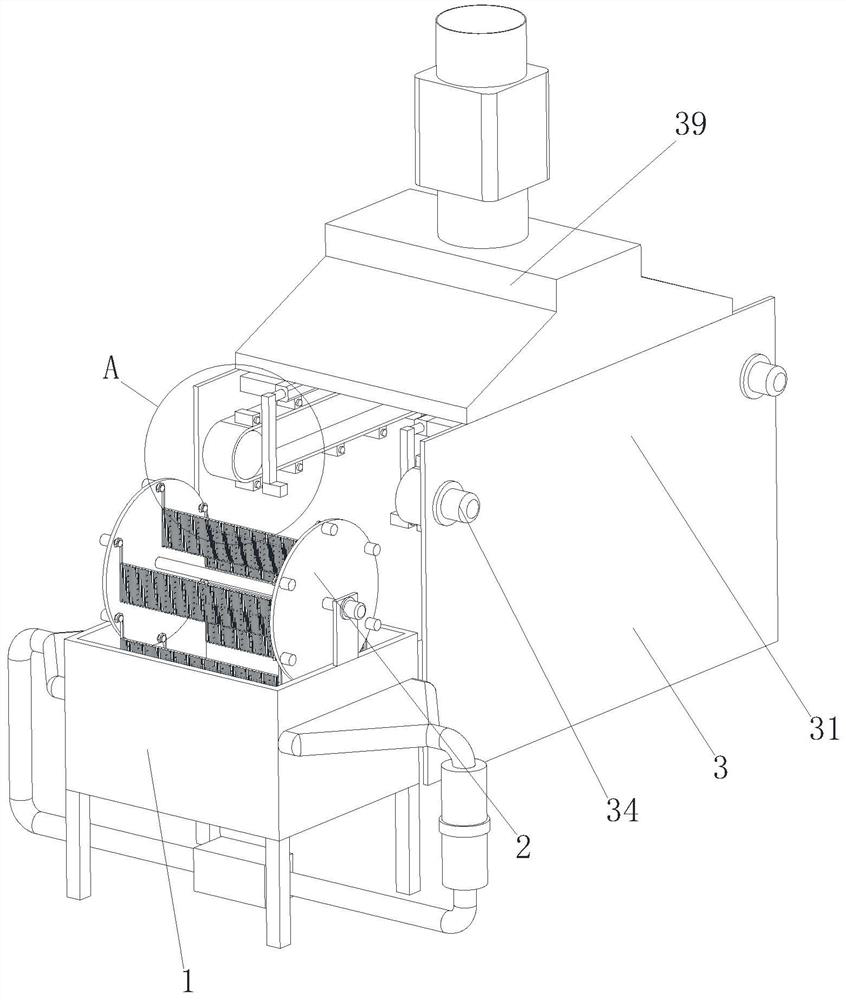

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

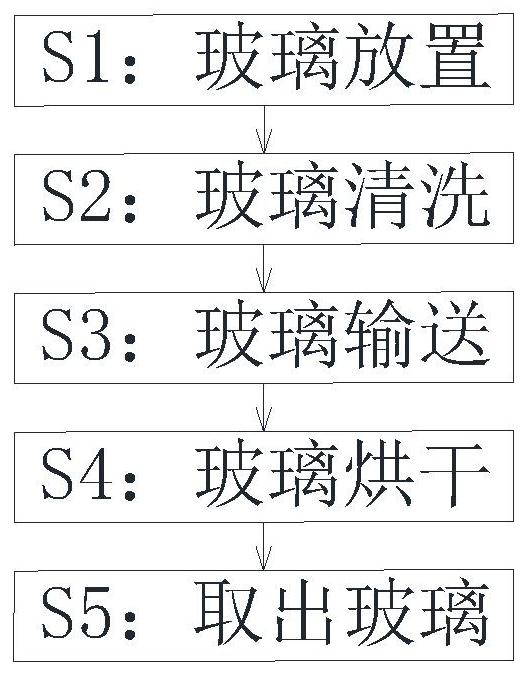

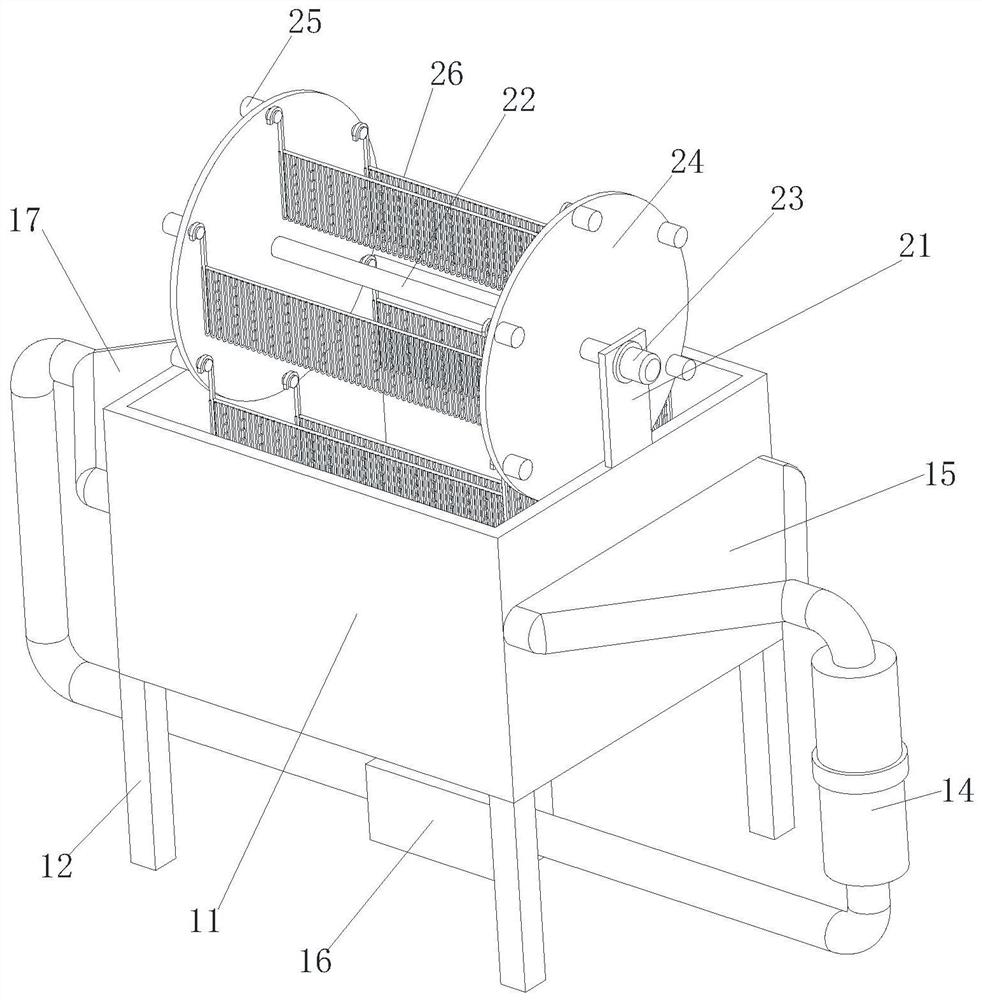

[0033] Referring to 1-8, a touch LCD screen produces a manufacturing process, which uses a touch LCD production and manufacturing processing equipment, which includes a cleaning mechanism 1, a rotating placement mechanism 2 and a conveying The drying mechanism 3, and the cleaning mechanism 1 is provided with a rotating placement mechanism 2, and the conveying drying mechanism 3 is disposed on the rear side of the cleaning mechanism 1; wherein:

[0034] The rotating placement mechanism 2 includes a second mounting frame 21, a rotating shaft 22, a No. 1 drive motor 23, a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com