A kind of anti-sintering zirconium pyrophosphate porous ceramic and its preparation method

A technology of porous ceramics and zirconium pyrophosphate, which is applied in the field of sintering-resistant zirconium pyrophosphate porous ceramics and its preparation, which can solve the problems of increasing thermal conductivity of porous materials, increasing the temperature and pressure of the substrate, and sintering of porous materials to achieve strength and thermal conductivity. Good rate, high porosity, small volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

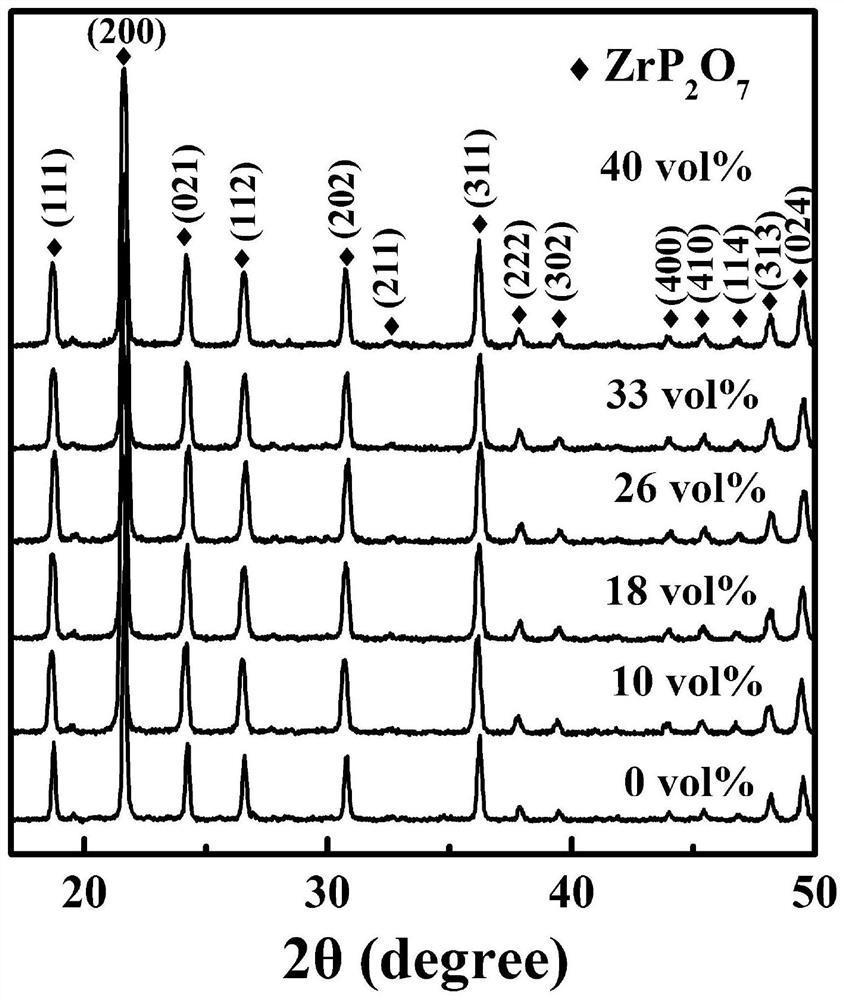

[0026] Zirconium pyrophosphate powder and flour are used as raw materials, wherein the volume content of flour varies from 0% to 40%, and absolute ethanol is used as a medium, mixed with a planetary ball mill for 16 hours, and the uniformly mixed raw materials are vacuum-dried to obtain zirconium pyrophosphate powder and Flour mixed powder is pressed into a disc with a diameter of 15 mm and a thickness of 8 mm by dry pressing. The pressure of dry pressing is 2 MPa. The green body of dry pressing is put into a cold isostatic press for molding, and the forming pressure is 200 MPa. Put the molded sample into a high-temperature air furnace, heat it to 1300° C. at a heating rate of 15° C. / min, and keep it warm for 3 hours to obtain zirconium pyrophosphate porous ceramics. The phase compositions of porous ceramics obtained under different flour volume contents are as follows: figure 1 As shown, the results show that the obtained porous ceramics are pure zirconium pyrophosphate porou...

Embodiment 2

[0028] Zirconium pyrophosphate powder and flour are used as raw materials, wherein the volume content of flour varies from 0% to 40%, and absolute ethanol is used as a medium, mixed with a planetary ball mill for 24 hours, and the uniformly mixed raw materials are vacuum-dried to obtain zirconium pyrophosphate powder and Flour mixed powder is pressed into a disc with a diameter of 20 mm and a thickness of 10 mm by dry pressing. The pressure of dry pressing is 5 MPa. The green body of dry pressing is put into a cold isostatic press for molding, and the molding pressure is 250 MPa. Put the molded sample into a high-temperature air furnace, heat it to 1400° C. at a heating rate of 10° C. / min, and keep it warm for 1.5 hours to obtain a zirconium pyrophosphate porous ceramic with a porosity distribution of 44-60%. figure 2 Shown is the relationship between the porosity and density of zirconium pyrophosphate porous ceramics prepared at 1400°C for 1.5 hours and the volume content of ...

Embodiment 3

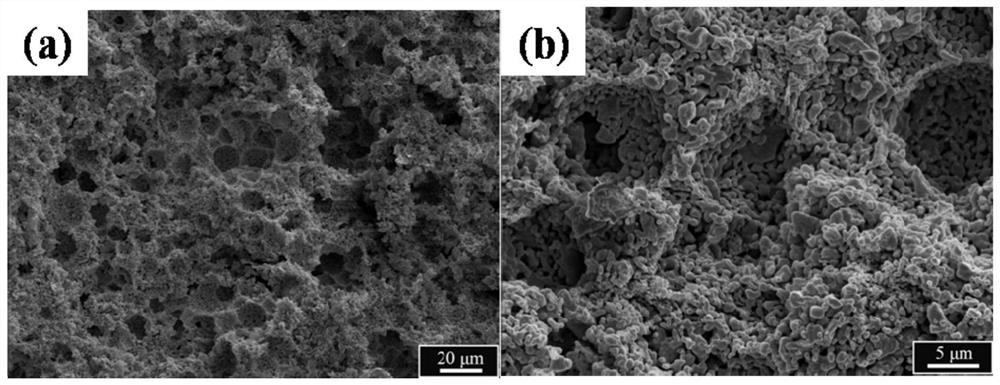

[0030] Use zirconium pyrophosphate powder and flour as raw materials, wherein zirconium pyrophosphate powder is 17.0g, flour is 3.0g, and the volume content of flour is 26%. With absolute ethanol as the medium, use a planetary ball mill to mix for 12 hours, and the evenly mixed raw materials are vacuum Dry to obtain the mixed powder of zirconium pyrophosphate powder and flour, and press it into a disc with a diameter of 30 mm and a thickness of 15 mm by dry pressing. The pressure of dry pressing is 4 MPa, and the dry pressed green body is put into a cold isostatic press Molding, the molding pressure is 150MPa. Put the formed sample into a high-temperature air furnace, heat it to 1350° C. at a heating rate of 20° C. / min, and keep it warm for 2.5 hours to obtain a zirconium pyrophosphate porous ceramic with a porosity of 54%. Microstructure such as image 3 As shown, wherein (a) is a microstructure photo of the pore distribution, wherein the evenly distributed large-diameter po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com