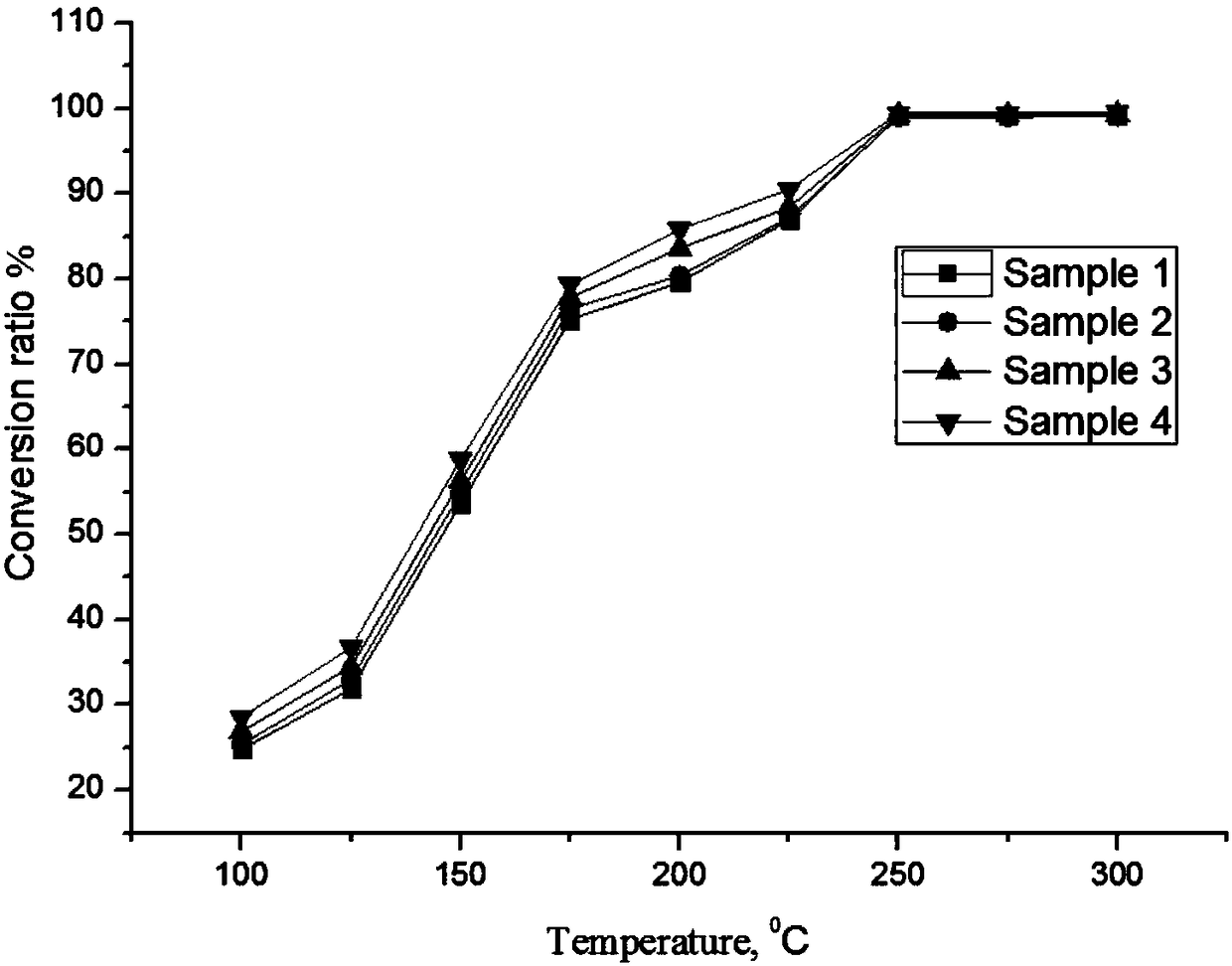

Catalytic combustion catalyst containing manganese-cerium-titanium-hafnium composite oxide and preparation method and application of catalytic combustion catalyst

A composite oxide, catalytic combustion technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, combustion method, physical/chemical process catalyst, etc. To achieve the effect of easy large-scale industrial production, simple process, and easy sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

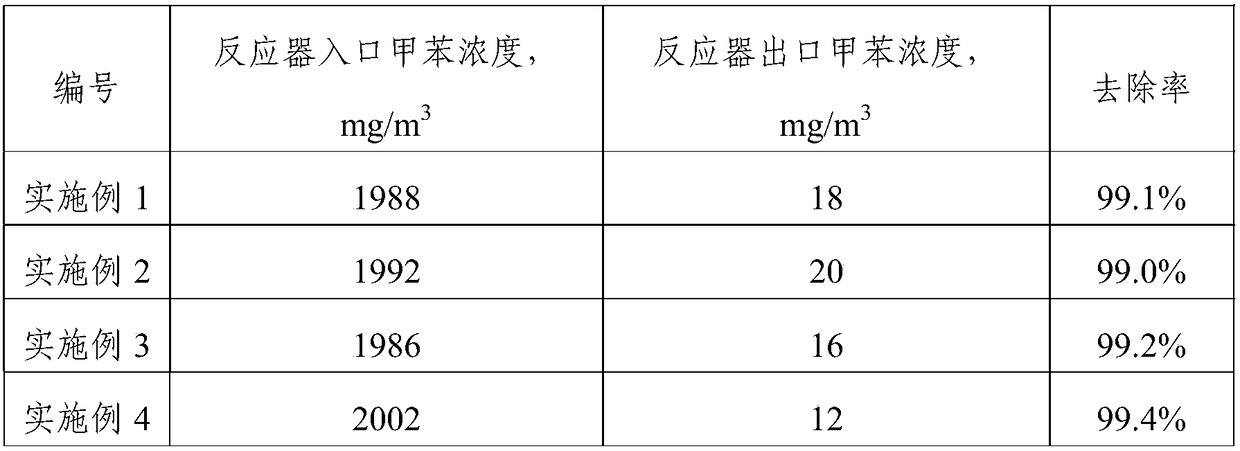

Examples

Embodiment 1

[0031] This example provides a catalyst containing manganese-cerium-titanium-hafnium composite oxide, which is prepared by the following method:

[0032] (1) Place the cordierite honeycomb ceramic carrier in dilute nitric acid with a mass concentration of 5% and soak for 4 hours, then place it in an ultrasonic cleaner for cleaning for 4 hours, take it out and bake it at 90°C for 4 hours, and then bake it for 5 hours, Obtain the pretreated cordierite honeycomb ceramic carrier;

[0033] (2) Dissolve 64 grams of tetrabutyl titanate in absolute ethanol, slowly add a small amount of water, then add a certain amount of ethylenediamine, and stir magnetically for 1 hour to obtain a stable sol; dissolve 41 grams of hafnium oxychloride to 50 In milliliter formaldehyde solution, stir for 30 minutes to form a uniform solution; then slowly add the solution to the above-mentioned sol, and stir vigorously until the reaction is completed to form a translucent gel;

[0034] (3) 20 grams of Mn...

Embodiment 2

[0037] This example provides a catalyst containing manganese-cerium-titanium-hafnium composite oxide, which is prepared by the following method:

[0038] (1) Soak the cordierite honeycomb ceramic carrier in dilute nitric acid with a mass concentration of 7% for 4 hours, then place it in an ultrasonic cleaner for 3 hours, take it out and bake it at 100°C for 4 hours, and then bake it for 5 hours, Obtain the pretreated cordierite honeycomb ceramic carrier;

[0039] (2) Dissolve 64 grams of tetrabutyl titanate in absolute ethanol, slowly add a small amount of water, then add a certain amount of ethylenediamine, and stir magnetically for 1 hour to obtain a stable sol; dissolve 41 grams of hafnium oxychloride to 50 mL of formaldehyde solution and stirred for 30 minutes to form a homogeneous solution. Then slowly add the solution into the above-mentioned sol and stir vigorously until the reaction is completed to form a translucent gel;

[0040] (3) 25 grams of Mn(NO 3 ) 2 and 30...

Embodiment 3

[0043] This example provides a catalyst containing manganese-cerium-titanium-hafnium composite oxide, which is prepared by the following method:

[0044] (1) Place the cordierite honeycomb ceramic carrier in dilute nitric acid with a mass concentration of 8% for 3 hours, then place it in an ultrasonic cleaner for 3 hours, take it out and bake it at 110°C for 3 hours, and then bake it for 5 hours, Obtain the pretreated cordierite honeycomb ceramic carrier;

[0045] (2) Dissolve 64 grams of tetrabutyl titanate in absolute ethanol, slowly add a small amount of water, then add a certain amount of ethylenediamine, and stir magnetically for 1 hour to obtain a stable sol; dissolve 41 grams of hafnium oxychloride to 50 In milliliter formaldehyde solution, stir for 30 minutes to form a uniform solution; then slowly add the solution to the above-mentioned sol, and stir vigorously until the reaction is completed to form a translucent gel;

[0046] (3) 30 grams of Mn(NO 3 ) 2 (AR) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com