Pelletizing-heap bioleaching process suitable for low grade oxygen sulfur mixed copper mine

A mixed copper ore, low-grade technology, applied in the direction of process efficiency improvement, etc., can solve the problems of poor permeability, and achieve low production cost, good permeability, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

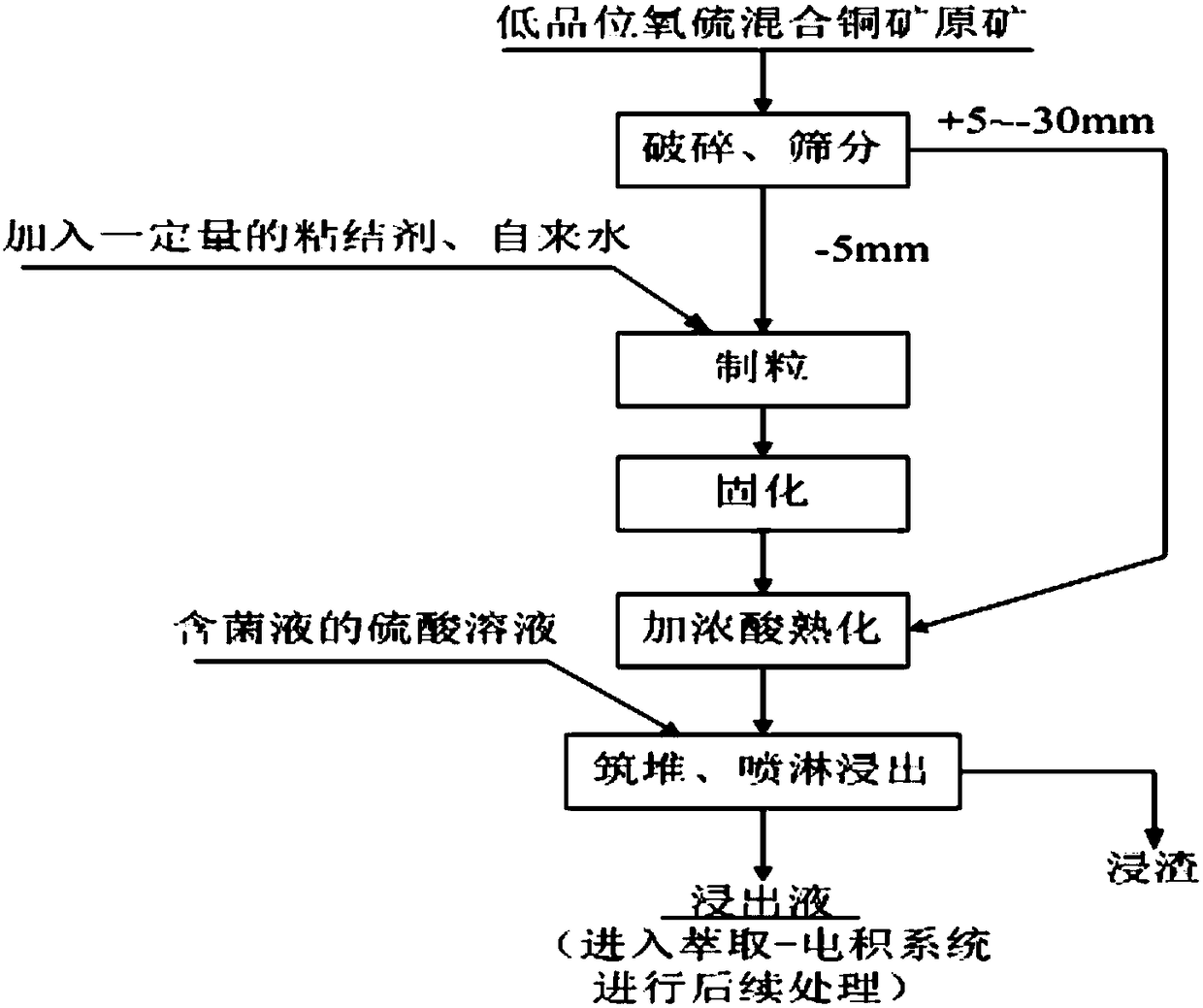

Method used

Image

Examples

Embodiment 1

[0040] The oxygen-sulfur mixed copper ore used comes from a certain place in Xinjiang. The results of its chemical multi-element analysis are shown in Table 1, the results of particle size screening of -5mm grain size ore for granulation are shown in Table 2, and the results of phase analysis of copper are shown in Table 1. 3.

[0041] Table 1 Analysis results of main elements of oxygen-sulfur mixed copper ore

[0042] element

Cu

Fe

S

Ca

Mg

Al

content / %

0.77

5.10

0.22

7.60

1.79

8.22

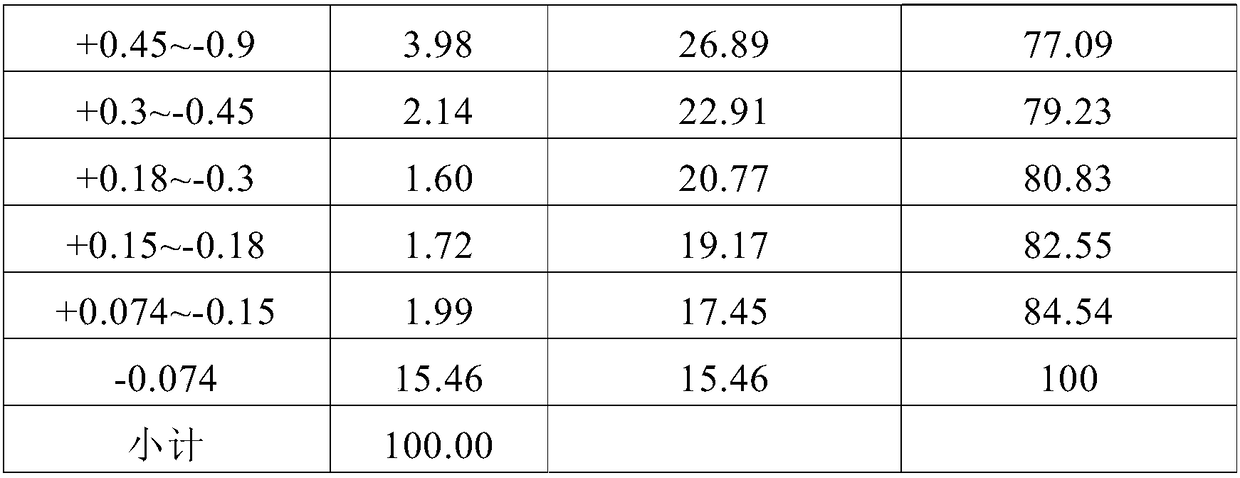

[0043] Table 2 - 5mm particle size ore particle size screening results for granulation

[0044]

[0045]

[0046] Table 3 Copper Phase Analysis Results of Oxy-Sulfur Mixed Copper Ore

[0047] copper phase

secondary copper sulfide

copper in silicate

total copper

content / %

0.508

0.059

0.183

0.020

0.77

Occupancy / %

65.97

7.66

23.77...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com