Method for detecting dibromoneopentyl glycol in textiles

A dibromoneopentyl glycol and detection method technology, which is applied in the field of detection of dibromoneopentyl glycol in textiles, can solve cumbersome and time-consuming problems, difficulty in realizing dibromoneopentyl glycol qualitative and quantitative analysis, poor accuracy, etc. problem, to achieve the effect of short separation time, high accuracy and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In the present embodiment, the detection method of dibromoneopentyl glycol in textiles comprises the following steps:

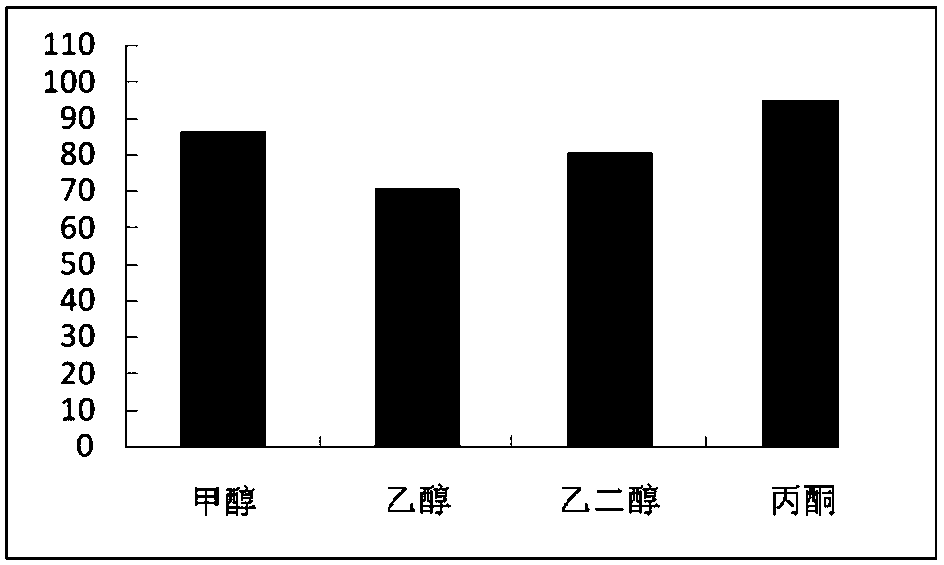

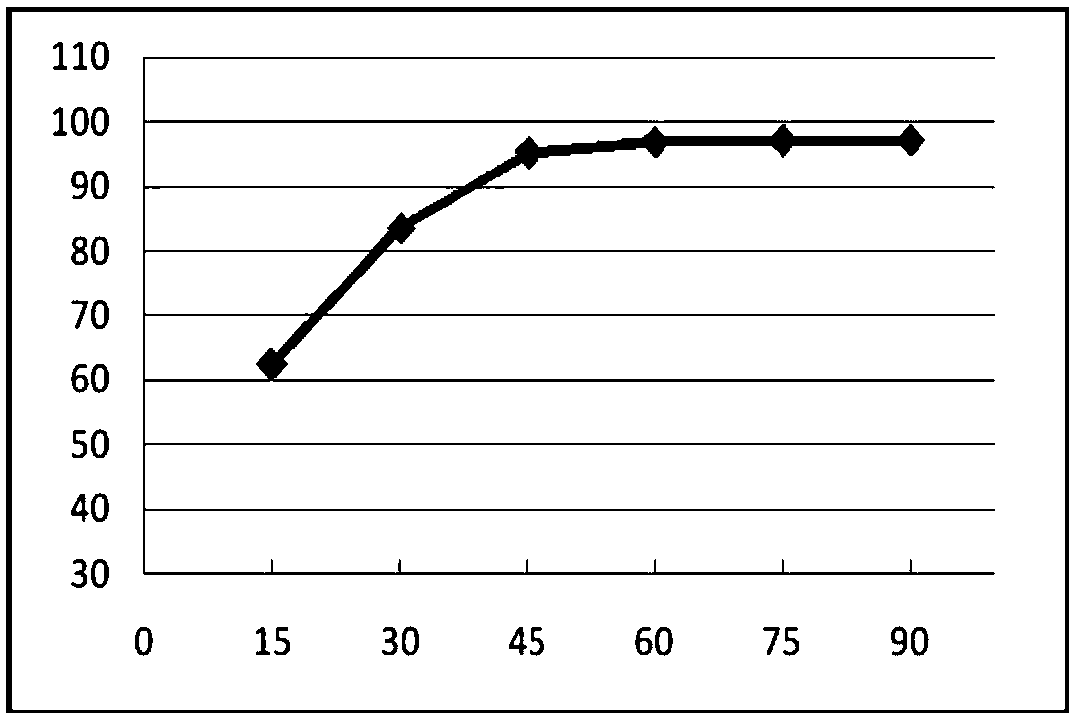

[0050] Sample pretreatment: Take the textile sample to be tested, cut it into 2mm×2mm size, accurately weigh 1.0g, put it into a 60mL sample bottle, add 10mL of acetone accurately, put it in an ultrasonic generator after sealing it with a stopper, ultrasonically extract for 45min, and extract The solution was filtered with a 0.45 μm PTFE microporous membrane, and the filtrate was taken to obtain the solution to be tested.

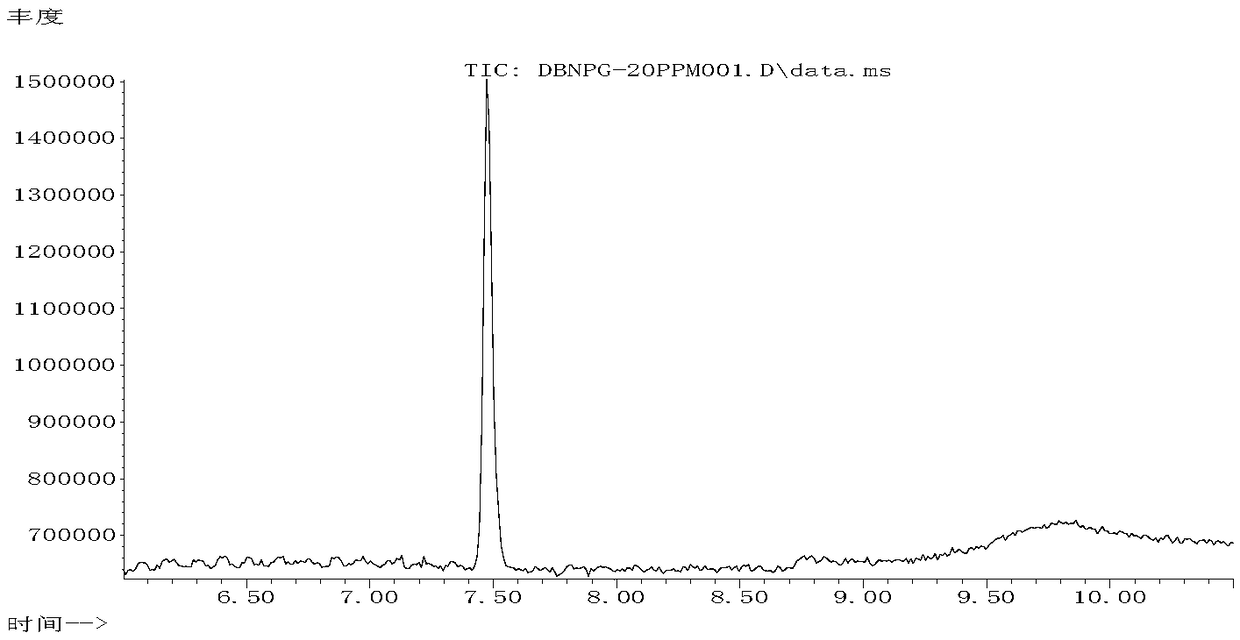

[0051] Gas chromatography-mass spectrometry detection: the filtrate is subjected to gas chromatography-mass spectrometry detection, and the external standard method is used for quantification.

[0052] In this example, the gas chromatography conditions are as follows: chromatographic column: DB-624 capillary chromatographic column: 30m×250μm×1.40μm; heating program: initial temperature of 150°C, keep for 1min, then rise to 250°C, h...

Embodiment 2

[0067] The precision and recovery of the detection method

[0068] Add 0.5mg / L, 5mg / L, 20mg / L 3 levels of concentration to the negative sample respectively and add the standard recovery measurement, according to the gas chromatography-mass spectrometry detection method described in Example 1, repeat the measurement for each addition level 7 times , the results are shown in Table 3.

[0069] The standard recovery and precision (n=7) of table 3 dibromoneopentyl glycol

[0070] Add scalar

[0071] As can be seen from Table 3, under 3 kinds of standard addition levels, its standard addition recovery rate is 99.4%~100.7%, and relative standard deviation (RSD) is 1.9%~3.6%, shows that detection method recovery rate of the present invention is good, High precision. Comparative example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com