An electroplating jig for shielding tip effect

A technology of electroplating fixtures and tip effects, which is applied in the direction of electrolytic components and electrolytic processes, can solve the problems of unsatisfactory coating and thickness, and achieve the effects of saving electroplating time, improving production efficiency, and uniform plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

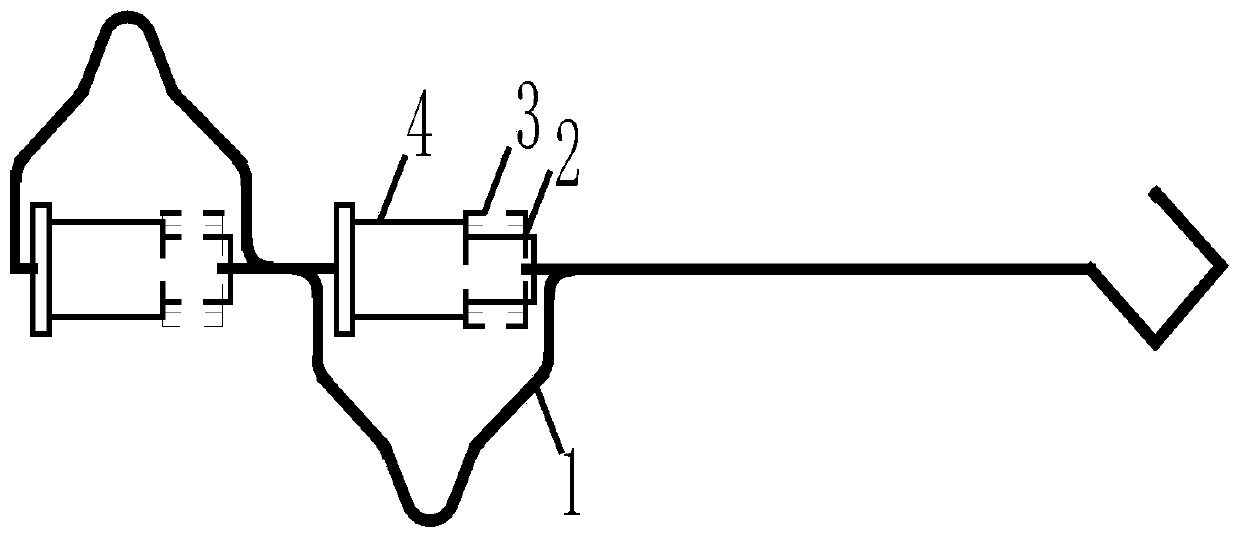

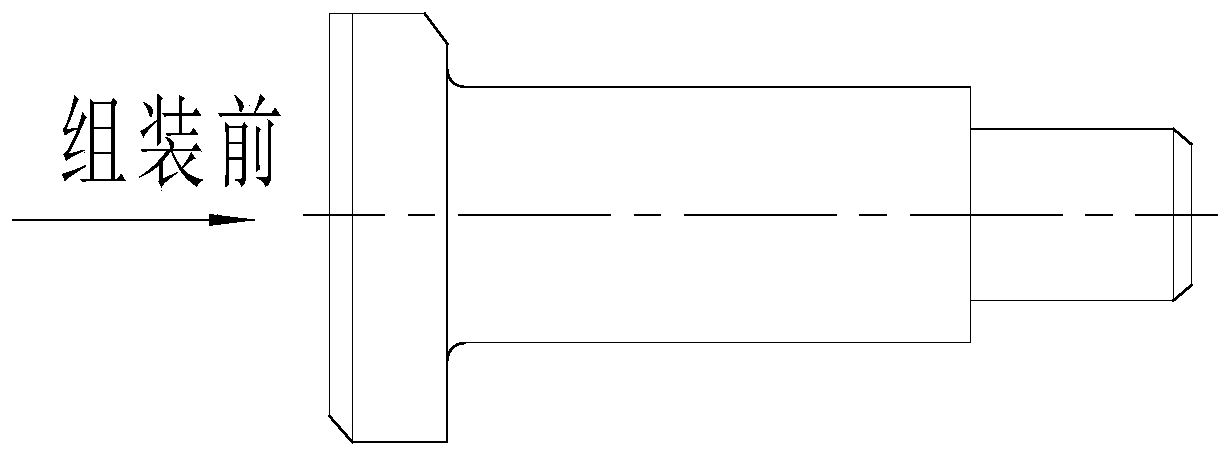

[0013] Partial electroplating is carried out to the bolt whose specification is M5*30, and it is electroplated by using the present invention. Among them, the diameter of the shank of the bolt that needs electroplating is 12MM, and the diameter of the shank that does not need electroplating is 6.5MM, and the length is 15MM.

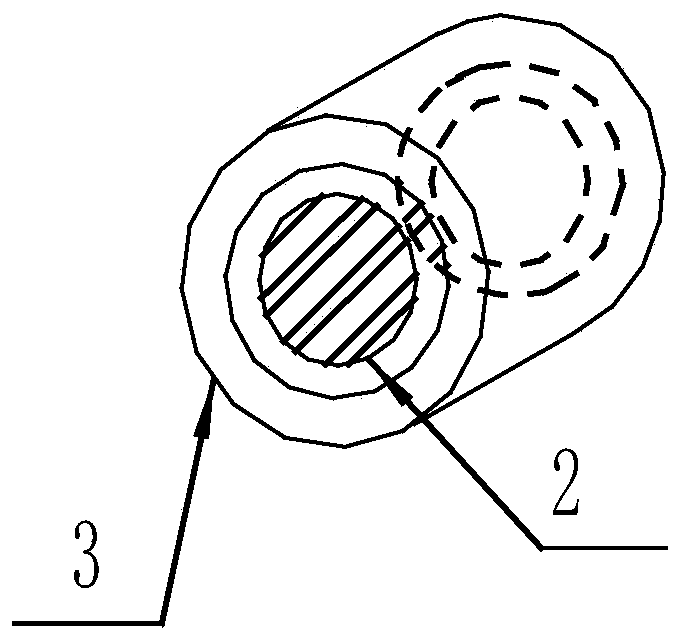

[0014] The electroplating fixture used is composed of an outer ring (3) made of PP material, an insulating inner ring (2) made of thermoplastic tubes, and a copper hook (1). Among them, the entire surface of the copper hook (1) is painted with insulating paint for insulation; the inner diameter of the inner ring (2) of the thermoplastic pipe insulation is 6MM, and the inner diameter of the outer ring (3) made of PP material is 10MM, Their wall thickness is 2MM, and the length is 16-18MM. During use, first put the plastic insulating inner ring (2) on the non-plated rod of the part, then put the outer ring (3) made of non-conductive material on the plastic...

Embodiment 2

[0016] Partial electroplating is carried out on the bolts with the specification of M12×60. The diameter of the shank of the bolt that needs to be electroplated is 23MM, and the diameter of the shank that does not need electroplating is 17.5MM, and the length is 15MM.

[0017] The electroplating fixture used is composed of an outer ring (3) made of PVC material, an insulating inner ring (2) of thermoplastic tubes, and a copper hook (1). Wherein copper hook (1) entire structural surface is brushed with insulating varnish, is insulated; The inner circle diameter of thermoplastic tube insulating inner ring (2) is 18MM, the inner circle diameter of PP material outer ring (3) is 22MM, Their wall thickness is 2MM, and the length is 16-18MM. During use, first put the plastic insulating inner ring (2) on the non-plated rod of the part, then put the outer ring (3) made of non-conductive material on the plastic insulating inner ring (2), and finally put the two ends of the part It is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com