Internal combustion engine temperature regulator

A technology of temperature regulator and internal combustion engine, which is applied in the direction of engine components, machine/engine, engine cooling, etc. It can solve the problems affecting the heat dissipation of the internal combustion engine, the damage of the limit switch, and the complicated structure, so as to achieve safe performance, prolong service life, Avoid the effect of boiling the pot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

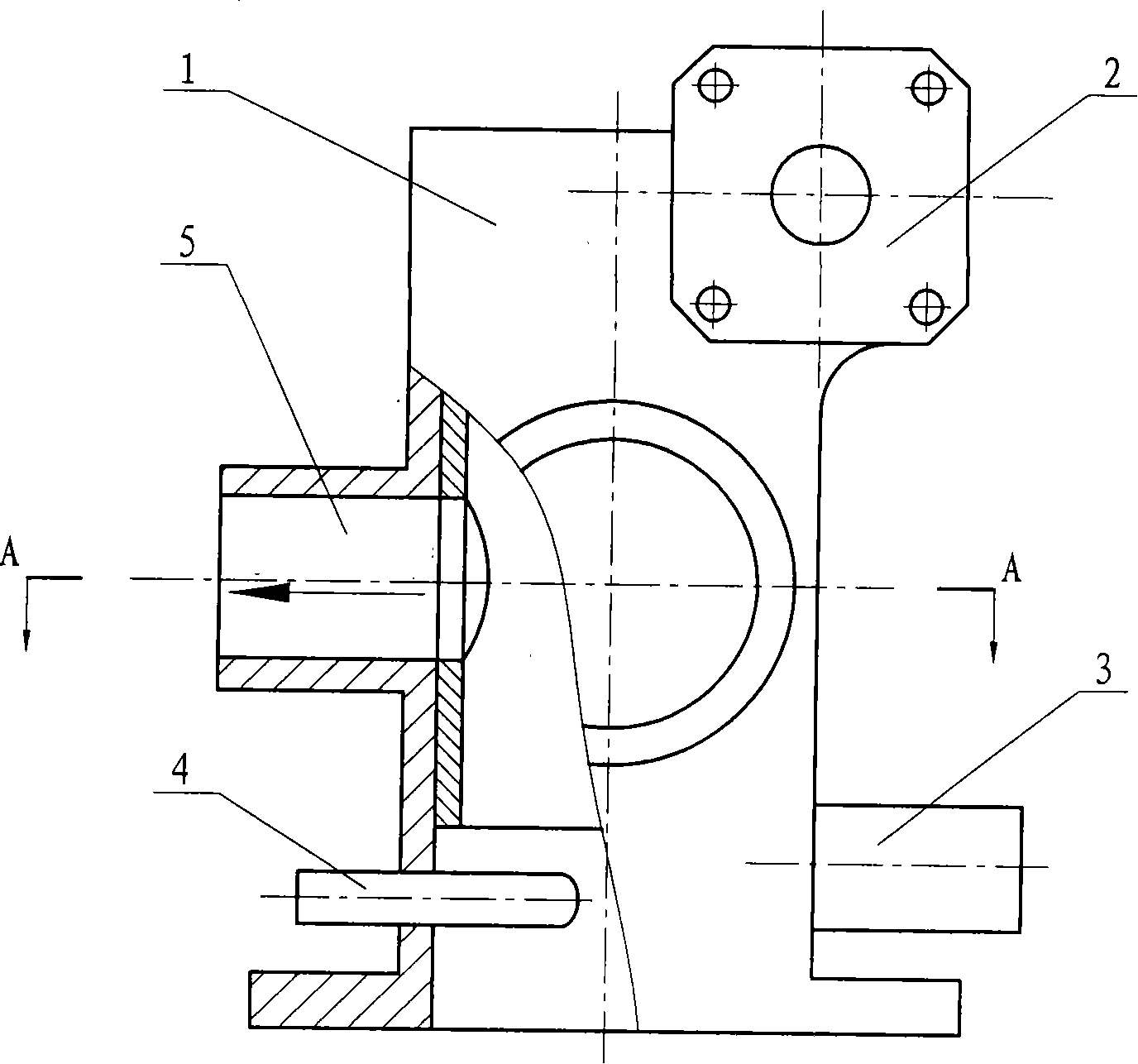

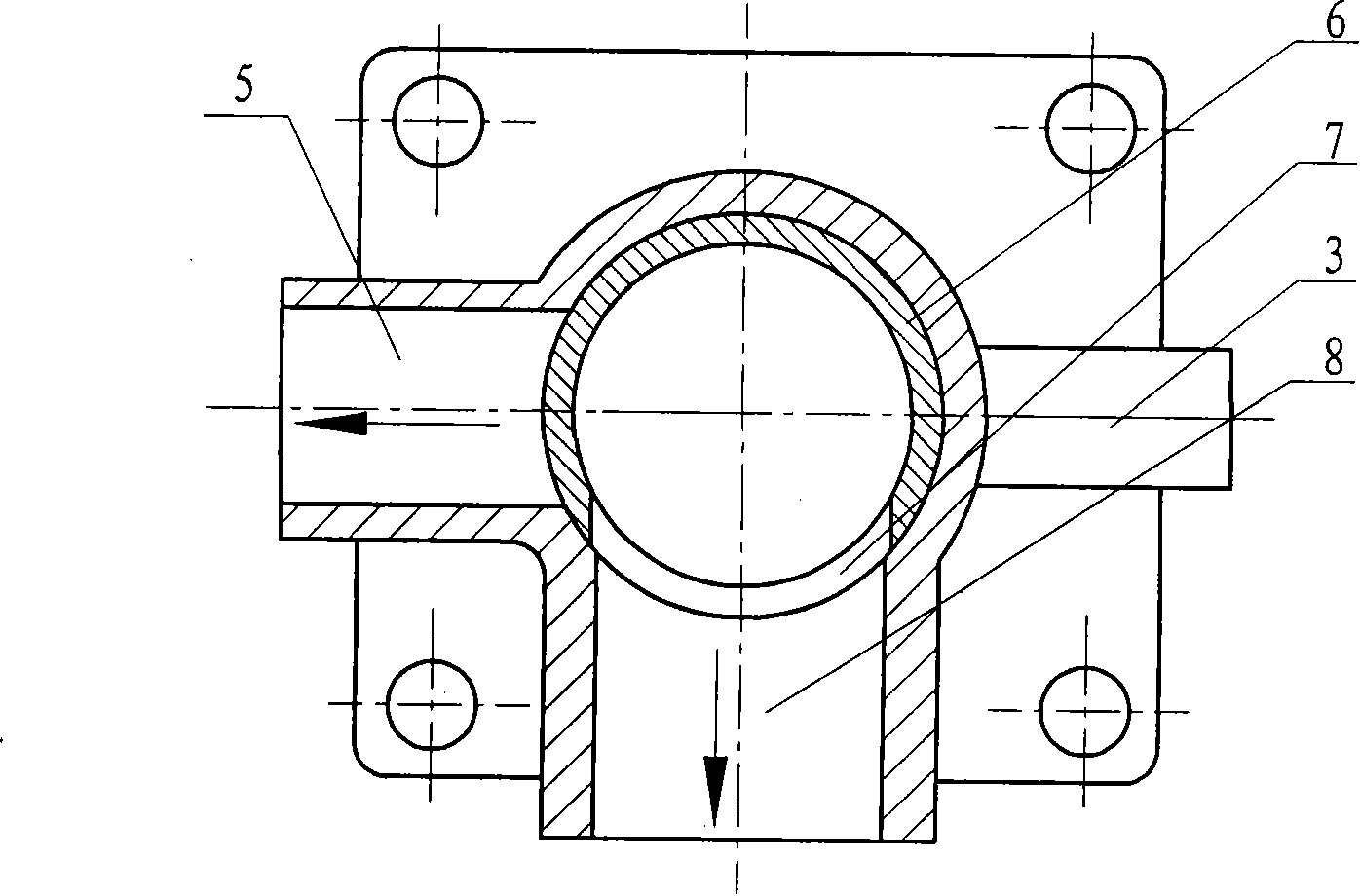

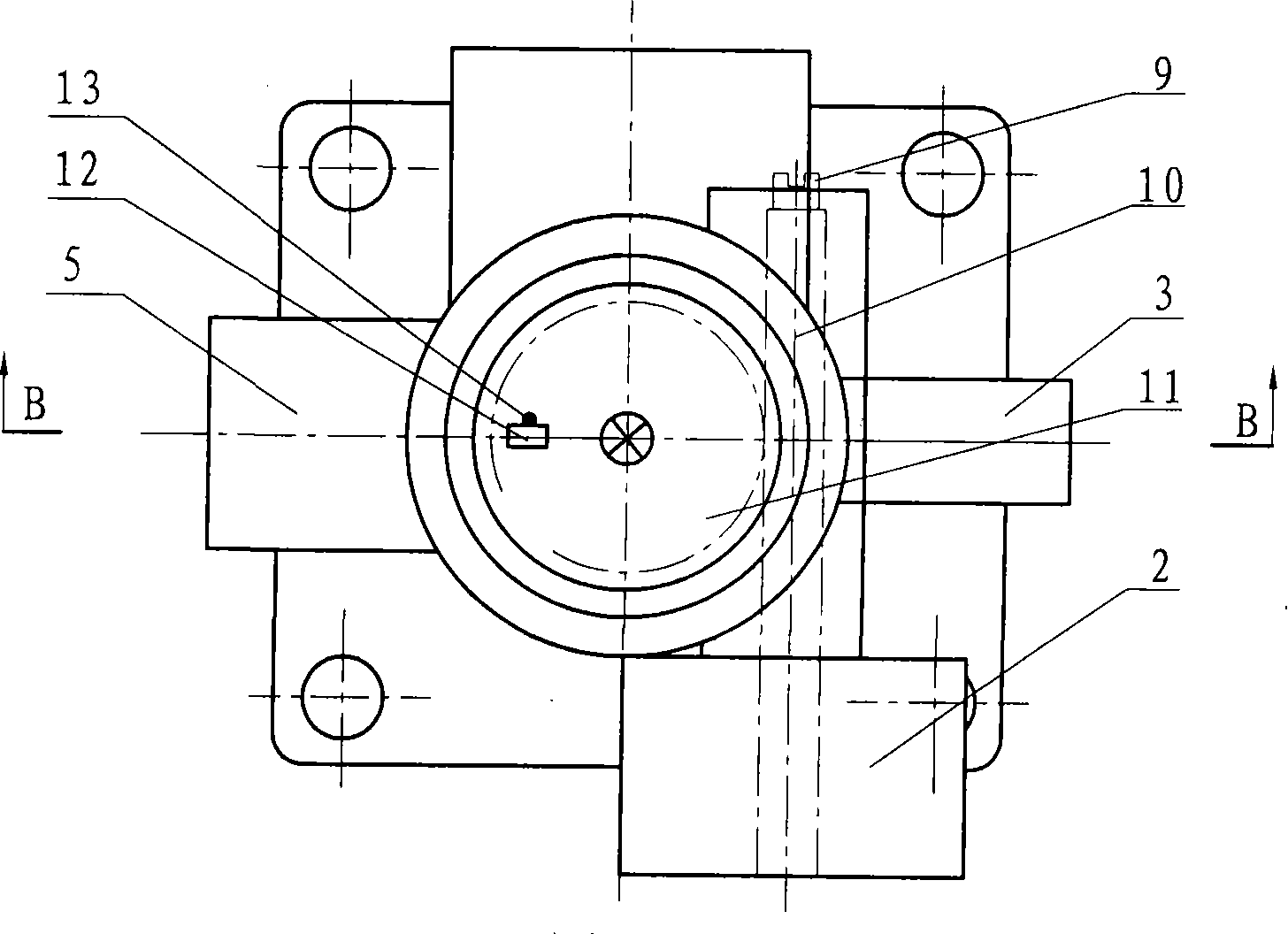

[0026] The present invention will be further described below in conjunction with the accompanying drawings:

[0027] like figure 1 , 2, 3, 4, 5, 6, 1. Three-way valve body of temperature regulator, 2. Stepper motor, 3. Spare interface, 4. Temperature sensor, 5. Small circulating water outlet, 6. Rotor, 7. Rotor cooling water outlet, 8. Large circulation water outlet, 9. Manual safety knob, 10. Worm, 11. Worm gear, 12. Limit switch, 13. Limit post, 14. Valve body cover, 15. Worm gear Fixing nut, 16. Rotor shaft, 17. Shaft sleeve, 18. Mechanical seal, 19. Connecting flange, 20. Rotor inner cavity, 21. Rotor fixing nut, 22. Gearbox, 23. Microcomputer control box, 24 . Temperature display window, 25. Temperature setting button, 26. Radiator, 27. Radiator inlet pipe, 28. Internal combustion engine temperature regulator valve, 29. Body cooling water jacket, 30. Water pump, 31. Body, 32. Radiator return pipe, 33. Small circulation return pipe.

[0028] The temperature sensor insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com