Desulfurization method of coke oven gas

A coke oven gas and picric acid technology, which is applied in separation methods, chemical instruments and methods, combustible gas purification, etc., can solve the problem of high risk of picric acid concentration deviating from an appropriate value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0158] Hereinafter, the present invention will be described in detail using examples, but the present invention is not limited to the following examples within the range not exceeding the gist of the present invention.

[0159] First, the method for measuring the concentration of the picric acid reduction product before conversion into the extraction rate will be described using Reference Example 1 below.

reference example 1

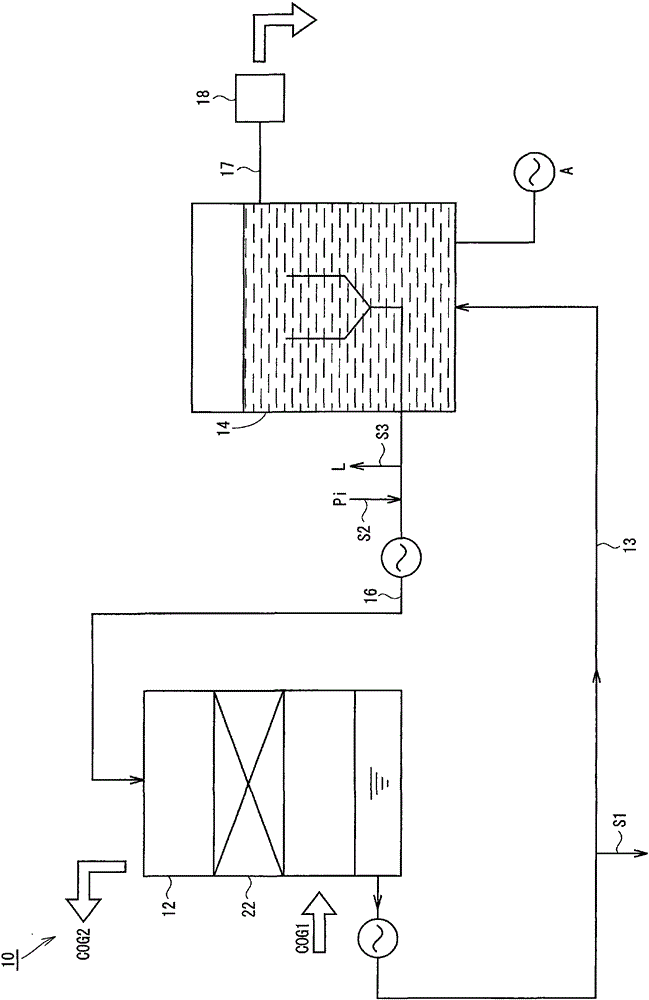

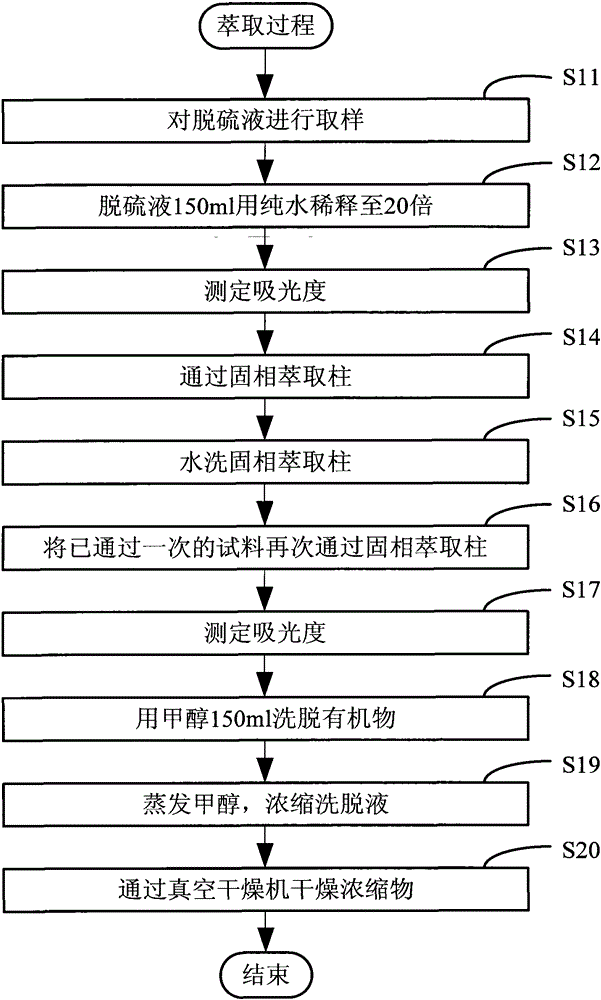

[0161] exist figure 1 In the regeneration tower 14 shown, the regenerated absorption liquid (desulfurization liquid) is sampled from the sampling pipe S3 provided on the piping 16 conveyed to the desulfurization tower 12. figure 2 The extraction procedure shown yields Extract A. As the solid-phase extraction column, a product name "Sep-PakPlusCSP800 (filler: polystyrene resin, particle diameter: 75 to 150 μm)" manufactured by Nippon Wood Co., Ltd. was used. Weigh the extract A to find the concentration of the extract A in the desulfurization liquid. The results are shown in the "F-1 (Inlet)" column of Table 1.

[0162] Table 1

[0163] Amount of solid phase extract (mg / L)

[0164]

[0165]

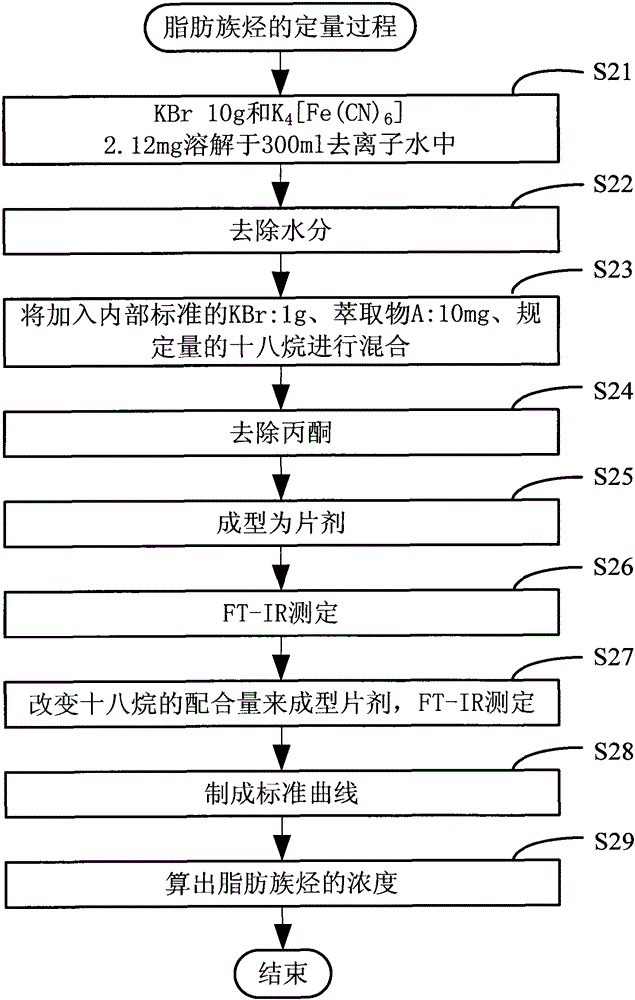

[0166] Using a Fourier transform infrared spectrophotometer (manufactured by JASCO Corporation, product name "FT / IR410"), based on image 3 The quantification process of aliphatic hydrocarbons is shown, obtained by infrared absorption spectra. The measurement of infrared absorp...

Embodiment 1

[0195] The absorption liquid was sampled from the sampling tube S3 at different dates, and the concentration of the picric acid reduction product before conversion of the extraction rate was measured by the same method as in Reference Example 1. The results are shown in Table 4. Table 4 also shows the measurement results of the absorbance at 475 nm of the sample before organic substance extraction and the absorbance at 475 nm of the sample after organic substance extraction. For the measurement, U-2900 (ultraviolet-visible spectrophotometer) manufactured by Hitachi High Technologies, Inc. was used. In addition, the extraction rate (%) is also shown in Table 4. The extraction rate (%) was obtained by the following formula.

[0196] (Extraction rate (%))=(1-((absorbance after extraction) / (absorbance before extraction)))×100

[0197] In addition, in Table 4, the concentration of the picric acid reduction product after conversion of the extraction ratio is also shown. The conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com