Method for preparing activated charcoal by utilizing coal-made activated charcoal furnace

A technology for preparing activated carbon and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc. It can solve the problems of environmental pollution, waste of resources, and unreasonable and effective use of production capacity, and achieve high yield and high efficiency. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

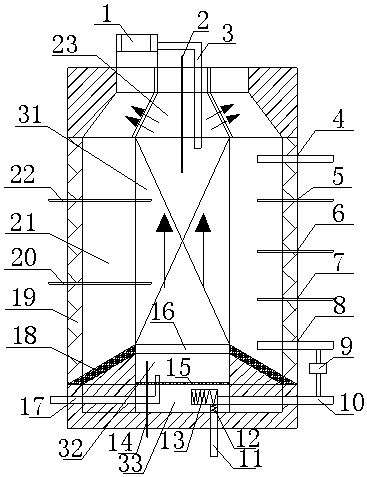

[0033] The specific implementation manners of the present invention will be further described below.

[0034] Implement a kind of coal-based activated carbon stove and prepare activated carbon method, the preparation method of described activated carbon is to carry out according to the following steps:

[0035] First, crush and mix 100g of lignite and 600g of weak caking coal, then extrude it under the pressure of 130Mpa, then crush the molding material to 3mm, and put it into the drying room of the raw material feeding room through the feeding equipment for drying. The temperature of the drying room is determined by the reaction Part of the hot gas generated by the combustion of natural gas in the furnace is provided, and the temperature of the drying room is controlled at 100°C for 60 minutes of drying.

[0036] Then the dry material enters the reaction unit for carbonization and activation under the action of gravity;

[0037] Then set the reaction temperature, reaction ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com