Corrosion inhibitor for high-temperature equipment and preparing method of corrosion inhibitor

A technology for high-temperature equipment and corrosion inhibitors, applied in the field of corrosion inhibitors for high-temperature equipment and its preparation, can solve the problems of severe corrosion of high-temperature equipment and ineffective corrosion inhibition effects, and achieve corrosion inhibition, activation energy, and good corrosion inhibition performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

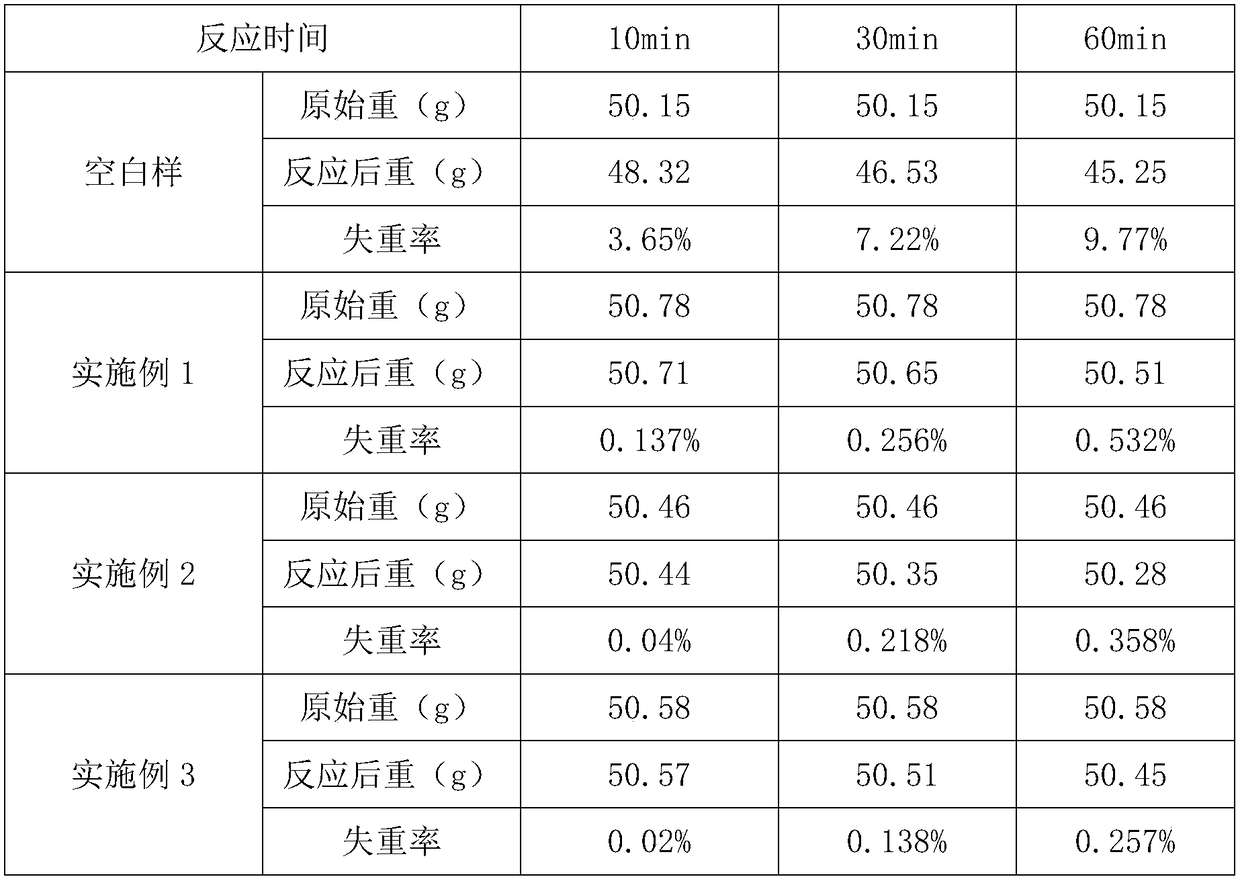

Examples

Embodiment 1

[0028] A corrosion inhibitor for high temperature equipment, comprising the following raw materials by weight:

[0029] 40 parts of organic amines, 30 parts of imidazolines, 20 parts of phosphates, 15 parts of metal hydroxides, 20 parts of phosphate esters and 0.8 parts of surfactants;

[0030] Organic amines react with phosphates to form organic phosphates, and organic phosphates react with metal oxides to form oxoamine phosphates;

[0031] The metal oxide is magnesium hydroxide.

[0032] The organic amine is composed of dicyclohexylamine and ethanolamine in a mass ratio of 1:1.

[0033] Ethanolamine is composed of diethanolamine and triethanolamine in a mass ratio of 2:1.

[0034] The surfactant is composed of alkylbenzene sulfonate and amino acid according to 3:2.

[0035] The imidazoline is composed of imidazoline sunbadate and imidazoline oleate according to the mass ratio of 1.5:1, and the phosphoric acid ester is phosphoric acid diester.

[0036] The present embodim...

Embodiment 2

[0043] A corrosion inhibitor for high temperature equipment, comprising the following raw materials by weight:

[0044] 60 parts of organic amines, 10 parts of imidazolines, 35 parts of phosphoric acid, 25 parts of metal hydroxides, 20 parts of phosphate esters and 5 parts of surfactants;

[0045] Organic amines react with phosphoric acid to form organic phosphates, and organic phosphates react with metal oxides to form oxoamino phosphates;

[0046] The metal oxide is composed of molybdenum hydroxide and zinc hydroxide in a mass ratio of 1:1.

[0047] The organic amine is composed of hexamethylenetetramine and pentamethylenetetramine in a mass ratio of 2:1.

[0048] The surfactant is composed of nonylphenol and octylphenol in a mass ratio of 2:3.

[0049] The imidazolines are imidazoline sebate, and the phosphoric acid esters are phosphoric acid monoesters.

[0050] The present embodiment also discloses a preparation method of a corrosion inhibitor for high temperature equi...

Embodiment 3

[0057] A corrosion inhibitor for high temperature equipment, comprising the following raw materials by weight:

[0058] 55 parts of organic amines, 18 parts of imidazolines, 25 parts of phosphoric acid, 22 parts of metal hydroxides, 19 parts of phosphate esters and 2.6 parts of surfactants;

[0059] Organic amines react with phosphoric acid to form organic phosphates, and organic phosphates react with metal hydroxides to form oxoamino phosphates;

[0060] Metal hydroxide ferric hydroxide and zinc hydroxide are composed of 1:1 mass ratio.

[0061] The organic amine is composed of ethanolamine, aromatic amine and melamine according to the mass ratio of 1:3:1.

[0062] Ethanolamine is monoethanolamine.

[0063] The surfactant is soap.

[0064] The imidazolines are imidazoline sebate, and the phosphoric acid esters are phosphoric acid monoesters.

[0065] The present embodiment also discloses a preparation method of a corrosion inhibitor for high temperature equipment, compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com